DENSO FK20HR11 spark plugs are used on the 2GR-FE engine, the gap between the spark plug electrodes is 1.0-1.1 mm

To replace the candles, remove the decorative engine cover

Disconnect the negative battery terminal

Draining coolant from the engine cooling system

Remove the intake manifold receiver assembly with the throttle assembly, as described in the article - Replacing the gaskets of the receiver and pan 2GR-FE Toyota Camry

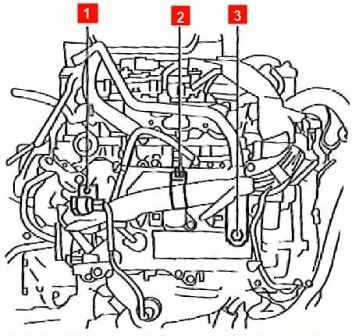

We unscrew the bolt 1 fastening the holder of the oxygen concentration sensor wire harness

Disconnect the clamp 2 fastening the wires of the ignition coils

We unscrew the bolt 3 of the intake manifold receiver strut and remove the strut

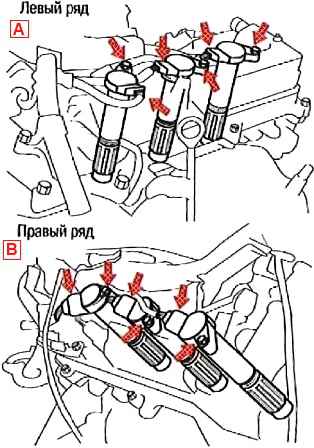

Disconnect the wiring harness pads from the ignition coils and remove the coils from the spark plugs

Blow out the candle wells with compressed air to avoid dirt getting into the cylinders when turning out the candles

Unscrew the candles and remove them from the candle wells

Inspecting the candles and assessing their condition

Check the gap between the electrodes of the candles with a round probe.

The gap should be 1.0-1.1 mm. If the gap is not within this interval, replace the candle

It is forbidden to adjust the gap by bending the side electrode

When installing the spark plugs, we first screw them in by hand (with a wrench without a wrench), and then tighten with a torque of 18 Nm

Install all removed parts in reverse order

Replacing the gaskets of the cylinder head covers of the 2GR-FE engine

We replace the cylinder head gaskets when oil leaks from under the covers, if tightening the bolts fails to eliminate the leak

Remove the decorative engine cover and disconnect the negative battery terminal

Draining coolant from the engine cooling system

Remove the intake manifold receiver assembly with the throttle assembly

Remove ignition coils

Disconnect the wiring harness pads from the two valves of the variable valve timing system and the two camshaft position sensors located on the cylinder head cover whose gasket needs to be replaced

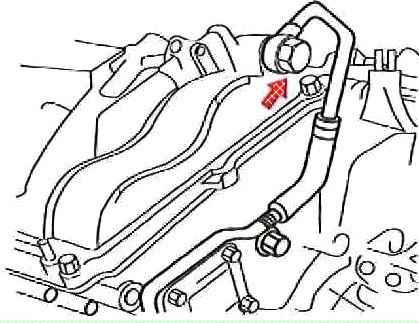

We unscrew the bolt-fitting of the oil pipeline to the cylinder head cover, the gasket that needs to be replaced

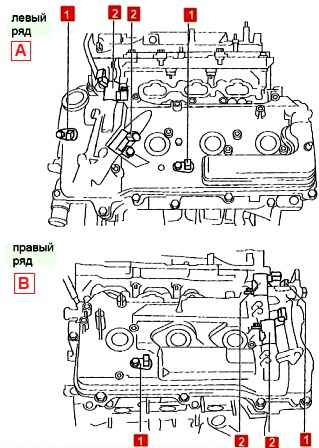

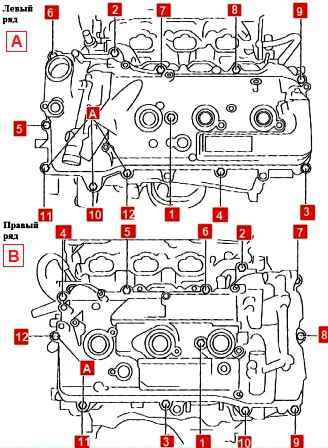

We unscrew the twelve bolts of the cylinder head cover, the gasket that needs to be replaced

Remove the gasket from the grooves of the cover

Clean the grooves of the cover and install a new gasket in the grooves

We replace the O-rings of the oil channels with new ones

Install the cylinder head cover and all removed parts in reverse order

We tighten the cover fastening bolts in the order shown in the figure. The tightening torque for bolts A is 21 Nm, the remaining bolts are 10 Nm.