We remove the oil receiver when repairing the engine or when the oil receiver mesh is clogged, and the engine is starved of oil

When the engine is "starved" of oil, the emergency oil pressure lamp starts to burn.

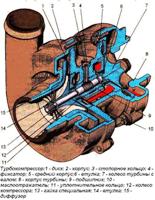

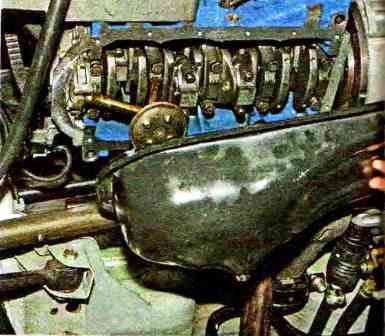

General view of the oil receiver in Figure 1

Drain the oil from the crankcase.

To do this, loosen the drain plug with a ring wrench or a 17 head.

We substitute a wide container for used oil with a volume of at least 4 liters under the hole and, having unscrewed the plug manually, drain the oil.

After wiping the cork, we wrap it with a torque of 35–45 Nm.

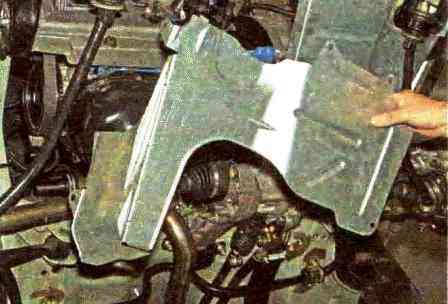

Remove the right mudguard of the power unit

Remove the bottom cover of the clutch housing.

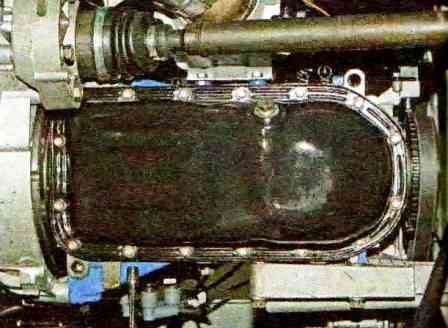

With a head of 10, we unscrew 16 bolts securing the oil pan

Removing the pallet

Remove the oil pan gasket

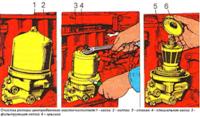

Using a 10 head with an extension, unscrew two bolts 1 fastening the oil receiver to the main bearing cap and bolt 2 fastening the oil receiver to the oil pump housing.

We remove the oil receiver pipe from the hole in the pump housing and remove the oil receiver.

The connection of the oil receiver pipe with the pump housing is sealed with a rubber ring

If the ring is cracked or has lost its elasticity, it must be replaced.

Before installing the oil receiver, we clean its mesh, rinse it with a solvent and blow it with compressed air.

Install the oil receiver in reverse order.

We clean the mating surfaces of the cylinder block, oil pump housing, crankshaft rear oil seal holder and oil pan from the remnants of the old gasket, sealant and oil.

We apply a thin layer of sealant at the junction of the oil pump housing and the crankshaft rear oil seal holder with the cylinder block.

Install the oil pan with a new gasket in reverse order.