After a long stop, the noise that disappears after a few seconds after starting the engine is not a sign of a malfunction:

- - since some of the hydraulic pushers, which were under the load of the valve springs of the open valves (the oil supply channels remained open), oil leaked out, the lack of which is replenished at the beginning of the engine operation

*The following reasons for increased noise in idle mode are possible, which increases with increasing crankshaft speed up to 1500 min-1 and is not associated with the operation of hydraulic pushers:

- - increased clearances between valve stems and guide bushings;

- - valve and seat misalignment increased to a value exceeding the allowable value;

- - non-parallelism of the ends of the valve springs;

- - more than allowable runout of the valve head chamfer.

Increased noise immediately after starting the engine:

Oil leakage from part of the hydraulic pushers during a long stop.

The noise that disappears a few seconds after starting the engine is not a sign of a malfunction, since oil leaked out from a part of the hydraulic pushers that were under the load of the valve springs of the open valves (the oil supply channels remained open), the lack of which is replenished at the start of the engine operation

Intermittent idle noise that disappears as engine speed increases:

- Damage or wear of the check valve ball

- - Pollution of the hydraulic pusher mechanism with wear products due to untimely oil changes or its low quality

Clean the parts of the mechanism from dirt. Use the oil recommended in the owner's manual

Increased noise during idling of a warm engine, disappearing at an increased crankshaft speed and completely absent on a cold engine:

- - Oil flow through the gaps increased due to wear between the plunger and the hydraulic pusher sleeve

Replace worn hydraulic tappet assembly

Increased noise that occurs at high crankshaft speed and disappears at low speed:

- - Foaming with excess oil (above the upper mark on the dipstick) in the oil sump due to its agitation by the crankshaft. The ingress of an air-foam oil mixture into the hydraulic pushers disrupts their operation

Top up the oil level in the oil sump

- - Air intake by the oil pump when the oil level in the oil sump is too low

Top up the oil level in the oil sump

- - Damage to the oil receiver due to deformation of the oil sump when hitting a road obstacle

Repair or replace defective parts

Constant noise from one or more valves, independent of engine speed:

- - The occurrence of a gap between the pusher and the camshaft cam due to damage or contamination of the parts of the hydraulic pusher

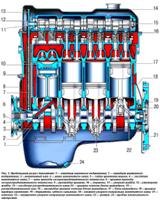

Remove the cylinder head cover, install the camshaft cams alternately with the projections up and check for a gap between the pushers and the cams.

Sinking (for example, with a wooden wedge) the hydraulic pusher to be checked, compare the speed of its movement with the others.

If there is a gap or an increased travel speed, disassemble the hydraulic pusher and clean its parts from dirt or replace the hydraulic pusher