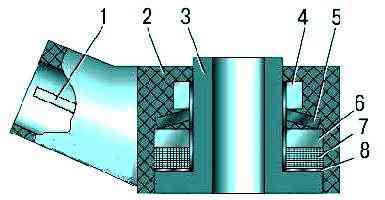

Knock sensor (0261231046 Bosch or GT 305) piezoelectric type mounted on the engine block under the intake manifold of the fourth cylinder

The sensor senses block wall vibrations caused by shock waves generated during detonation combustion in the cylinders and outputs an alternating voltage to the connecting contacts corresponding to the level of engine knock.

The control unit filters out signals resulting from random mechanical influences.

If the sensor fails or there is a malfunction in its circuit, the electronic control unit will switch to the standby mode of operation with a deliberately late ignition timing, turn on the KMSUD signaling lamp and write a fault code to the memory (see "Diagnostics of the ZMZ-406 engine control system" ).

Knock sensor test

Turn off the ignition and remove the negative battery terminal.

Using the “13” key, we unscrew the nut that secures the sensor to the cylinder block wall

(intake manifold removed for clarity)

Prying off the spring clip of the block with a thin screwdriver, disconnect the block of wires from the sensor.

We connect a voltmeter to the sensor terminals and, lightly tapping the sensor body with a solid object, we observe a change in voltage

The absence of voltage pulses indicates a sensor malfunction.

It is possible to be completely sure of a sensor malfunction only on a special vibration stand

Install the sensor in reverse order.