The litany system includes elements of the following subsystems:

- - fuel supply, including a fuel tank, an electric fuel pump, a fuel filter, a fuel pressure regulator, pipelines and a fuel rail with injectors;

- - air supply, including an air supply pipe, an air filter, a throttle assembly, an idle speed controller:

- - catching fuel vapors, including an adsorber and connecting pipelines.

The functional purpose of the supply system is to ensure the supply of the required amount of fuel to the engine in all operating modes.

The engines are equipped with an electronic engine management system with multiport fuel injection

In the multiport injection system, the functions of mixture formation and dosing of the air-fuel mixture supply to the engine cylinders are separated;

- - air is supplied by an air supply system consisting of a throttle assembly and an idle speed controller, and the amount of fuel required at each moment of engine operation is injected into the intake pipe by injectors.

This control method makes it possible to ensure the optimal composition of the combustible mixture at each particular moment of engine operation, which allows you to get maximum power with the lowest possible fuel consumption and low exhaust gas toxicity.

The fuel injection system (as well as the ignition system) is controlled by an electronic unit that continuously monitors the engine load, the vehicle speed, the thermal state of the engine, and the optimal combustion process in the engine cylinders using appropriate sensors.

The fuel vapor recovery system prevents fuel vapors from escaping into the atmosphere, which adversely affect the environment.

The system uses the method of vapor absorption by a carbon adsorber.

It is installed in the niche of the right front fender and is connected by pipelines to the fuel tank and intake pipe.

On the adsorber cover there is an adsorber purge solenoid valve, which switches the system operation modes by signals from the engine control unit.

Fuel vapors from the fuel tank are constantly discharged through the pipeline and accumulate in the adsorber filled with activated carbon (adsorbent).

When the engine is running, the adsorbent is regenerated (recovered) by purging the adsorber with fresh air entering the system under the action of vacuum transmitted through the pipeline from the inlet pipe to the adsorber cavity when the valve is opened.

The value of the valve opening, and hence the intensity of the purge of the adsorber, depends on the angle of rotation of the throttle valve and is determined by the vacuum. which occurs in the cavity of the intake pipe of a running engine.

Fuel vapors from the adsorber through the pipeline enter the engine intake pipe and burn in the cylinders.

Failures in the evaporative emission system can lead to unstable idling, engine shutdown, increased toxicity of exhaust gases and poor driving performance.

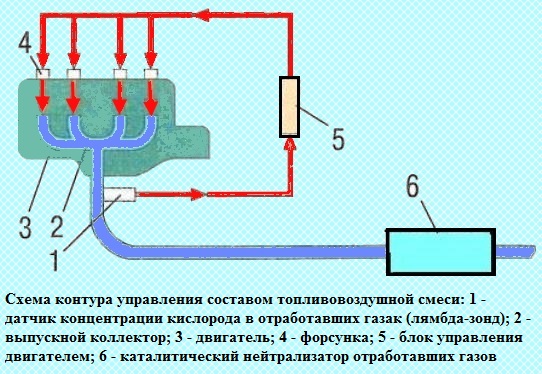

The main sensor for ensuring an optimal combustion process is the oxygen concentration sensor in the exhaust gases (lambda probe).

It is installed in the engine exhaust manifold and, together with the electronic unit and injectors, forms a circuit for adjusting the composition of the air-fuel mixture supplied to the engine (Fig. 1.)

Based on the sensor signals, the engine control unit determines the amount of unburned oxygen in the exhaust gases and, accordingly, evaluates the optimal composition of the air-fuel mixture entering the engine cylinders at any given time.

Having fixed the deviation of the composition from the optimal 1:14 (fuel and air, respectively), which ensures the most efficient operation of the exhaust gas catalytic converter, the control unit changes the composition of the mixture using injectors.

As a result, the air-fuel ratio control loop is closed,

Some vehicles have two oxygen sensors; one - in the exhaust manifold, the second - behind the catalytic converter.

The first sensor is control (based on its signal, the ECU corrects the fuel supply), and the second is diagnostic (based on its signal, the ECU evaluates the efficiency of the catalytic converter).