The cylinder head is usually removed to replace its gasket, valves, valve guides, repair the head, as well as for a complete engine overhaul

The cylinder head can be removed as an assembly with the reservoir, intake pipe, fuel rail and catalytic converter, or by first removing these assemblies.

Dismantling and mounting of the head must be carried out on a flyover or on a lift.

Remove the engine screen.

Relieve the fuel pressure in the fuel system.

Disconnect the negative terminal from the battery.

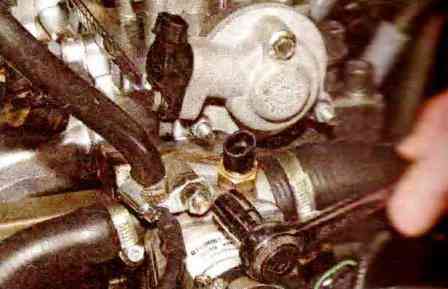

Disconnect the fuel supply hose from the fuel rail tube.

Drain the coolant from the engine.

Remove the air filter.

Remove the vacuum brake booster hose from the receiver pipe.

Disconnect the tips of the high-voltage wires from the spark plugs.

With a 13 head, unscrew the nut that secures the negative wire tip to the outlet pipe of the cooling system and remove the wire tip from the stud.

Loosen the clamps, remove the cooling system hoses from the outlet pipe and from the thermostat housing

Remove from the fittings of the throttle assembly the hose that drains the coolant from the assembly heating unit and the hose of the canister purge solenoid valve.

Disconnect the air supply hose from the nozzle of the throttle assembly.

Disconnect the wiring harness blocks of the engine management system and the wiring harness blocks of the fuel injectors and from the idle speed controller as well as from the sensors:

- - throttle position;

- - phases;

- - coolant temperature;

- - oxygen concentration.

Disconnect the wire blocks from the sensors for the coolant temperature gauge and emergency oil pressure.

After loosening the lower fastening nut and unscrewing the upper fastening nut of the coolant pump pipe bracket, we remove the bracket from the cylinder head stud.

Remove the left and right intake pipe support brackets.

Disconnect the additional muffler pipe from the collector.

Remove the cylinder head cover.

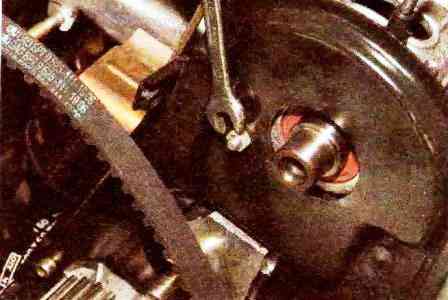

Remove the camshaft sprocket (see "Replacing the camshaft oil seal").

Using the “10” key, unscrew the nut of the upper fastening of the rear cover of the timing belt.

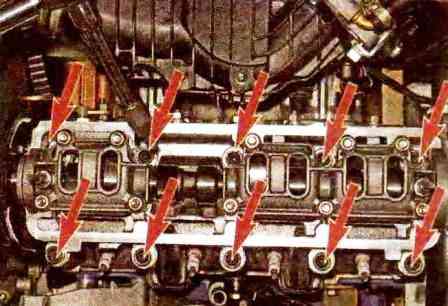

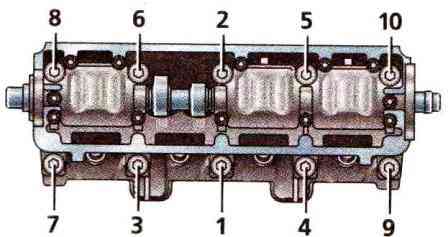

Using a “10” hexagon, we unscrew ten screws securing the cylinder head.

Remove the screws with washers.

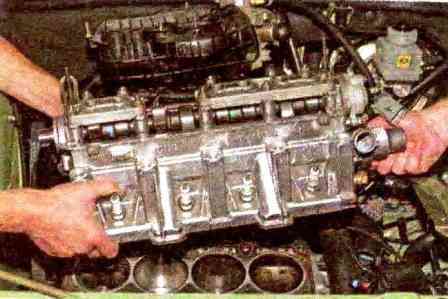

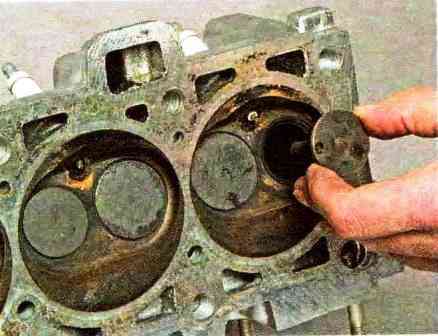

Remove the cylinder head assembly with the receiver, intake pipe, fuel rail and collector (it is more convenient to remove the head with an assistant).

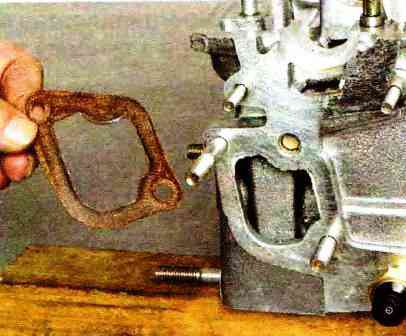

Remove the cylinder head gasket.

If it is necessary to dismantle the cylinder head, we dismantle the receiver, intake pipe and collector. We remove the camshaft (see "Removing the camshaft").

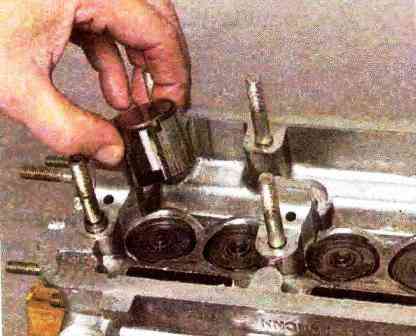

Having marked the installation location, we remove the valve lifters with shims from the sockets of the cylinder head.

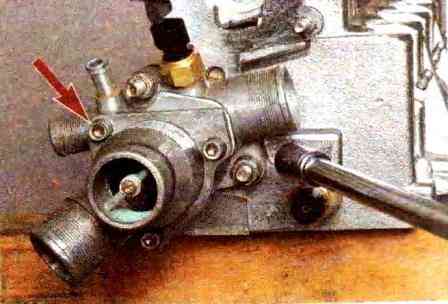

With a “13” head, we unscrew the two nuts securing the exhaust pipe.

Remove the pipe

Remove the gasket

Unscrew the coolant temperature indicator sensor.

Mark the valves with a marker.

When disassembling the valve mechanism, we put a stop (wooden block) under the plate of the valve being dried out.

We dry out the valve (see "Replacing valve oil seals") and remove the spring plate, outer and inner springs, support washer

Remove the valve from the guide sleeve.

Similarly, we dismantle other valves.

Before assembling the cylinder head, we remove carbon deposits from the surface of the combustion chambers with a metal brush.

We wash the cylinder head with kerosene and blow the oil channels with compressed air.

We assemble and install the cylinder head in the reverse order.

Before installing the valves, we clean them of carbon deposits and apply a thin layer of engine oil to the valve stems.

We clean the mating surfaces of the cylinder block, head and exhaust pipe from the remnants of old gaskets, dirt and oil.

We remove oil and coolant from the threaded holes of the cylinder block for the head screws.

We install a new cylinder head gasket and the head itself along two centering bushings.

We install the fastening screws and tighten them in four stages according to the scheme:

- first trick - tighten the screws with a torque of 20-25 Nm (2.0-2.5 kgcm);

- second method - tighten the screws with a torque of 70-85 Nm (7.0-8.5 kgcm);

- the third trick is to turn the screws 90°;

- The fourth trick is turning the screws 90˚.

The cylinder head screws can only be reinstalled if they have extended to a maximum length of 135.5 mm. If the length is longer, replace the screws with new ones.