We dismantled the engine in the article - Dismantling the VAZ-21126 engine

Engine parts were detected in the article - Defection of engine parts VAZ-21126

You will need: a torque wrench, a hammer (preferably with a soft metal or polyurethane head), a device for installing pistons in cylinders, the same wrenches as for disassembling the engine, a screwdriver, a mounting spatula.

Clean the carbon deposits from the edges of the cylinder block beds.

Clean the deposits from the oil grooves in the beds.

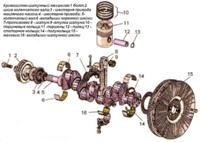

Install the main bearing shells in the bed of the cylinder block in accordance with the marks made during disassembly.

When installing the liners, their locking antennae must enter the grooves of the beds.

Lubricate the liners with engine oil.

After installing the liners in the bed, their ends protrude slightly, therefore, for the correct orientation of the liners, when final tightening the bearing cap bolts, make sure that the protrusion of both ends is the same.

Install the crankshaft into the cylinder block.

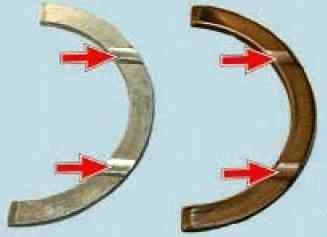

Lubricate the thrust half rings with engine oil.

Pay attention to the grooves of the half-rings: these sides of the half-rings should be installed to the cheeks of the crankshaft.

Install a steel-aluminum semi-ring (white) on the front side of the middle bed (on the camshaft drive side) and a cermet (yellow) on the other side of the bed.

Rotate the half rings so that their ends are flush with the ends of the bed.

Insert the liners into the main bearing caps according to the marks made during disassembly.

In this case, the locking antennae of the liners should enter the grooves of the covers.

Lubricate the liners with engine oil.

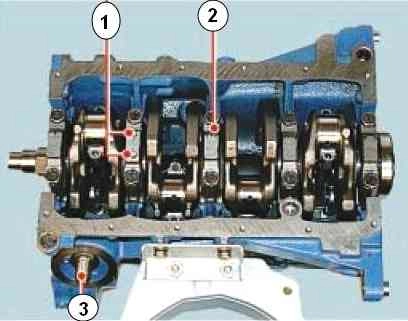

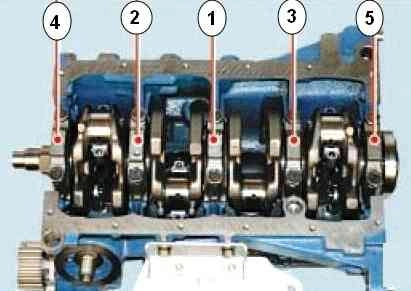

Install the covers according to the marks. The covers are marked (notches) in accordance with the cylinder number.

The exception is the fifth lid, which has two marks, just like the second one.

On the second cover there are two threaded holes 1 for the oil receiver mounting bolts.

In this case, the cylinder numbers are counted from the camshaft drive side, and the covers are installed with marks 2 in the opposite direction from the oil filter fitting 3.

Use a soft-faced hammer made of brass, lead, or polyurethane to install the crankshaft main bearing caps.

It is forbidden to install the covers by tightening the fasteners, as this will damage the seating surfaces of the covers and the cylinder block.

Lubricate the threads and ends of the cap bolt heads with engine oil.

Install the bolts and tighten them to the required torque in the following order: Tighten the tr bolts first the third cover, then the second and fourth, then the first and fifth.

After tightening the bolts, turn the crankshaft 2-3 turns - it should rotate easily, without jamming.

For ease of installation, apply a light coat of grease to the oil pump gasket and "glue" it to the block. Remove excess grease.

Install the oil pump and tighten its mounting bolts.

For ease of installation, lightly grease the rear oil seal retainer gasket and "glue" it to the block. Remove excess grease.

Install the rear oil seal holder and tighten its mounting bolts.

Insert the connecting rod into the piston in accordance with the previously made marks so that the number of the mark on the connecting rod is facing the front of the piston (the arrow stamped on top of the piston bottom is directed in this direction)

Lubricate the piston pin with engine oil and insert the pin into the piston and connecting rod.

Install retaining rings on both sides of the pin.

In this case, pay attention to the fact that the rings must be clearly installed in the piston grooves.

A ring that is not clearly fixed in the piston groove will pop out of it when the engine is running and cause accidental damage.

Install the oil scraper ring expander on the piston.

Install the piston rings.

It is recommended to do this with a special puller.

If it is not there, install the rings on the piston, carefully spreading the locks of the rings.

The order of installation of the rings: the oil scraper ring is installed first (the lock of the ring must be on the opposite side of the expansion spring lock), then the lower compression ring, the last - the upper compression.

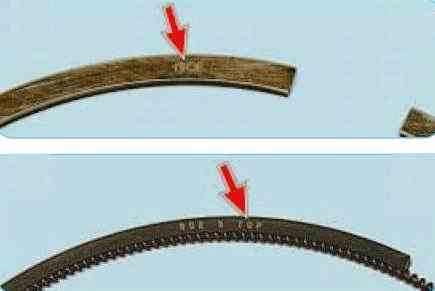

Please note that the rings may be embossed with "GOE" or "TOP".

Rings should be installed with this inscription up (towards the piston crown).

Rotate the rings in the piston grooves to make sure they turn easily.

If any ring does not turn or sticks, it must be replaced.

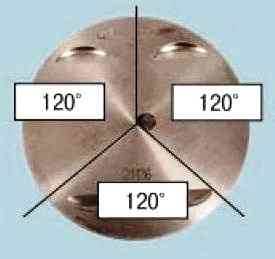

Turn the rings on the piston so that their locks are at an angle of 120° to each other.

Thoroughly wipe the crankshaft journals with a clean cloth.

Thoroughly wipe the cylinder mirrors with a clean cloth and lubricate them with engine oil.

Insert the liner into the connecting rod in accordance with the marks made earlier so that the antennae of the liner enters the groove in the connecting rod.

After that, lubricate the liner and piston with engine oil.

Put a special mandrel on the piston to compress the piston rings and carefully lower the connecting rod into the cylinder.

It is recommended to pre-turn the crankshaft so that its connecting rod journal, on which the connecting rod and piston group is mounted, is installed at BDC.

The arrow on the piston crown must point towards the front of the engine (camshaft drive side).

Press the mandrel firmly against the block and use the handle of the hammer to push the piston into the cylinder.

If the mandrel does not fit snugly against the cylinder block, piston rings can be broken.

Install the connecting rod end onto the crankshaft journalla

Insert the liner into the connecting rod cap in accordance with the previously made marks so that the liner antenna fits into the groove in the cap.

After that, lubricate the liner with engine oil.

Install the connecting rod cap.

The connecting rod markings on the cap and bottom end of the connecting rod must be on the same side.

Install the cover bolts and tighten to the correct torque. Install the rest of the pistons in the same way.

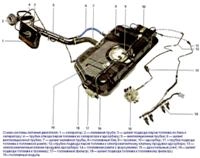

Install the oil receiver and tighten the three bolts of its fastening.

Apply an anaerobic threadlocker to the flywheel mounting bolts. Install the flywheel, lock plate and tighten the flywheel mounting bolts.

For ease of installation, apply a thin layer of grease to the surface of the block and "glue" the oil pan gasket to it.

Install the oil sump and tighten its bolts.

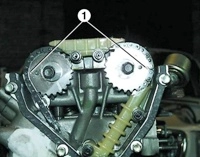

Reassemble the engine in reverse order.

The installation of the block head is described in the article "Replacing the cylinder head gasket", the camshaft drive belt - in the article "Replacing the timing belt and tension roller".