Removing the front wheel brake pads

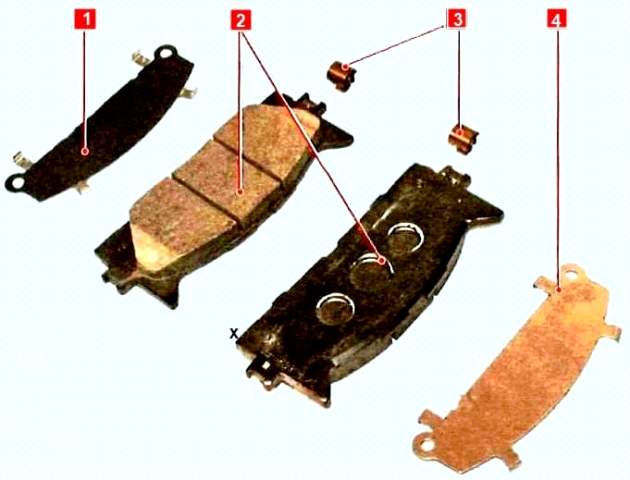

When replacing brake pads, always change the inner pads, outer pads and pad covers as a set

Drain the brake fluid.

Remove the front wheel and temporarily secure the rim with two nuts.

Remove the bolt and detach the brake hose bracket.

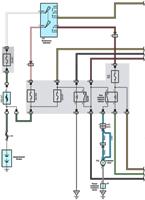

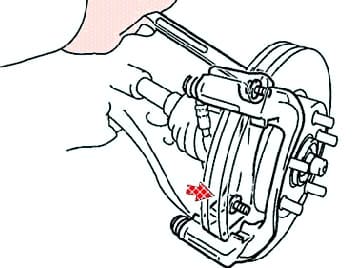

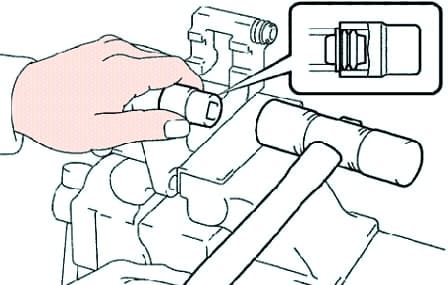

While holding the guide pins, unscrew the caliper mounting bolts (Fig. 1).

Raise the caliper and secure it with wire.

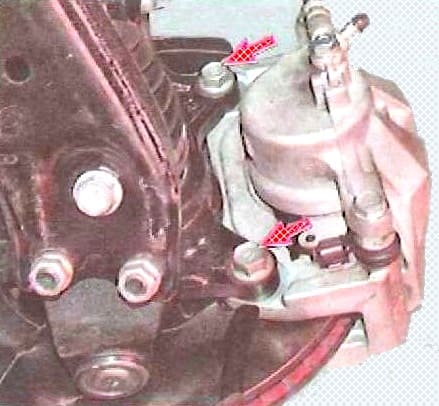

Remove the two anti-squeak springs, two brake pads, two anti-squeak pads holding the plate liners (fig. 2).

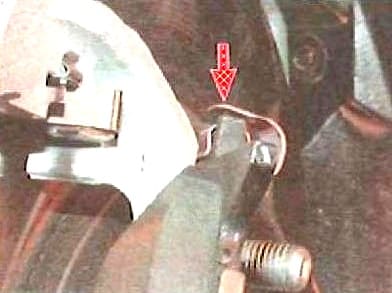

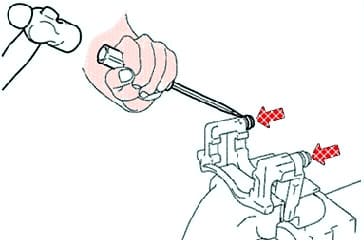

Use a thin-blade screwdriver to remove the pad wear indicators (fig. 3).

Remove the guide pins from the caliper (fig. 4).

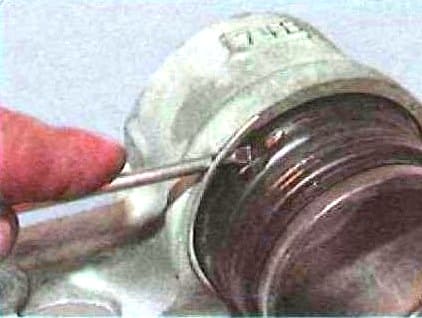

Use a thin-blade screwdriver to remove the O-rings from the guide pins (fig. 5).

Be careful not to damage the guide pin housing when removing the seal.

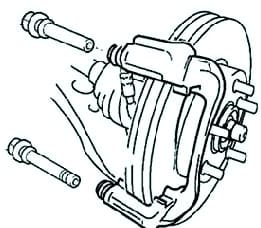

Unscrew the mounting bolts of the caliper body and remove the caliper (Fig. 6).

Holding the caliper in a soft-jawed vise, use a screwdriver and hammer to remove the guide pin boots (fig. 7).

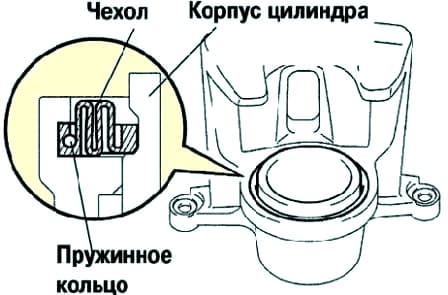

Using a screwdriver, remove the brake cylinder boot spring ring and boot (fig. 8).

Place a rag between piston and cylinder.

Using compressed air, remove the piston from the cylinder (fig. 9)

Using a screwdriver, remove the oil seal (fig. 10).

Checking the brake pads

Measure the thickness of the brake pads with a ruler (fig. 11).

- Standard thickness: 12mm

- Minimum thickness: 1.0 mm.

Checking the brake disc and brake components

Check for corrosion, wear and damage on the inner walls of the cylinder.

Replace the cylinder body if necessary.

Minor imperfections caused by corrosion or foreign particles can be removed by sanding the surface with fine emery cloth.

Replace the cylinder body if necessary.

Check for wear, cracks and damage.

If necessary, replace the corresponding component.

Check for corrosion, wear and damage on the piston surface.

If necessary, replace the corresponding component.

Check for corrosion, wear and damage on the guide pin and guide pin boot.

If necessary, replace the corresponding component.

Check for uneven wear, cracks and serious damage on the surface of the brake disc.

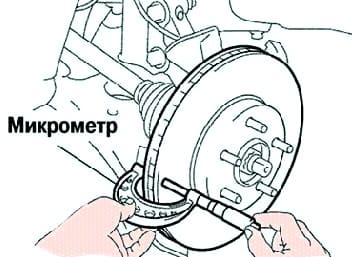

Measuring the brake disc thickness

Using a micrometer, measure the thickness of the brake disc (fig. 12).

- Standard thickness: 28mm

- Minimum thickness: 26mm

Replace the disc if the disc is less than the minimum thickness.

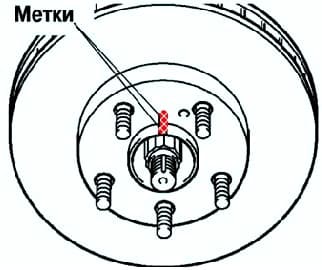

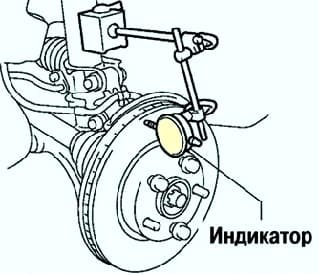

Brake disc runout measurement

Mark the brake disc and wheel hub axle bush (fig. 13).

Attach the brake disc to the wheel hub with wheel nuts (2 or more locations).

Check the runout with an indicator (fig. 14).

Measuring point: 10 mm from the outer edge of the disc. maximum runout: 0.05mm or less.

Make sure the end play is 0 mm before measuring.

If the runout is significant, find the point of minimum runout by sequentially shifting the installation position of the brake disc on the hub by one hole.

Assembly

Apply lithium rubber grease to the piston seals and install them in the cylinder body (fig. 15).

When installing, do not use too much force so as not to damage the parts.

Install the spring ring of the brake cylinder boot and the boot (fig. 16).

Using a socket wrench (19 mm) and a hammer, install the guide pin boots (fig. 17).

Pre-lubricate the anthers with lithium grease.

Install the brake cylinder housing onto the brake disc and tighten the fixing bolts. Tightening torque: 107 Nm.

Install the guide pins.

Install the brake pads.

Install the caliper. Tighten the mounting bolts. Tightening torque: 34 Nm.

Install the brake hose and tighten the fastening nut. Tightening torque: 29 Nm.

Pour the brake fluid into the barrel.

Check for brake fluid oozing from the master cylinder.

Check the pipes and hoses of the brake system.

Bleed your brakes.

Install the wheels.