The VAZ-21126 engine is installed on different types of cars

Let's consider the removal of the cylinder head on the example of the Lada Priora car.

A sign of gasket damage is:

- - Coolant leak;

- - Emission of steam with gases through the exhaust pipe (white, thick smoke from the exhaust pipe);

- - Detection of an emulsion on the oil level dipstick, the appearance of an emulsion on the oil filler cap;

- - Intensive heating of the engine;

- - Coolant seething in the expansion tank.

The head gasket is single use, so the gasket must be replaced each time the head is removed.

Remove the decorative engine cover.

Set the piston of the 1st cylinder to the TDC position of the compression stroke.

Reduce the pressure in the fuel system if work is carried out immediately after a trip.

Disconnect the wire from the negative terminal of the battery.

Drain the coolant.

Remove the air filter.

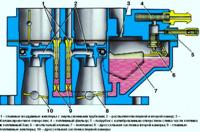

Disconnect from the throttle assembly the heating hoses, the small branch of the crankcase ventilation system, the adsorber purge, the air inlet hose, the throttle position sensor and idle speed control wiring harness blocks.

Remove the throttle assembly.

Disconnect the wiring harness connectors from the ignition coils. Remove the ignition coils and remove the spark plugs.

Disconnect the wiring harness connector from the emergency oil pressure drop sensor

Disconnect the wiring harness connector from the engine management coolant temperature sensor

Disconnect the wiring harness block from the phase sensor

Loosen the clamps and disconnect the five cooling system hoses from the thermostat pipes

Disconnect the wiring harness connector from the coolant temperature gauge sensor

Unscrew the nut fastening the tip of the "mass" wire with the key "13"

Remove the wire.

Unscrew the fuel hose union nut and disconnect it from the fuel pipe.

The tip of the fuel pipe is sealed with a rubber ring.

Don't lose it when disassembling.

Replace a heavily compressed or torn O-ring.

Remove the screw on the pressure plate of the fuel line-to-cylinder head bracket and remove the plate

Unscrew the fastening bolt with a key "10"

Disconnect the ground wire from the block head.

Remove the intake manifold.

Remove the head cover.

Unscrew the fastening bolts with a “5” hex wrench and remove the front protective cover of the timing belt

Remove the lid.

Using a 5" hexagon wrench, remove the bolts securing the lower front cover of the timing belt

Remove the lid.

Loosen the tension roller mounting bolt with the “15” wrench

Remove the timing belt

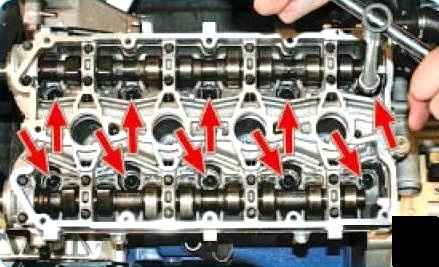

While holding the camshaft pulleys from turning, remove the bolts securing the pulleys

Remove the pulleys

Remove the keys from the grooves of the shaft shanks.

To keep the camshafts from turning when unscrewing the bolts for fastening the toothed pulleys of the camshafts, we recommend using the tool shown in the photo.

The intake and exhaust camshaft pulleys have the same fitting dimensions, but a disk is fixed on the intake camshaft pulley, which ensures the operation of the phase sensor.

Having unscrewed the fastening bolt with the “15” key, remove the tension roller

Note that there is a distance ring underneath the roller

Removing the mounting bolt with a 15 wrench, remove the support roller.

Unscrew the five bolts securing the rear protective cover of the timing belt with a “10” wrench.

Remove the lid.

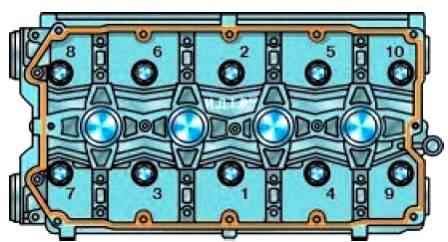

The order of tightening the cylinder head bolts

Unscrew the bolts securing the cylinder head to the cylinder block with a 10 hex wrench in the reverse order of tightening

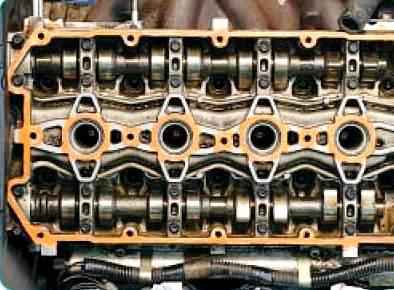

Remove the block head from the engine.

Do not drive a screwdriver or other tools between the head and cylinder block.

Removing the cylinder head is more convenient with an assistant, as it is quite heavy.

Remove the head gasket.

Cylinder head bolts stretch with repeated use.

Replace bolts that are longer than 98 mm (excluding head height).

Before installing the head of the block, lubricate the bolts with a thin layer of engine oil.

Clean the mating surfaces of the cylinder head and cylinder block (they must be dry and clean).

Remove the oil from the threaded holes in the block for the head bolts.

If the oil is not removed from the threaded holes for the head bolts, cracks may appear in the cylinder block when the bolts are tightened, since the oil does not compress.

Check the presence of two mounting bushings in the sockets of the extreme holes of the cylinder block for the head bolts.

If, when removing the head, the bushings remain in the head or come out of the sockets of the block, press them into the block until they stop

Install a new head gasket on the block.

Before installing the gasket, it is necessary to remove the oil from the mating surfaces of the block and its head.

The gasket must be clean and dry. It is not allowed to get oil on the surface of the gasket.

Install the head on the block, after making sure that the crankshaft and camshafts are in the TDC position (both valves of the 1st cylinder must be closed).

Tighten the block head bolts in the sequence shown in Fig. 35 in four steps:

- 1st - torque 20 Nm (2 kgf m);

- 2nd - torque 69.4–85.7 Nm (7.1–8.7 kgf m);

- 3rd - turn the bolts 90°;

- 4th - finally tighten the bolts 90°.

Install on the head removed parts and connect the hoses and wires to it in the reverse order of removal

Install the intake camshaft pulley with the disc that provides the phase sensor to the engine.

Install the exhaust camshaft pulley in the same way.

Adjust the tension of the timing belt and the alternator drive belt.

Before installing the cylinder head cover, apply sealant to the camshaft bearing housing. It is allowed to start the engine no earlier than after one hour.

Install the intake camshaft pulley with the disc that provides the phase sensor to the engine.

Install the exhaust camshaft pulley in the same way.

Adjust the tension of the timing belt and the alternator drive belt.

Before installing the cylinder head cover, apply sealant to the camshaft bearing housing. It is allowed to start the engine no earlier than 1 hour after applying the sealant.