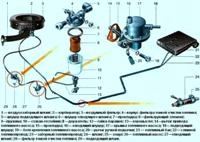

The power system consists of:

- - fuel tank;

- - coarse filter;

- - fuel fine filter;

- - booster pump;

- - injection pump pump;

- - injectors

Fuel from the tank, which has passed through a coarse fuel filter, is supplied under a pressure of 0.8-0.9 MPa by a fuel priming pump to the inlet fitting of the injection pump.

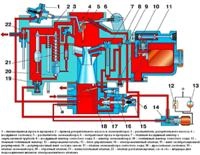

Under the influence of the created boost pressure, the protective valve opens access to fuel through the supply channel to the above-plunger spaces.

The incoming cam of the rotor moves the plunger upwards, while the inlet of the inlet channel is blocked and as the plunger further rises, the fuel is compressed in the above-plunger space of the injection pump.

Compressed fuel enters the corresponding injector in accordance with the diesel cycle.

Excess fuel is returned to the tank.

Injection pump characteristics

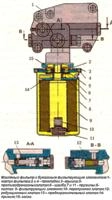

High pressure fuel pump model 4UTNI-T-1111005-50

Plunger diameter 9.0 mm

Plunger stroke 9.0 mm

Spacing between sections 32 mm

Dimensions (length, width, height), 398x171x284 mm

Weight, no more than 14.5 kg

Direction of rotation of the camshaft (drive side) - Right-hand

Pump section order 1-3-4-2

Angles of rotation of the camshaft (from the drive side), degrees 0-90-180-270

Ratio of camshaft speed to diesel crankshaft speed 1:2

Plunger stroke in the first section from the lower extreme position to the geometric start of injection - 3.3+ 0.05 mm

Discharge valve - Mushroom, feather

Lubrication system - circulation, oil, with oil supply under pressure from the diesel lubrication system

Fuel priming pump - Piston with manual fuel priming pump

Regulator - Centrifugal, all-mode, direct action with boost corrector

Supercharge corrector - Pneumatic

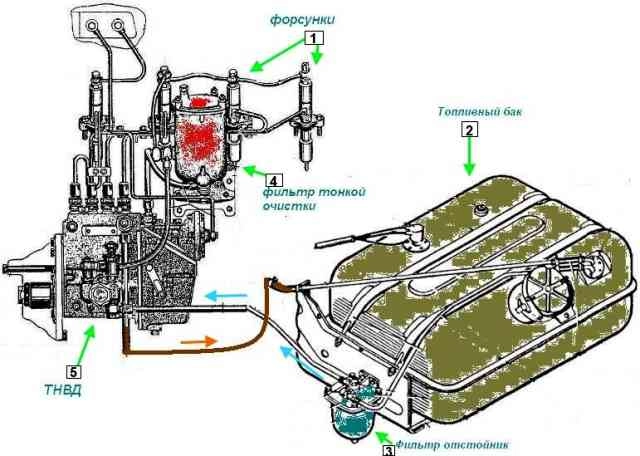

Nozzle - Mod. 17.1112010-01, closed type with hydraulically controlled needle lift, rod

Installed nozzle diameter - 22.5 mm

The method of adjusting the pressure of the start of fuel injection - Adjusting screw

Injection start pressure, MPa 17.5-18.2

Atomizer type mod. 145.1112110, fixed, multi-jet, five-hole

Nozzle weight - 0.75 kg