With a certain skill and care, many malfunctions of the engine and its systems can be quite accurately determined by the color of the smoke coming out of the exhaust pipe

Blue smoke indicates that oil has entered the combustion chambers, and constant smoke is a sign of severe wear of the parts of the cylinder-piston group.

The appearance of smoke during regassing, after prolonged cranking by the starter, after long idling or immediately after engine braking, as a rule, indicates wear on the valve stem seals.

Black smoke is a sign of too rich a mixture due to a malfunction of the engine control system or injectors.

Blue or thick white smoke with moisture (especially after the engine has overheated) means that coolant entered the combustion chamber through a damaged cylinder head gasket.

If this gasket is severely damaged, the liquid sometimes penetrates into the oil sump, the oil level rises sharply, and the oil itself turns into a cloudy whitish emulsion.

White smoke (steam) is normal when the engine is cold in wet or cold weather.

It is quite common to see a car parked in the middle of a city traffic jam with its hood open, emitting puffs of steam.

Engine overheating

It is better, of course, not to allow this, often looking at the temperature gauge.

But no one is immune from the fact that the thermostat, electric fan may suddenly fail, or the coolant may simply leak.

If you miss the moment of overheating, do not panic and do not aggravate the situation. Overheating is not as bad as its possible consequences.

Never turn off the engine immediately - it will suffer heat stroke and possibly cool down and refuse to start at all.

Having stopped, let it idle, then the fluid will continue to circulate in the system.

Turn on the heater to maximum power and open the hood.

If possible, pour cold water over the radiator. Stop the engine only when the temperature drops.

But never immediately open the cap of the expansion tank: on an overheated engine, a geyser from under the open cap is provided.

Take your time, let everything cool down, so you save the health of the machine and your own health.

Almost all instructions for the car contain a recommendation to depress the clutch when starting the engine.

This recommendation is justified only in case of starting in severe frost, so as not to waste battery energy on turning the shafts and gears of the gearbox in thickened oil.

In other cases, this is just a recommendation so that the car does not start if the gear is engaged due to forgetfulness.

This technique is harmful to the engine, since a significant force is transmitted to the crankshaft thrust bearing through the depressed clutch, and during start-up (especially cold), lubrication is not supplied to it for a long time.

The bearing wears out quickly, the crankshaft receives axial play, starting off begins to be accompanied by strong vibration.

In order not to spoil the engine, make it a habit to check the position of the gear lever before starting and start the engine with the parking brake applied, without depressing the clutch unless absolutely necessary.

Cause of malfunction - Remedy

No rail pressure

Clogged fuel lines - Flush and bleed fuel lines

Fuel pump defective - Replace pump

Clogged fuel filter - Replace filter

Fuel pressure regulator defective - Replace regulator

Faulty ignition system - See Checking the Ignition System

Engine runs erratically or stalls at idle

Insufficient fuel rail pressure - See Engine Won't Start

Faulty idle speed control - Replace idle speed control

Air leakage through the crankcase ventilation hoses and the hose connecting the intake pipe to the vacuum - Tighten the fastening clamps, replace damaged hoses

The gaps in the valve drive mechanism are broken - Check the hydraulic lifters, replace the faulty ones

Faulty ignition system - See "Engine Management System"

The engine does not develop full power and is not fast enough

Incomplete throttle opening - Adjust the throttle actuator. See - "Adjusting the throttle cable"

Faulty throttle position sensor - Replace sensor

Air filter dirty - Replace filter element

Faulty ignition system - See "Electronic Engine Management System"

The gaps in the valve drive mechanism are broken - Check the hydraulic pushers, replace the faulty ones. See "Replacing hydraulic lifters".

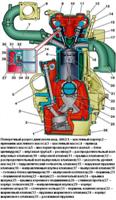

Insufficient compression - below 10kgf/cm2

Cylinder head gasket punctured - Replace gasket

Piston burn-out, breakage or sticking of piston rings - Clean rings and piston grooves from carbon deposits, replace damaged rings and piston

Poor fit of valves to seats - Replace damaged valves, grind seats

Excessive wear on cylinders and piston rings - Replace pistons, bore and hone cylinders

Insufficient oil pressure in a warm engine

Using the wrong brand of oil - Change the oil

Oil thinning or foaming due to fuel or coolant intrusion into the sump - Eliminate the cause of the intrusion. Change the oil.

Contamination of the working cavity or wear of the oil pump parts - Flush, repair or replace the oil pump

Clogged oil filter - Change filter

Loose or clogged oil receiver - Flush the oil receiver and secure it.

Oil receiver damaged - Replace oil receiver

Increased clearance between crankshaft main and connecting rod bearing shells - Grind crankshaft and replace bearing shells

Cracks, pores in the walls of the oil passages of the cylinder block or clogging of the oil lines - Repair the cylinder block. Replace the block if not possible.

Loose installation of oil channel plugs or their absence - Restore the tightness of the plugs, install the missing plugs