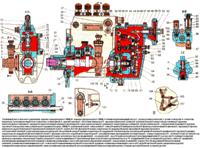

K-151, K-151D carburetor adjustment

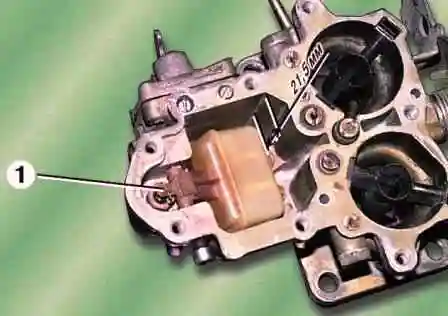

The fuel level in the float chamber is adjusted with the carburetor cover removed

However, without disconnecting the trigger rod, you can unscrew the screws that secure the cover, lift it up and, having removed the gasket, turn the cover to the side as far as the gaps in the places where the rod is attached will allow.

Pump gasoline into the float chamber with the fuel pump manual priming lever until the level stabilizes.

The distance from the fuel level to the upper plane of the carburetor body should be 21.5 mm.

When the fuel level is below the specified one, it is necessary to bend up the tongue 1 of the float, which rests against the shank of the shut-off valve needle.

When the tongue is raised, bend it down.

After each bending of the tongue, it is necessary to unscrew the drain plug of the float chamber, drain the gasoline from it and, screwing the plug back in place, re-pump the gasoline with the fuel pump manual priming lever

You can adjust the starting system directly on the car by fully warming up the engine and connecting a tachometer to it.

Starting the engine with the air filter removed and lightly depressing the accelerator pedal, fully close the air damper with its actuator handle.

Then, use a screwdriver blade to slightly open the air damper as far as the lever mechanism allows.

The engine speed should be 2500–2700 min –1 .

If it differs from the specified one, loosen the lock nut on the adjusting screw resting against the profile lever, tighten or unscrew this screw

Tighten the locknut tightly after adjustment is complete.

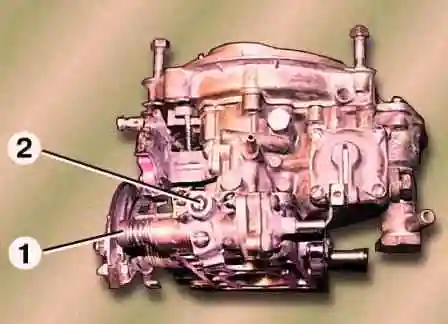

Adjust the idle system on a warm engine with a tachometer connected to it.

To do this, with the engine running, set quality screw 2 to a position that ensures maximum idling speed.

Then, using the quantity screw 1, set the frequency increased by 100–120 min –1 .

After that, tighten the quality screw until the speed is reduced by 100–120 min –1 .

This method of adjustment allows you to meet the emission standards.

However, a more precise adjustment is recommended using a gas analyzer.

Check

Check the operation of the accelerator pump with the carburetor cap removed after adjusting the fuel level.

When the throttle valves are suddenly opened, an even strong jet of gasoline should come out of the accelerator pump nozzle, reaching the channels of the throttle body without touching the walls of the diffusers.

An uneven and curved jet indicates a partial clogging of the atomizer channels.

In the absence of a jet, make sure that the fuel supply screw of the atomizer and the delivery valve located in it are clean and in good condition.

If they are in good condition, you should check the cleanliness and serviceability of the diaphragm mechanism of the accelerator pump by disassembling it, as described above.