Vertical downdraft carburetor with balanced float chamber. Two-chamber carburetor, each chamber has two diffusers

The required composition of the mixture is obtained by pneumatic braking of the fuel and the use of an economizer valve (with a mechanical drive).

The carburetor has a separate idle system for each chamber, powered from the main fuel channel, to enrich the mixture when the throttle valves are suddenly opened, the carburetor has a mechanically driven accelerator pump.

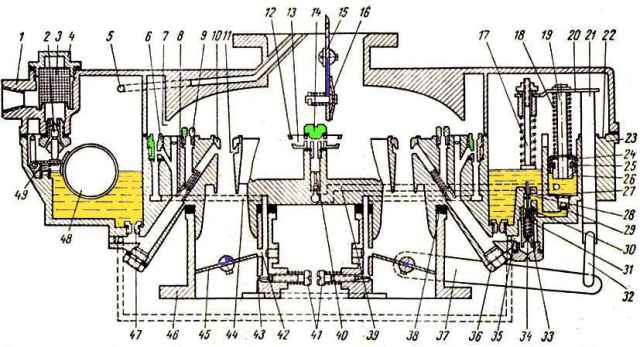

K88 carburetor: 1 - air inlet body; 2 - needle valve for fuel supply; 3 - mesh filter; 4 - filter plug; 5 - channel for balancing the float chamber; 6 - idle jet; 7 - cavity; 8 - full power jet; 9 - air jet; 10 - small diffuser; 11 - annular gap; 12 - nozzle; 13 - air cavity; 14 - hollow screw; 15 - air damper; 16 - automatic valve; 17 - pusher; 18 and 34 - spring; 19 and 21 - rods; 20 - bar; 22-ring groove; 23 - body of the float chamber; 24 - cuff; 25 - cuff spring; 26 - stem bushing; 27 - hole; 28 - intermediate pusher; 29 - ball inlet valve; 30 - saddle; 81 - ball valve; 32 - thrust; 33 mechanically driven economizer valve; 35 - fuel channel; 36 - cork; 37 - lever; 38 - gasket; 39 - channel; 40 - needle discharge valve; 41 - idle adjustment screws; 42 - rectangular hole; 43 - hole of the idle system; 44 - channel; 45 - throttle valve; 46 - body of mixing chambers; 47 - main jet; 48 - float; 49 - float spring

To facilitate starting a cold engine, the carburetor has an air damper with an automatic valve and a kinematic connection between the air and throttle valves.

The float chamber, accelerator pump, economizer and air damper are common to both chambers.

The carburetor has a built-in actuator for a pneumatic centrifugal limiter for the maximum number of revolutions of the engine crankshaft.

The carburetor consists of three main parts: air inlet body 1, float chamber body 23 and mixing chamber body 46.

The air inlet housing contains:

- - air damper 5 with automatic valve 16,

- - mesh filter 3,

- - stopper 4 filters,

- - needle valve 2 for fuel supply and injectors 12 for the accelerator pump, cast in one piece with the carburetor air inlet body.

The body of the float chamber contains:

- - float 48 with spring 49,

- - piston of the accelerator pump, consisting of cuff 24, spring 25 and bushing 26 of the rod,

- - ball inlet 29 and needle discharge 40 valves of the accelerator pump,

- - valve 33 of the economizer with a mechanical drive,

- - two main jets 47,

- - two jets 6 idling,

- - two jets 8 full power,

- - two air jets 9.

In the body of the mixing chambers there are throttle valves 45, two screws. 41 quality idle speed adjustments and a stop screw.

The throttle shaft is mounted on bearings.

On the roller, on the side of the diaphragm mechanism housing, there is a cuff pressed by a spring.

In the housing of the diaphragm mechanism there is a rod with a diaphragm, a spring and a throttle shaft lever.

From the outside, the case is closed with covers

K-88A carburetor basic data

Diffuser diameter in mm:

- - small 8.5

- - big 29.0

Mixing chamber diameter in mm 36.0

- air inlet 60.0

Capacity of dosing elements when tested with water under pressure of 1000 mm at a temperature of 20±1°C in cm 3/min:

- - main jet 315

- - full power jet 1150

- - economizer valve 215

- - air jet (diameter) in mm 2.2

- - idle jet (diameter) in mm 0.6

Distance from the fuel level in the float chamber to the upper plane of the float chamber housing connector in mm 18—19

Float weight in (g) 19.7±0.5

Distance between the edge of the throttle valve and the wall of the mixing chamber corresponding to the opening moment of the mechanically operated economizer valve, in mm 9.0