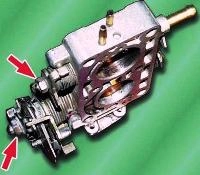

For lapping the valves, it is most convenient to use a special mechanical device (reversible drill). In addition, ready-made manual valve holders are available

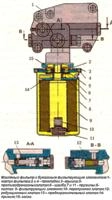

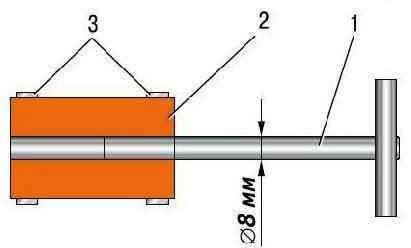

If they are not available, you can use a device made according to the drawing (Fig. 1).

In addition, you will need: lapping paste, kerosene, a weak spring, passing through the valve seat hole along the outer diameter.

Clean the valve from carbon deposits.

Apply a continuous, thin layer of lapping paste to the valve bevel.

Place a pre-selected spring on the valve stem and insert the valve into the guide sleeve from the side of the combustion chamber, lubricating the valve stem with a layer of graphite grease.

Graphite grease prevents the guide bushing from getting abrasive from the lapping paste into its holes and facilitates the rotation of the valve during lapping.

Put a valve lapping tool (or a rubber tube to connect the valve to the reversible drill) on the valve stem.

Turning on the drill at the minimum speed (in reverse mode) or rotating the device (in the case of manual lapping) alternately in both directions by half a turn, lap the valve, periodically pressing it against the seat, then loosening the pressing force.

An external sign of satisfactory lapping is a solid matte gray color of the valve face and valve seat in the block head

After lapping, thoroughly wipe the valve and seat with a clean cloth and rinse to remove any remaining lapping paste.

Check the tightness of the valve by installing it with springs and crackers in the head.

Then put the head with the combustion chambers up, plug the spark plug hole and pour kerosene into the combustion chamber.

If kerosene does not seep into the channel of the block head within 3 minutes, the valve is tight.