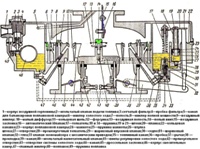

The oil pump is removed for replacement or repair when the pressure in the lubrication system drops below the permissible level, when the gears are noisy and the pressure reducing valve plunger is stuck

You will need: socket wrenches "for 12", "for 14", a hexagon "for 6", a screwdriver, a set of probes.

Drain the engine oil.

Remove the oil pan.

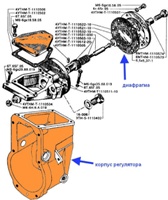

Remove the bolt of the additional oil pump mounting bracket.

Remove the two bolts securing the pump to the cylinder block and remove the pump with oil receiver assembly.

Remove the screen from the oil receiver by bending its edges.

Remove the three bolts.

Disconnect the housing and the oil receiver of the pump.

Remove the intermediate plate...

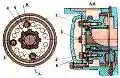

Remove the driven gear and drive gear with roller from the housing.

If you need to remove the drive gear from the roller, knock out the pin

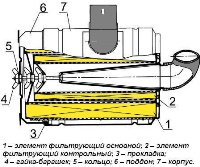

To disassemble the pressure reducing valve, remove the cotter pin.

Reducing valve spring is preloaded.

Remove the cotter pin very carefully to avoid injury and loss of shims.

Sequentially remove the adjusting washers from the oil receiver ...

Remove the spring

Remove the pressure reducing valve plug

Wash the pump parts with gasoline and blow with compressed air.

If there is wear from the gears on the intermediate plate, the plate must be sanded so that no traces of wear remain.

Examine the hull.

If it is badly worn, replace the pump.

Check for ease of rotation of the gears in the pump housing.

They should rotate freely.

Check for ease of movement of the pressure reducing valve plug in the body.

It should move freely.

Clean off dirt and rinse the oil receiver screen with white spirit.

If the mesh cannot be cleaned or is damaged, replace it.

Inspect the reduction gear spring lapan.

If cracks are visible on it, replace the spring.

If possible, check the elasticity of the spring.

The length of the spring in the free state should be 50 mm, to compress the spring to a length of 40 mm, a force of 43.5–48.5 N (4.35–4.85 kgf) must be applied.

If the spring does not meet at least one of these requirements, replace it.

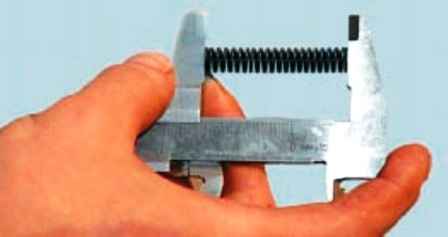

Measure with a flat feeler gauge, applying a ruler or caliper to the surface, the gap between the ends of the gears and the surface of the housing.

The gap should be 0.040-0.140 mm.

Measure the gap between the outer diameters of the gears and the housing with a flat feeler gauge.

The gap should be 0.120-0.215 mm.

If the end and radial clearances exceed the specified values, replace the housing.

Measure the gap between the gear teeth with a feeler gauge. The gap should be 0.15 mm.

If the clearance is greater than the specified value, replace the gears.

Replace worn or damaged parts.

Observing maximum cleanliness during assembly, assemble the pump in the reverse order of disassembly

Install the parts in the reverse order of removal. Fill the engine with oil.