Checking the steering wheel play

With the vehicle stationary, with the wheels in the straight ahead position, rock the steering wheel from side to side with a little effort

If the play exceeds the allowable value (Fig. 1), repair it.

Maximum play: 30 mm.

Checking the power steering fluid level

Put the car on a horizontal plane.

With the engine off, check the fluid level and top up if necessary.

Working fluid: ATF DEXROPf II or III.

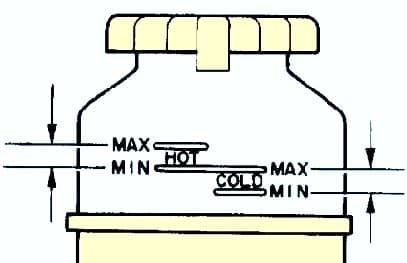

If the working fluid is warm, the fluid level is in the "HOT" interval on the tank or dipstick, if it is cold - in the "COLD" interval.

Warm up the working fluid.

Start the engine and set the idle speed.

Turn the steering wheel several times from lock to lock to increase the temperature of the working fluid to 80 ° C.

Check for any foaming or emulsification of the liquid.

If foaming or emulsification is present, bleed the power steering system (Figure 3).

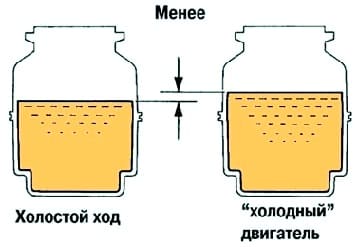

Check for rising fluid levels.

Measure the fluid level with the engine running.

Turn off the engine, wait a few minutes and check the fluid level.

Maximum liquid level increase: 5 mm.

If the increase in fluid level is more than 5 mm, bleed the system.

Check the fluid level again.

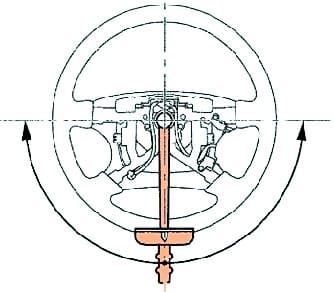

Checking the force on the steering wheel

Check tire pressure, tire type and contact surface before testing.

Set the steering wheel to the center position.

Remove the steering wheel pad.

Start the engine and set the idle speed.

Using a torque wrench, measure the force on the steering wheel in both directions (fig. 5).

Maximum force: 6 Nm.

If the force on the steering wheel is greater than the maximum allowable, repair the power steering.

Tighten the steering wheel nut. Tightening torque: 35 Nm.

Install the steering wheel pad.

Bleeding the power steering system

Check the fluid level in the reservoir.

Raise the front of the car and put it on stands.

With the engine off, turn the steering wheel from lock to lock several times.

Lower the car.

Start the engine and set the idle speed.

Turn the steering wheel from lock to lock, holding it in the extreme position for 2-3 seconds.

Repeat this procedure three to four times.

Turn off the engine.

Check for any foaming or emulsification of the liquid.

If there is foaming or emulsification, check for leaks in the system.

Check the fluid level.

During the inspection, special attention should be paid to the condition of the protective covers and threaded connections.

Torn, cracked, or rubber boots that have lost their elasticity must be replaced, otherwise water, dust or dirt that gets into the nodes will quickly disable them

Check the condition of the hoses and pipelines of the power steering system connecting the pump, reservoir and steering gear

Checking the location of the steering wheel spokes the left wheel, which, with the front wheels in a straight position, should be located symmetrically about the vertical axis.

Otherwise, you need to determine the cause and eliminate it

Turning the steering wheel from lock to lock, we check visually and by ear:

- - reliability of fastening of the steering mechanism and steering wheel;

- - lack of clearance in the tie rod bushings and ball joints of the tie rod ends;

- - the reliability of tightening and locking the bolts for fastening the rods to the rail and the nuts of the fingers of the ball joints;

- - lack of jamming and interference preventing the steering wheel from turning

If you find knocking and sticking, disconnect the tie rods from the steering knuckles and recheck.

If knocks and jamming do not stop, remove the steering gear from the car and repair it

Checking the condition of the protective covers of the tie rod ends.

Replace torn, cracked or loose covers

Sharply turning the steering wheel in both directions (this should be done by an assistant), we check visually and aurally the right and left mountings of the steering mechanism.

Movement of the mechanism and knocks are not allowed

Check for play in the ball joints of the tie rod ends.

We replace the tips, the hinges of which have a noticeable play.

Checking the tightness of the nuts of the ball joints of the tie rod ends