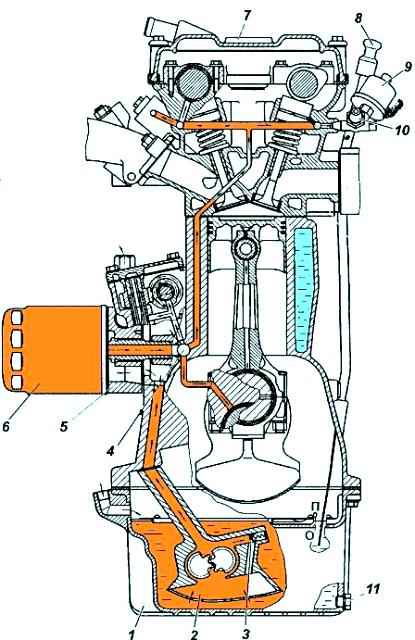

Combined engine lubrication system: oil is supplied to the rubbing surfaces of parts under pressure and splashing

The lubrication system consists of an oil crankcase, an oil pump with a suction pipe and a pressure reducing valve, an oil pump drive, oil channels in the block, block head and crankshaft, a full-flow oil filter, an oil level indicator, an oil filler cap, oil pressure sensors.

The oil level indicator is marked "P" and "0" respectively, the upper and lower levels.

The oil level must be between these marks.

Oil circulation is as follows.

The pump sucks oil from the crankcase and brings it through the channel in the block to the full-flow filter.

After the filter, the oil enters the main oil line and through the channels in the block lubricates the main and connecting rod bearings of the crankshaft, piston pins, bearings of the camshafts, the intermediate shaft and the oil pump drive shaft, as well as the helical gears of the oil pump drive.

From the upper bearing of the oil pump drive roller, oil is supplied through the transverse drillings and the inner cavity of the roller to lubricate the lower roller bearing and the bearing surface of the driven gear of the drive.

The oil pump drive gears are lubricated by a jet of oil through a hole in the main oil line.

To cool the piston, oil is sprayed onto the piston head through a hole in the upper head of the connecting rod.

From the main oil line through a channel in the block, oil enters the cylinder head, lubricates the camshaft bearings and is supplied to the hydraulic tensioner of the chain of the second stage of the camshaft drive, to the hydraulic pushers and oil pressure sensors.

Following from the gaps and flowing into the crankcase at the front of the cylinder head, oil lubricates the chains, tensioner levers and camshaft drive sprockets.

Oil pressure is monitored by a pressure sensor and a pointer in the instrument cluster.

In addition, the system is equipped with a sensor and an emergency oil pressure drop warning light.

It lights up when the pressure in the system reaches 40–80 kPa (0.4–0.8 kgf/cm 2).

The pressure sensors are screwed into a fitting installed in the oil channel of the cylinder head.

The single-section gear-type oil pump is installed inside the oil sump and is driven from the intermediate shaft by a pair of helical gears.

The pump body and suction pipe are made of aluminum alloy, the baffle is made of cast iron, the gears are made of sintered metal.

An oil cooler with a safety valve is included in the system to cool the oil, and a full-flow oil filter is used to clean the oil.