The D-245 diesel engine and its modifications are a 4-stroke piston four-cylinder internal combustion engine with an in-line vertical arrangement of cylinders, diesel fuel direct injection and compression ignition.

The main assembly units of a diesel engine are: cylinder block, cylinder head, pistons, connecting rods, crankshaft and flywheel.

To ensure high technical and economic performance of the diesel engine, a turbocharger with intercooling of the charge air was used in the intake system.

The use of a turbocharger with adjustable boost pressure in the boost device makes it possible to have improved throttle response on a diesel engine, provided by increased torque values at low crankshaft speeds.

The cylinder block is the main body part of the diesel engine and is a rigid cast iron casting.

There are four removable sleeves made of special cast iron in the vertical bores of the block.

The sleeve is installed in the cylinder block along two centering belts: upper and lower.

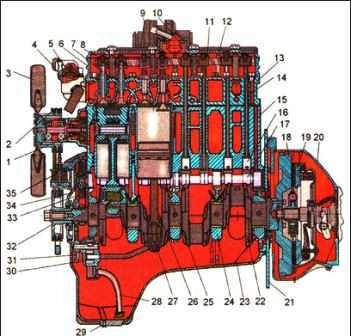

Longitudinal section of a diesel engine: 1 - liquid pump of the cooling system; 2 - drive belt for the generator and the liquid pump; 3 - fan; 4 - thermostat housing cover; 5 - thermostat; 6 - cylinder head cover; 7 - inlet valve; 8 - exhaust valve; 9 - turbocharger; 10 - crankcase ventilation valve; 11 - rocker; 12 - cap; 13 - cylinder head; 14 - pusher rod; 15 - cylinder block: 16 - pusher; 17 - camshaft; 18 - flywheel; 19 - clutch; 20 - flywheel housing; 21 - back sheet; 22 - crankshaft; 23 - oil sump; 24 - crankshaft bearing cap; 25 - piston; 26 - connecting rod; 27 - connecting rod cover; 28 - oil receiver pipe; 29 - drain plug; 30 - oil pump; 31 - oil pump drive gear: 32 - crankshaft pulley; 33 - camshaft drive gear; 34 - gear cover; 35 - support

In the upper belt, the sleeve is fixed with a shoulder, in the lower zone it is sealed with two rubber rings placed in the grooves of the cylinder block.

Coolant circulates between the walls of the cylinder block and the liners.

The end walls and transverse partitions of the cylinder block in the lower part have tides designed to form crankshaft bearings. Covers are installed on these tides.

The bosses, together with the covers, form beds for the main bearings.

Beds under the liners of main bearings are bored from one installation in assembly with main bearing caps, so it is impossible to interchange the caps.

The cylinder block has a longitudinal oil channel, from which oil flows through the transverse channels to the main bearings of the crankshaft and camshaft bearings.

The design of the diesel cylinder block provides for five camshaft bearings.

At the top of the second and fourth crankshaft bearings, nozzles are installed, which serve to cool the pistons with an oil jet.

On the outer surfaces of the cylinder block there are machined mating surfaces for attaching an oil filter, a water pump, coarse and fine fuel filters, a distribution board and a rear sheet.

The cylinder head is a cast iron casting, in the internal cavities of which there are inlet and outlet channels closed by valves.

Inlet channels - with a screw profile.

To ensure heat dissipation, the cylinder head has internal cavities in which coolant circulates.

The cylinder head has valve seat inserts made of a heat-resistant and wear-resistant alloy.

Racks, a rocker shaft with rocker arms, a head cover, an intake manifold and a cover cap that closes the valve mechanism are installed on top of the cylinder head.

On the left side (fuel pump side), four injectors are installed in the head, and an exhaust manifold is attached to the head on the right side.

To seal the connector between the cylinder head and the cylinder block, a gasket made of asbestos-free fabric reinforced with perforated steel sheet is installed.

The holes in the gasket for the cylinder liners are lined with sheet steel.

When assembling the diesel engine at the factory, the cylinder holes of the gasket are additionally edged with fluoroplastic split rings.

Crank mechanism

The main parts of the crank mechanism are: crankshaft, pistons with piston rings and pins, connecting rods, main and connecting rod bearings, flywheel.

Crankshaft - steel, has five main and four connecting rod journals.

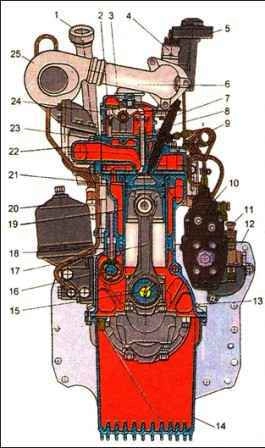

Diesel cross section: 1 - oil filler neck; 2 - cap; 3 - rocker; 4 - electric torch device (EFD); 5 - EFU tank; 6 - branch pipe; 7 - nozzle; 8 - valve; 9 - high pressure fuel pipe; 10 - high pressure fuel pump (TNVD); 11 - fuel pump; 12 - back sheet; 13 - cylinder block; 14 - Oil sump; 15 - crankshaft; 16 - camshaft; 17 connecting rod; 18 - pusher; 19 - sleeve of the cylinder block; 20 - centrifugal oil filter; 21 - piston

The axial force of the crankshaft is perceived by four bimetallic semi-rings or aluminum alloy semi-rings installed in the bores of the cylinder block and the fifth main bearing cap.

To reduce the load on the main bearings from inertia forces, counterweights are installed on the first, fourth, fifth and eighth cheeks of the crankshaft.

Front and rear, the crankshaft is sealed with cuffs.

The timing gear (crankshaft gear), oil pump drive gear, water pump and alternator drive pulley are installed on the front end of the shaft.

A flywheel is attached to the rear flange of the shaft.

The piston is made of aluminum alloy.

A combustion chamber is made in the bottom of the piston.

The combustion chamber is offset relative to the piston axis.

In the upper part, the piston has three grooves - compression rings are installed in the first two, and an oil scraper ring in the third.

An insert made of special cast iron is cast under the groove of the upper compression ring.

In the piston bosses, holes for the piston pin are bored out.

Piston rings are made of cast iron.

The upper compression ring is made of high-strength cast iron and has the shape of an isosceles trapezoid in cross section.

The second compression ring is tapered. On the end surface near the lock, the compression rings are marked "Top" ("TOR").

Box type oil scraper with spring expander.

Piston pin - hollow, made of chromium-nickel steel.

The axial movement of the pin in the piston bosses is limited by the circlips.

Connecting rod - steel, I-section.

A bushing is pressed into its upper head.

There are holes in the top end of the connecting rod and bushing to lubricate the piston pin.

The boring of the bed in the lower head of the connecting rod for liners is assembled with a cover.

Therefore, it is not allowed to change the connecting rod caps.

The connecting rod and cap have the same numbers stamped on their surfaces.

In addition, the connecting rods have weight groups according to the mass of the upper and lower heads.

The designation of the mass group is applied on the end surface of the upper head of the connecting rod.

The connecting rods of the same group must be installed on a diesel engine.

Inserts of the main and connecting rod bearings of the crankshaft are made of a bimetallic strip.

Diesels use main and connecting rod bearing shells in two sizes in accordance with the rating of the crankshaft journals.

Four repair sizes of liners are also provided for diesel repair.

The flywheel is made of cast iron and bolted to the crankshaft flange.

A steel ring gear is pressed onto the flywheel.

The camshaft consists of a camshaft, intake and exhaust valves, as well as parts for their installation and drive: pushers, rods, rocker arms, adjusting screws with nuts, plates with crackers, springs, racks and axles rocker.

Camshaft - five-bearing, driven from the crankshaft through distribution gears.

The camshaft bearings are five bushings pressed into the bores of the block.

The front bushing (on the fan side) is made of aluminum alloy and has a stop collar that holds the camshaft from axial movement, the rest of the bushings are made of special cast iron.

Pushers - steel. The working surface of the pusher plate is hardfaced with chilled cast iron and has a spherical surface with a large radius (750 mm).

As a result of the fact that the camshaft cams are made with a slight inclination, the pushers perform a rotational movement during operation.

The push rods are made of steel bar.

The spherical part inside the pusher and the rod cup are hardened.

Valve rockers - steel, swing on about si mounted on four racks.

Extreme posts - increased rigidity.

The axis of the rocker arms is hollow, it has eight radial holes for supplying oil to the rocker arms.

The movement of the rocker arms along the axis is limited by spacer springs.

Inlet and outlet valves are made of heat-resistant steel.

They move in guide bushings pressed into the cylinder head.

Each valve closes under the action of two springs: external and internal, which act on the valve through a plate and crackers.

Sealing collars installed on the valve guides prevent oil from entering the diesel cylinders and the exhaust manifold through the gaps between the valve stems and the guides.

Technical characteristics of diesel D-245.12

Diesel type - Four-stroke turbocharged diesel

Method of mixture formation - Direct fuel injection

Number of cylinders - 4

Cylinder arrangement - Inline, vertical

Cylinder order 1 - 3 - 4 - 2

cylinder diameter 110 mm

125 mm stroke

Cylinder displacement 4.75 l

Crankshaft rotation direction - Right

Compression ratio (calculated) 15.1

Rated power kW (hp) - 80 (108.8)

Rated speed, min-1 - 2400

Maximum torque Nm - 350

Rotational speed at maximum torque, min-1 - 1300-1700

Minimum stable idle speed, min-1, no more than 800±50

Specific fuel consumption according to external velocity characteristic g/kWh:

- -minimum - 218

- - At rated power - 245

Hourly fuel consumption at rated power, kg/h 19.6

Hourly fuel consumption at minimum stable idle speed, kg/h, no more than 1.5

Nominal setting fuel injection advance angle, deg. up to TDC 19 ±1

Total oil consumption (including replacement) as a percentage of fuel consumption, no more than 1.3

Oil consumption for waste according to GOST 18509-88 as a percentage of fuel consumption, no more than 0.5

Oil pressure in the main oil line at nominal diesel operation, MPa 0.25…0.35

Weight of dry diesel 500 kg

Overall dimensions mm -1011.5 x 702.0 x 1080.5