Oil pump - gear, with internal gears and pressure reducing valve

The drive is carried out from the toe of the crankshaft

The drive gear (smaller diameter) is mounted on two flats on the front end of the crankshaft.

The maximum diameter of the socket for the driven (large) gear during wear should not exceed 75.10 mm, the minimum width of the segment on the housing separating the drive and driven gears is 3.40 mm.

The axial clearance should not exceed 0.12 mm for the drive gear and 0.15 mm for the driven gear.

Usually, the pump is removed when repairing the engine, less often when the pump performance is poor.

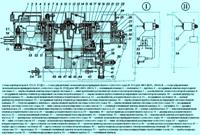

Removing the engine oil pump

Remove the crankshaft position sensor, for this:

- - using a 10 key, unscrew the sensor mounting bolt

- - remove the sensor from the hole in the tide on the oil pump housing

- - Remove the alternator drive pulley (see "Replacing the timing belt")

- - Remove the oil pan

- - Remove the oil receiver (see "Removing and installing the oil receiver")

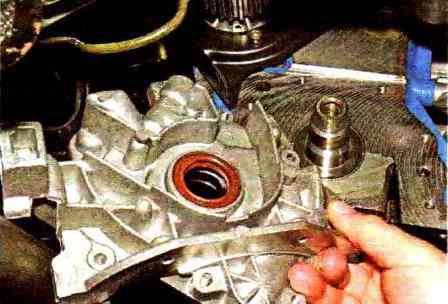

With a head of 10, we unscrew the six bolts securing the oil pump to the cylinder block.

Pry off the pump housing with a screwdriver

Remove the oil pump

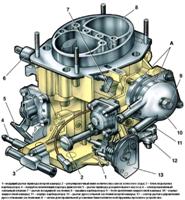

Oil pump disassembly

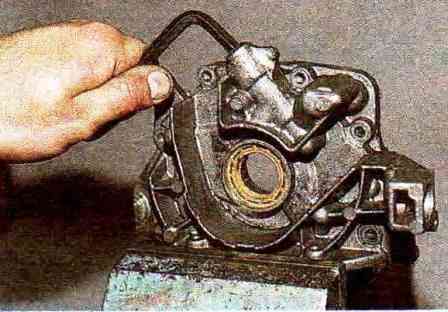

Remove the oil pump seal

Clamp the pump in a vise with soft metal jaws.

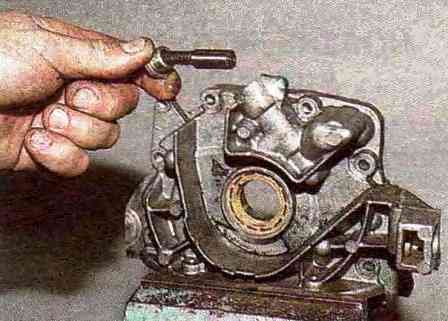

Using an 8 hexagon, unscrew the plug of the pressure reducing valve (sealed with an aluminum ring).

Remove the pressure reducing valve spring and piston

Using a 5 hexagon, we unscrew the six screws securing the cover to the pump housing.

Remove the pump cover and remove the driven and driving gears.

We wash the parts of the oil pump and check their technical condition - the diameter of the nest for the driven gear, the width of the segment on the housing, the axial clearances of the gears.

We assemble the pump in the reverse order, having previously lubricated the gears, the housing in the gear area and the pressure reducing valve piston with engine oil.

Set the gears with chamfers on the tops teeth inside the pump housing.

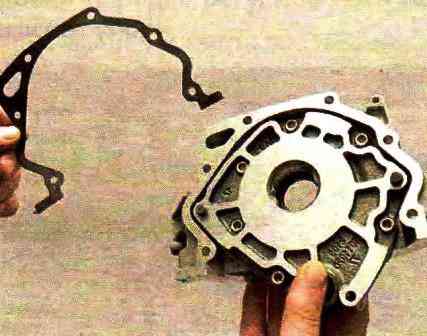

Before installation, we clean the mating surfaces of the pump housing and cylinder block from the remnants of the old gasket, dirt and oil.

Install the oil pump with a new gasket in reverse order.

When installing the pump, we combine the flats on the crankshaft with the protrusions in the hole of the pump drive gear.