A sealing gasket is installed between the flanges of the cylinder head and the manifold, made of two thin molded metal strips, interconnected by spot welding

If the gasket is leaking, the exhaust gases will burst outward, accompanied by a characteristic sharp sound.

If the malfunction cannot be eliminated by tightening the collector fastening, replace the gasket

You will need: wrenches "for 10", "for 13", socket head "for 13", pliers, ruler, blade probe.

Removing the gasket of the engine collector

Disconnect the wire from the negative terminal of the battery.

Remove the decorative engine cover.

Disconnect the exhaust pipe of the additional muffler from the collector, for which unscrew the nuts securing the exhaust pipe flange to the collector flange

Disconnect the suspension cushion from the muffler brackets and remove the exhaust pipe flange from the studs of the collector flange.

Remove the additional muffler.

Remove the decorative engine cover.

Disconnect the exhaust pipe of the additional muffler from the collector, for which unscrew the nuts securing the exhaust pipe flange to the collector flange

Disconnect the suspension cushion from the muffler brackets and remove the exhaust pipe flange from the studs of the collector flange.

Remove the additional muffler.

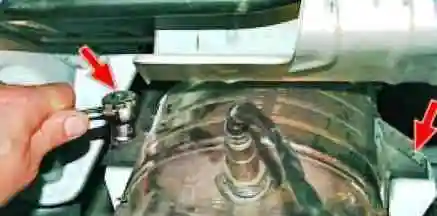

Press out the clamps of the harness block

Disconnect the wiring harness connectors for the control and diagnostic oxygen concentration sensors from the engine harness.

Press out the tendrils of the holders

Disconnect the harness holders for the control and diagnostic oxygen sensors from the steering gear heat shield.

Unscrew the bolts securing the collector to the bracket with a “13” socket head.

Using a 10 wrench, unscrew the three nuts securing the heat shield of the steering gear to the engine shield (two nuts are located under the steering gear)

Remove the shield.

Unscrew the two nuts securing the water pump inlet pipe bracket with a 13 wrench

Remove the bracket.

Unscrew the eight nuts securing the collector to the cylinder head with a 13 wrench

Remove the collector

Remove the gasket

Install the new gasket and all removed parts in the reverse order of removal.

Check the flatness of the collector flange surface.

To do this, place the ruler with an edge on the flange surface and measure the gap between the flange plane and the ruler with a feeler gauge.

Grind the flange surface or replace the collector if the gap exceeds 0.1 mm.

In order to avoid sticking of the gasket and to increase its tightness, we recommend that you lubricate the gasket on both sides with a thin layer of graphite grease before installation.

Lubricate the exhaust manifold mounting studs with graphite grease.