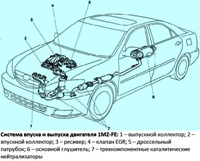

The 1MZ-FE engine is a six-cylinder, V-twin, 3-litre, DOHC, 24-valve engine developed from the previous generation Camry 1MZ-FE engine (Table 1)

The design of this engine has been optimized to improve performance, fuel efficiency and reduce harmful emissions in the exhaust gases, and has the following features:

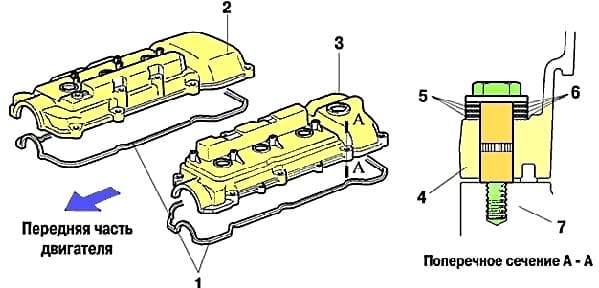

Cylinder head cover

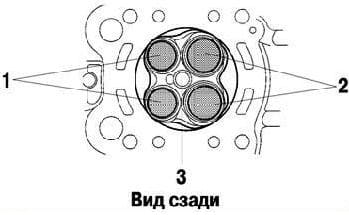

The shoulder bolts (fig. 1) that secure the cylinder head covers are equipped with aluminum washers made from vibration damping laminated aluminum sheet.

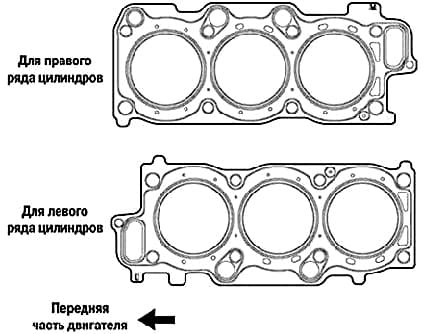

Cylinder head gasket

A metal cylinder head gasket is used to provide pressure resistance and increase sealing properties.

Cylinder head

The cylinder head is made of aluminum and has wedge-shaped combustion chambers.

The spark plug is located in the center of the combustion chamber.

The intake and exhaust valves are angled at a sharp 22.5° angle for a compact cylinder head.

Small diameter inlets are vertical.

The amount of protrusion of the valve guide into the intake port has been reduced by reducing the valve stem diameter and the outside diameter of the valve guide.

Bolts with ductile torque are used to secure the cylinder head to ensure good axial tension.

Cylinder block

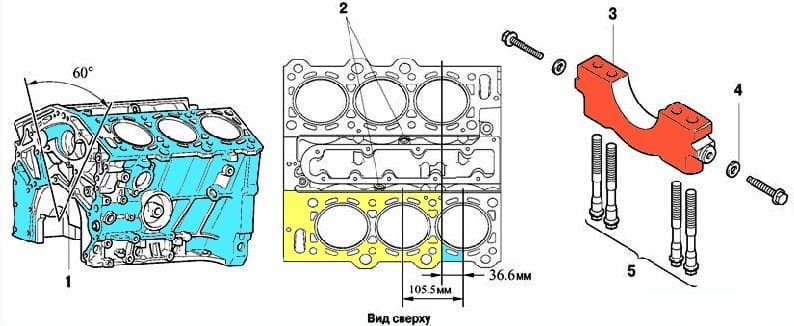

The cylinder block has a 60° camber angle, 36.6 mm (1.44 in) bank offset, and 105.5 mm (4.15 in) cylinder spacing for a compact design.

The cylinder block is made of lightweight aluminum alloy.

Thin-walled cast iron cylinder liners are fitted with an interference fit for added durability.

Cylinder liners are also thin-walled, so boring is not possible.

To ensure the compactness of the engine, the coolant pump chamber and the pump inlet are located in the collapse of the cylinder block.

The lugs of the knock sensors are located in two places in the collapse of the cylinder block.

The crankshaft bearing caps are attached with four bolts with a tightening torque in the plastic zone for each crankshaft main journal.

In addition, each cover is tightened with bolts in the transverse direction to increase the reliability of its fastening.

Piston

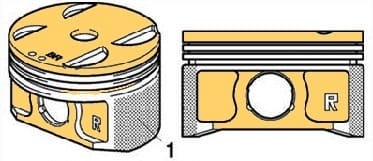

The piston is made of aluminum alloy and the skirt area is made compact and lightweight.

The piston skirt is coated with a polymer to reduce friction losses.

Piston pins - floating type.

The pistons of the right and left cylinder banks are different.

Crank

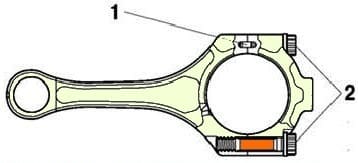

Cranks (fig. 6) are made of high strength steel to reduce weight.

Connecting rod bearings are coated aluminum.

Conrod bolts are used with tightening torque in the plastic zone.

Mating surfaces of the connecting rod and cap are provided with dowel pin holes to minimize shifting of the connecting rod caps during assembly.

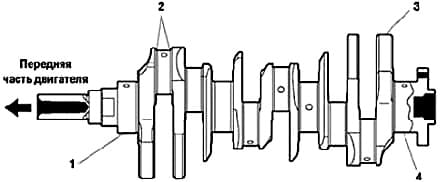

Crankshaft

Crankshaft (fig. 7) forged steel, has four main journals and nine counterweights.

The fillets of all crankshaft journals are knurled to ensure proper strength.

The bearings of the first and fourth main journals of the crankshaft are wider to reduce noise and vibrations, the bearings of the second and third main journals of the crankshaft are made narrower.

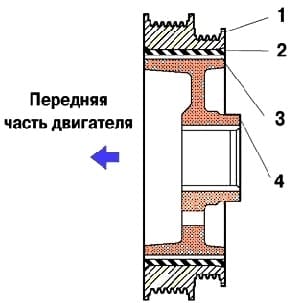

Crankshaft pulley

The crankshaft pulley bushing (fig. 8) is made of aluminum to reduce weight and vibration.

The rubber hardness of the vibration damper has been optimized to reduce noise.

Model - New

Number and arrangement of cylinders 6-cylinder, V-shaped

Timing mechanism - 24-valve with two overhead camshafts in the cylinder head, driven by a toothed belt

Combustion chamber - wedge type

Headers - cross flow

Fuel system - EFI

Displacement cm3 (inc) 2995(182.8)

Bore x Stroke mm (in) - 87.5 x 83.0(3.44 x 3.27)

Compression ratio - 10.5:1

Moment of valve opening or closing:

Inlet:

- - opening 4º BTDC

- - closing 44° after BDC

Graduation:

- - opening 46° to BDC

- - closing 2º after TDC

Cylinder order 1-2-3-4-5-6

Research octane rating of 95 or higher

Dry weight kg (lb) 158(348) 155(342)

Oil class - APISJ, SL, EU or or ILSAC

The design of this engine has been optimized to improve performance, fuel efficiency and reduce harmful emissions in the exhaust gases, and has the following features:

- - the engine is equipped with a PS starter with integrated planetary gear;

- – meets the requirements of European STEP III standards;

- - Equipped with ETCS-i Intelligent Throttle Control.

- - equipped with an air intake control system.

Distinctive features of the 1MZ-FE model engine

The characteristics of 1MZ-FE engines listed below are ensured by using the elements and systems indicated in the table.

|

Item/System |

1 |

2 |

3 |

4 |

5 |

New |

|---|---|---|---|---|---|---|

|

ETCS-i |

+ |

|

|

|

|

+ |

|

Aluminum alloy cylinder block |

|

|

+ |

|

|

+ |

|

Conical piston heads with displacer |

+ |

|

|

|

+ |

+ |

|

Direct Ignition System (DIS) |

+ |

|

|

+ |

+ |

+ |

|

For connecting fuel supply hose to petrol lines using quick connectors |

|

|

|

+ |

|

+ |

|

12-port fuel injectors high fuel atomization |

+ |

|

|

|

+ |

+ |

|

Iridium coated spark plug electrodes |

+ |

|

|

+ |

|

+ |

|

ACIS is used (air intake control system) |

+ |

|

|

|

|

+ |

|

Equipped with Air Intake Control |

+ |

+ |

|

|

|

+ |

|

Uses EGR system |

|

|

|

|

+ |

+ |

|

Two-level control system exhaust outlet |

+ |

+ |

|

|

|

+ |

|

Precise control provided by application exhaust oxygen concentration sensor |

|

|

|

|

+ |

+ |

|

Integrated planetary gear starter |

|

|

+ |

|

|

+ |

High efficiency and fuel efficiency.

Low noise and vibration.

Low weight and compact design.

Good operational reliability.

Minor outliers.