We replace the receiver gasket in case of leakage, while the engine runs unevenly “troit”

We prepare the car for the task, remove the decorative engine cover and disconnect the negative battery terminal

Draining coolant from the engine cooling system

We remove the windshield wiper trapezoid, as described in the article - Toyota Camry windshield wiper and washer repair

Remove the front panel of the air intake box by unscrewing the nuts and unscrewing the bolts of its fastening

Remove the air filter cover assembly with the air supply sleeve

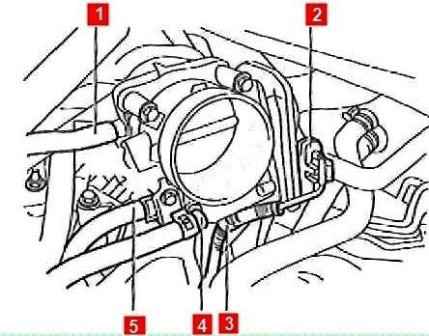

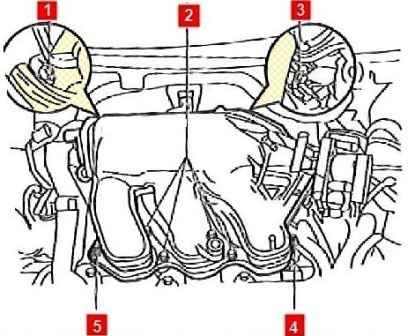

Disconnect hose 1 of the adsorber purge valve from the throttle body

Squeezing the latches, disconnect block 2 of the wiring harness from the throttle assembly, then remove holder 3 of the harness from the throttle assembly and move the wiring harness to the side

We squeeze the bent ears of the clamp and move the clamp along the hose 4 of the engine cooling system, disconnect the hose from the throttle assembly. Also disconnect the hose 5

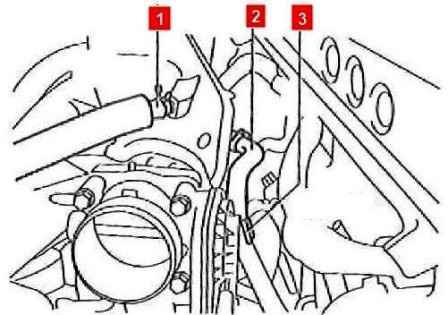

Squeeze the bent ears of the clamp and slide the clamp along the hose 1 of the crankcase ventilation system, disconnect the hose from the receiver

We also disconnect the vacuum hose 2 and remove it from the holder 3

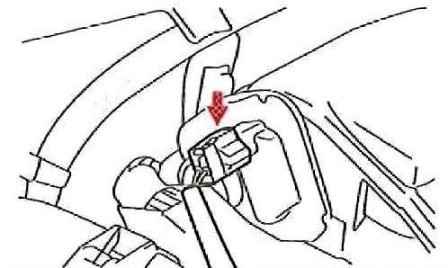

Squeezing the latch, disconnect the wire block from the intake manifold damper actuator

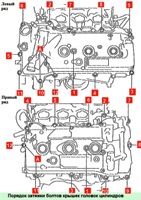

Unscrew four bolts 2, unscrew nuts 4 and 5 securing the receiver to the intake manifold

We unscrew the bolts 1 and 3 securing the receiver to the racks, after which we remove the receiver assembly with the throttle assembly and three gaskets installed under it

Installing the receiver with new gaskets

When installing, first tighten bolts 2 to 18 Nm, then nuts 4 and 5 to 16 Nm.

After that, tighten the bolts 1 and 3 securing the receiver to the racks with a torque of 21 Nm

Install all parts in reverse order

Oil pan seal replacement

Oil pan flange installed with sealant, no gasket of any kind.

Therefore, in case of oil leakage in the oil sump and sump connector, tightening the sump mounting bolts will not lead to the desired result

Remove the engine mudguard by placing the car on a lift or inspection ditch

Drain the oil from the engine lubrication system

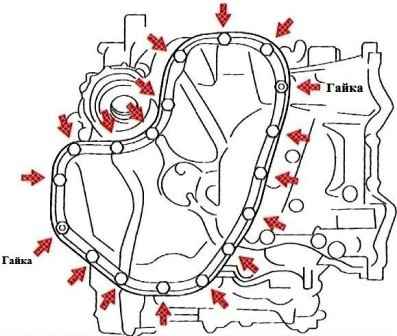

We unscrew sixteen bolts and unscrew the two nuts securing the sump to the oil sump, and then remove the sump

We clean the mating surfaces of the sump and oil sump from the old sealant

We apply a special sealant (Three Bond 1207B or its equivalent) to the mating surface of the oil pan with a roller with a diameter of 3-4 mm, while the sealant application line should pass from the inside of the mounting holes

No later than three minutes after applying the sealant, install the pan on the oil sump, tighten the bolts and fastening nuts to a torque of 10 Nm

Fill engine oil

Fill and start the engine no earlier than two hours after installing the oil pan. This time is necessary for polymerization sealant.