Camshafts are replaced in the following cases:

- - pressure drop in the engine lubrication system. The cause of this malfunction is often increased wear on the camshaft journals and sockets in the camshaft bearing housings.

When the sockets are worn, the head of the block assembly is replaced, since the sockets are processed together with the bearing housing installed on the head;

- - valve knock with serviceable hydraulic pushers (see "How to replace the hydraulic compensators of the VAZ-21126 engine") in the valve mechanism.

It happens due to wear of the camshaft cams due to the use of low-quality engine oil or damage to the oil filter.

Remove the camshafts from the engine (see "Replacing the valve stem seals of the VAZ-21126 engine").

Inspect the camshafts.

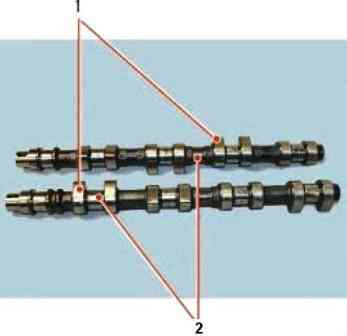

On the working surfaces of the necks 2, scuffing, nicks, scratches, aluminum enveloping from the bearing seats in the housings and the head of the block are not allowed.

On the working surfaces of the cams 1, scuffing and wear of more than 0.5 mm, as well as wear of the cams in the form of a cut, are not allowed.

Replace the shaft with detected defects.

In workshops equipped with special devices and tools, you can check the radial runout of the camshaft journals (it should not exceed 0.02 mm).

Measure the diameters of the bearing journals of the shaft. They should be 23.915–23.931 mm.

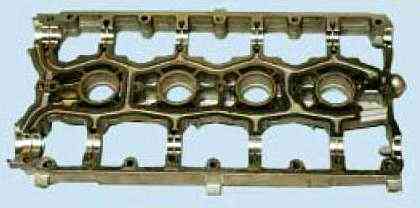

Inspect the bearing housing…

Inspect the camshaft bearings in the head.

Cracks on the hull are not allowed.

On the working surfaces of the supports under the necks, no marks, scratches, scuffs, excessive wear are allowed.

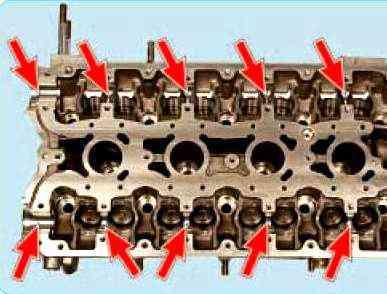

Install the camshaft bearing housing onto the block head and tighten its mounting bolts to the recommended torque.

Measure the inside diameters of the camshaft housing bearings. They should be 24.000–24.025 mm.

Calculate the gaps between the shaft journals and the bearings by the difference in size.

For new parts, the gaps should be 0.069–0.11 mm.

If after operation the gaps exceed 0.2 mm, replace the camshafts.

If, after replacing the shafts, the clearances exceed the maximum allowable value, replace the cylinder head assembly with the camshaft bearing housing.

Install the camshafts and all removed parts in the reverse order of removal.

Apply sealant to the surface of the cylinder head mating with the camshaft bearing housing in a bead of 2 mm diameter.