The ZMZ-409.10 engine complies with Euro3 toxicity standards.

Motors are manufactured in U2 climatic version, designed for operation in moderate climates at ambient temperatures from minus 45°C to plus 40°C and relative air humidity up to 100% at a temperature of plus 25°C.

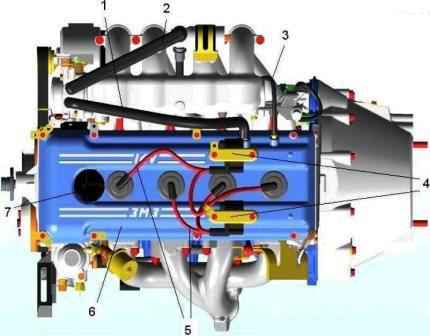

Top view of the ZMZ-409.10 engine

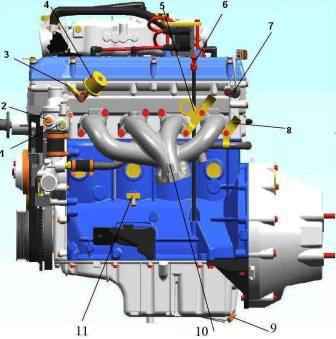

Left side of the ZMZ-409.10 engine

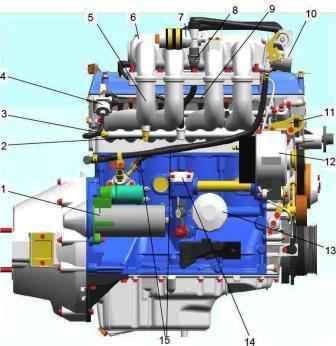

Right side of the ZMZ-409.10 engine

Front view of the engine ZMZ-409.10

Technical characteristics of the engine and its systems

Gasoline engine, 4-cylinder, 4-stroke, in-line, with a complex microprocessor control system for fuel injection, ignition and air intake

Cylinder diameter and piston stroke, mm 95.5 x 94

Cylinder displacement, cm3 2693

Compression ratio 9.0

Cylinder order 1-3-4-2

The direction of rotation of the crankshaft (on the pulley side) is right-hand

Rated power at a speed of 4500±50 min-1 gross according to GOST 14846, kW (hp) - 105 (142.8)

Maximum torque at a speed of 3900±200 min-1 gross according to GOST 14846, Nm (kgcm) 230.0 (23.5)

Power system - Distributed fuel injection by electromagnetic injectors into the intake pipe

Minimum specific fuel consumption, g/kWh (g/l.sch) 265.2 (195)

Oil consumption for waste, % of fuel consumption 0.3

Weight of unfilled engine with clutch, kg 190

Air filter - With dry replaceable filter element (installed on the car)

Ventilation system - Closed, forced, operating due to vacuum in the intake pipe

Lubrication system - Combined, with automatic oil temperature control

Oil filter - Full-flow, non-separable, fine cleaning 2105С-1012005-NK-2

Oil pressure indicator sensor - MM-358

Oil pressure alarm sensor - 30.3829

Cooling system - liquid, closed, with forced circulation of liquid

Thermostat - two-valve, with the opening temperature of the main valve 82±2˚ C TS 107-05 or TP2-01 or TA107-05

Electronic control system - Controls air supply, distributed fuel injection by electromagnetic injectors into the intake pipe and ignition

Spark plugs - DR17YC/A or A14DVR

Ignition coils 406.3705

Electrical equipment - DC, single-wire, negative terminals of sources and consumers are connected to the motor frame

Rated voltage, V 12

Generator - with built-in rectifier unit and voltage regulator 9422.3701 or 2502.3771

Starter with remote solenoid switch 6012.3708 or 405.3708000 (AZE2154 12V1,9 kWz9 11.131.262)

Coolant overheat alarm sensor - thermistor type ТМ111-02

Clutch - dry, single plate, with diaphragm pressure spring

Pressure in the lubrication system on a warm engine at the installation site of the emergency oil pressure sensor at an idle speed of 850±50 min-1, kPa (kgf/cm2), at least 98 (1.0)

Gap between electrodes of spark plugs, mm 0.7-0.85

Coolant operating temperature, °C 80-90

Minimum idle speed, min-1 850±50

Increased crankshaft speed, min-1 3150±50