Removing and installing water pump

The water pump is removed for access to other parts, as well as for its repair or replacement if noise occurs during operation, the level of which exceeds the usual level and which appears when a large radial play of the pump shaft is formed

Disassembling the pump is a rather laborious job, so if a malfunction occurs, we recommend replacing the pump assembly.

You will need: a “12” wrench, a “6” hex key, a flat-blade screwdriver, a mounting spatula.

The work on removing and installing the water pump is shown with the radiator of the engine cooling system removed.

Drain the engine cooling system.

Remove the power steering pump from the bracket.

Remove the fan drive viscous coupling.

Remove the alternator and water pump drive belt.

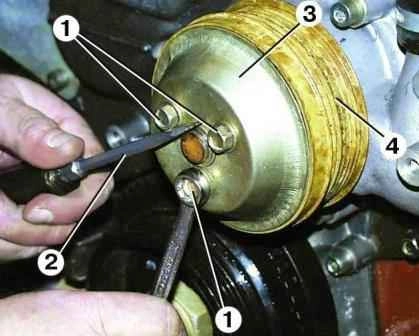

Having fixed the pulley from turning, unscrew the three bolts of its fastening

Remove the pulley deflector and pulley.

Remove the two bolts securing the power steering pump bracket from above

Remove one bolt from the bottom

We move the bracket with the power steering pump to the side

Loosen thermostat hose clamps and coolant pickup hose clamps

Remove the other two front bolts

Remove one bolt from the back

Then remove the water pump

Clean the mating surface of the old gasket

Install the water pump and all removed parts in reverse order.

Do not forget to apply sealant to the mating surfaces of the water pump and cylinder block.

Fill in coolant and remove air pockets from the cooling system.

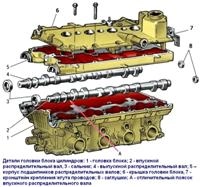

Disassembly

The impeller is molded from plastic, but has a metal hub, in which a thread for a puller is cut.

Remove pump impeller 1 using a puller

Compress the hub 1 of the pump pulley with a puller.

Unscrew retainer 2 of the bearing and press the bearing with the pump shaft towards the pulley

Press out the oil seal of pump 1.

Rinse and clean the pump parts from deposits.

Troubleshooting

The bearing on the pump shaft must rotate freely without binding, otherwise replace the bearing with shaft assembly.

If a large play is felt in the bearing, traces of lubricant leakage from under the protective rings are noticeable or the balls roll when the bearing rotates, it must be replaced as an assembly with the roller.

Inspect the impeller. If it has cracks, chips, etc., replace it.

Inspect the gland. If it has tears, cracks, the rubber has lost its elasticity, the compression spring is broken, replace the oil seal.

Assembly

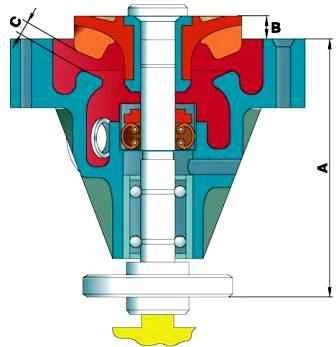

- A = (117.5±0.2) mm (motors mod. 402 and 4021);

- B = 0 / 0.2 mm (motors mod. 402 and 4021);

- C = 0.9 / 1.3 mm (motor mod. 409)

The pump is assembled in the reverse order of disassembly.

When assembling the pump, inspect the gaskets, if they have tears or the gaskets are heavily compressed, they must be replaced.

When pressing the impeller and hub, the emphasis should be on the pump shaft.

When assembling the pump, keep the dimensions shown in the figure.

After screwing in the bearing retainer, you need to punch out the edges of the hole so that part of the metal enters the slot of the retainer to prevent self-loosening.