If an oil leak through the oil sump seal cannot be eliminated by tightening its fastening bolts, it means that the seal is severely deformed and must be replaced

Perform work on a viewing ditch, overpass or, if possible, on a lift.

Drain the engine oil (see "Changing the engine oil and oil filter").

Remove mudguards and crankcase protection.

Disconnect the downpipe from the exhaust manifold.

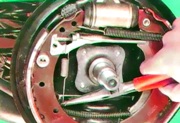

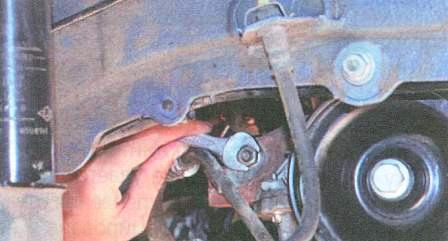

Using a screwdriver, move the front exhaust suspension mount.

Remove the system bracket from the cushion.

We take the downpipe down

Fix the system in this position in any way possible (for example, by tying it with wire).

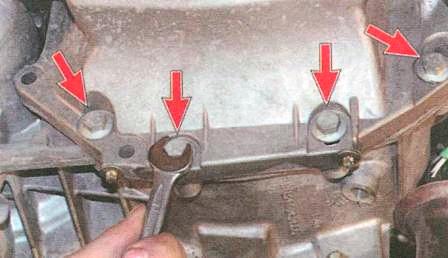

Remove the four bolts securing the oil sump to the clutch housing...

We unscrew the five bolts of fastening to the cylinder block in front.

We turn out seven bolts on the right.

- and on the left, as well as two bolts on the back.

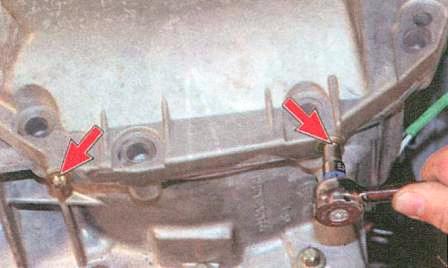

On the right front side of the engine, remove the bolt securing the accessory bracket to the oil pan

Disconnect the front bumper attachments to the subframe, the front subframe attachments to the body, remove the subframe tie rods, loosen its rear attachments, lower the front part of the subframe down enough to allow the oil sump to be removed, and place supports under the subframe.

It is necessary to detach the subframe because it does not allow you to remove the oil sump.

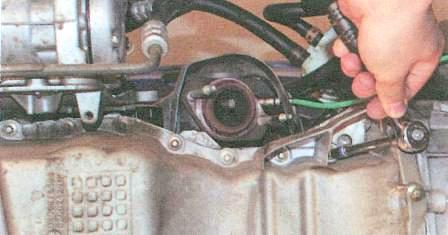

Remove the bolt securing the pipeline holder to the engine.

We unscrew the bolt securing the air conditioner compressor bracket to the oil casing, which simultaneously secures the second pipeline holder

Pull the pipeline aside and remove the oil pan

Remove the gasket from the crankcase grooves

Clean and degrease the crankcase grooves, put a new gasket in them.

Clean off the remnants of the old gasket and degrease the mating surface of the cylinder block.

Install the oil sump, screw in the twenty bolts of its fastening to the cylinder block, without completely tightening it.

Full tighten the four bolts securing the oil sump to the clutch housing (see operation 8), without completely tightening them.

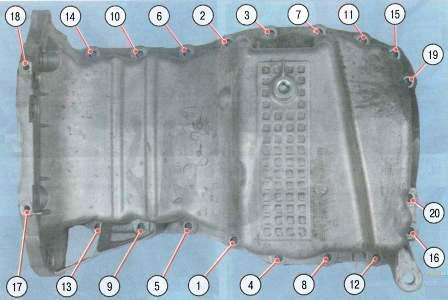

Tighten the bolts securing the oil sump to the cylinder block in the order shown in the figure, preliminarily with a torque of 8 Nm (0.8 kgf-m), and then finally with a torque of 14 Nm (1.4 kgf-m).

Then, tighten the four bolts securing the oil sump to the clutch housing to 27 Nm (2.7 kgf-m).

The order of tightening the oil sump bolts is shown on the removed sump for clarity.

Install all removed parts and assemblies in the reverse order of removal

Fill engine oil.