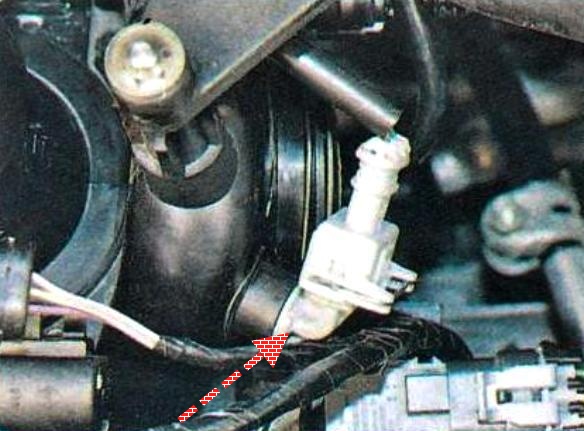

The sensor for top dead center and crankshaft speed, consisting of a magnet and a winding, is mounted on top of the clutch housing

If a malfunction occurs in the sensor circuit, the engine stops working, the controller memorizes the malfunction code and turns on the signal lamp in the instrument cluster.

In this case, check the sensor and ring gear for missing teeth, runout or other damage.

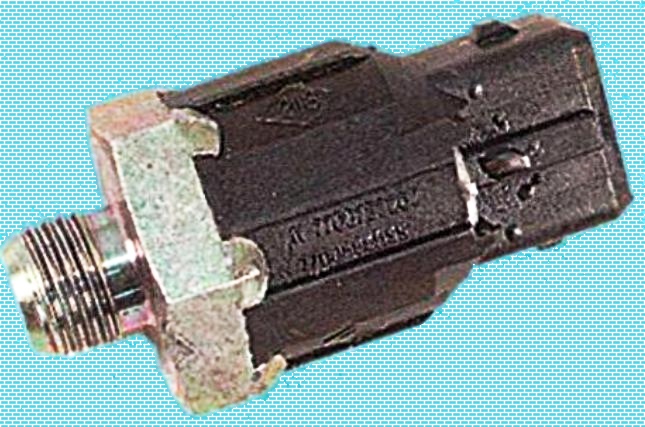

Replacing the crankshaft sensor

You will need: a key "for 10", a tester.

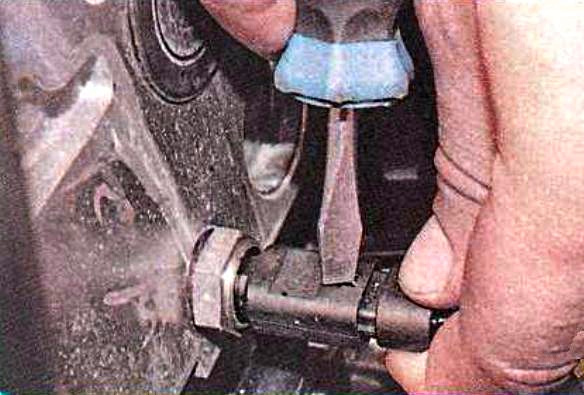

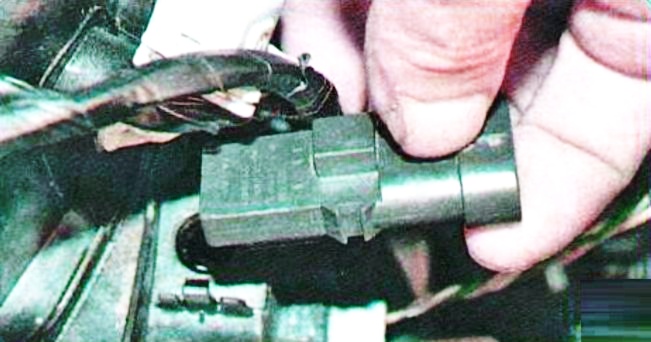

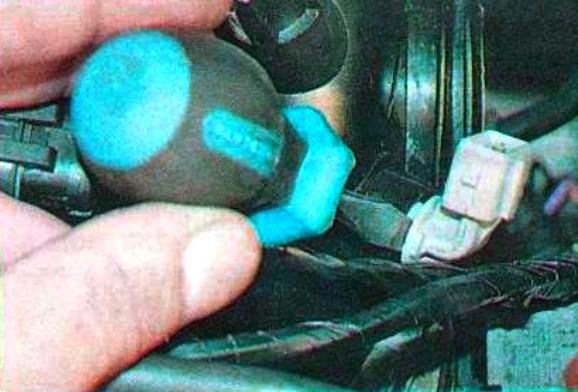

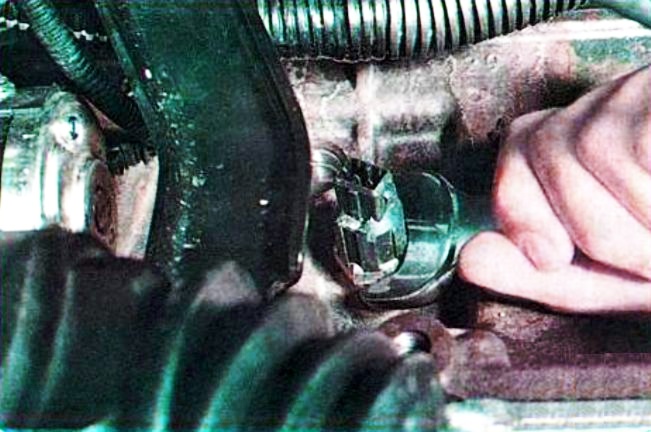

Using a screwdriver, we press the lock of the sensor wire block

Disconnect the wire from the negative terminal of the battery.

Disconnect the sensor harness connector.

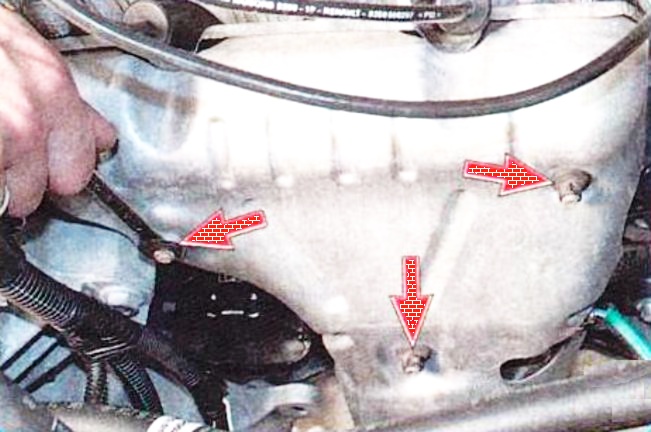

Remove the two sensor mounting bolts and remove the sensor.

Install the TDC and crankshaft speed sensor in the reverse order of removal.

In order to verify the correct operation of the fuel injection system after replacing the top dead center sensor and the speed of rotation of the crankshaft or flywheel, it is necessary to perform a test using a special device, which includes the following:

deceleration of the car with a fuel cut in 2.3.4 or 5th gear at an engine speed of 3500-3000 min for at least 2 s;

- -repeated deceleration with fuel cut-off in 2nd, 3rd, 4th or 5th gear at an engine speed of 2400-2000 min for at least 3 s;

- - check for fault codes and, if necessary, troubleshoot;

- - erase codes.

Replacing the coolant temperature sensor

The coolant temperature sensor is installed at the end of the cylinder head on the side of the 1st cylinder.

The sensor is an NTC thermistor: the electrical resistance of the sensor decreases with increasing temperature.

E6U processes the sensor signal and sets the optimal enrichment of the working mixture when the engine warms up.

You will need: 21 wrench, flat blade screwdriver, tester, thermometer.

Disconnect the wire from the negative terminal of the battery.

Drain the coolant.

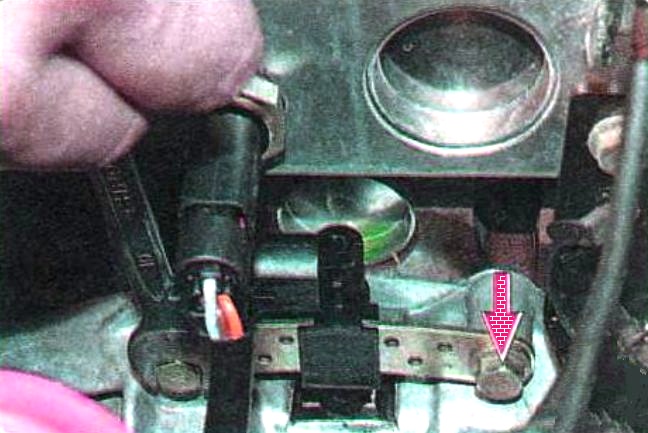

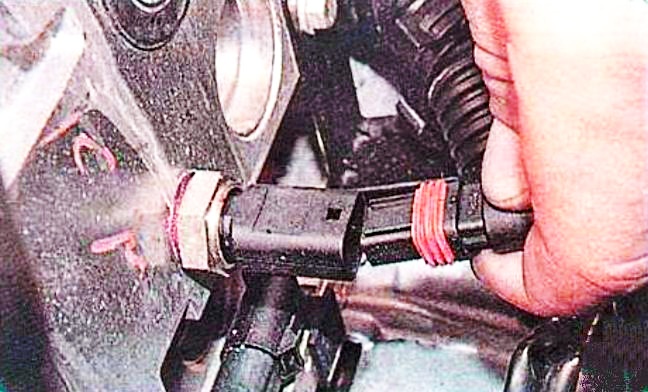

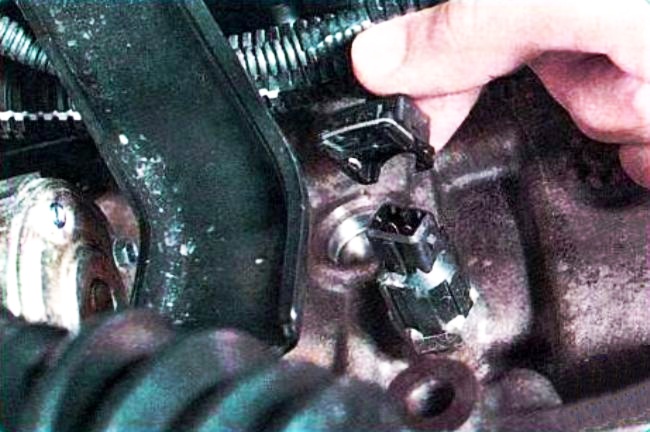

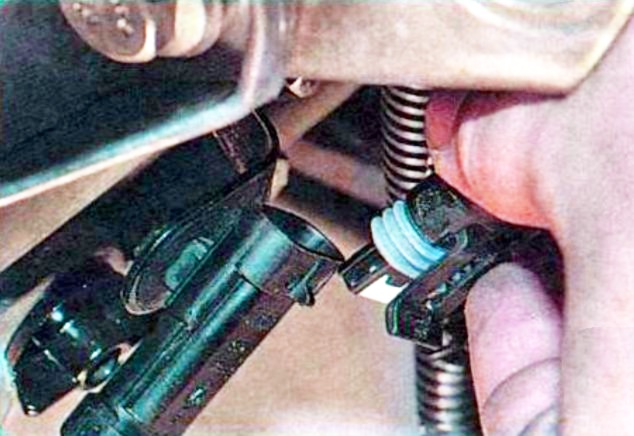

Press out the retainer with a screwdriver (fig. 6) and disconnect the wiring harness block from the coolant temperature sensor.

Loosen the sensor with a wrench and unscrew it by hand.

Install the parts in the reverse order of removal.

Refill coolant.

Replacing the throttle position sensor

The throttle position sensor is a potentiometer that is mounted on the throttle shaft.

The rotation of the damper axis causes a change in the voltage of the sensor signal, by which the ECU determines the degree of throttle opening.

If there is a malfunction of the engine at idle or a deterioration in acceleration dynamics, check the sensor and its connector.

You will need: TORX T20 wrench, tester.

Disconnect the wire from the negative terminal of the battery.

Remove the air filter.

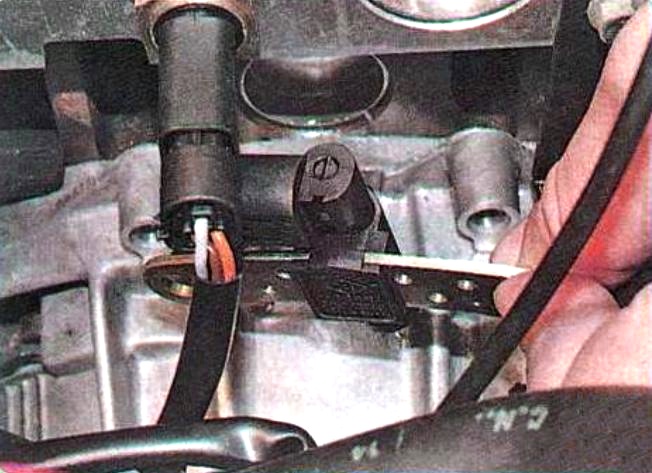

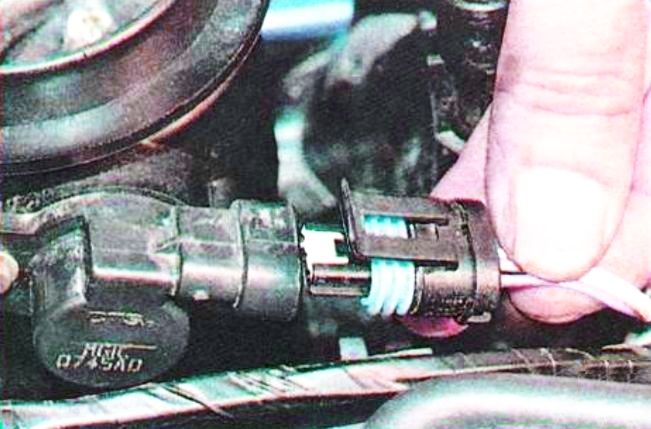

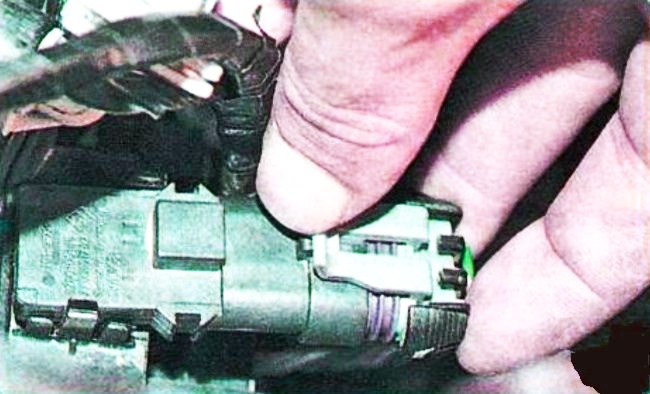

Press the latch and disconnect the wiring harness block from the sensor.

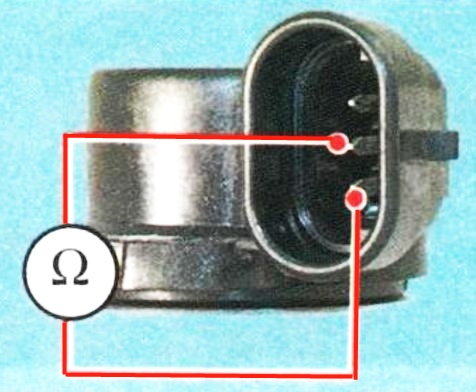

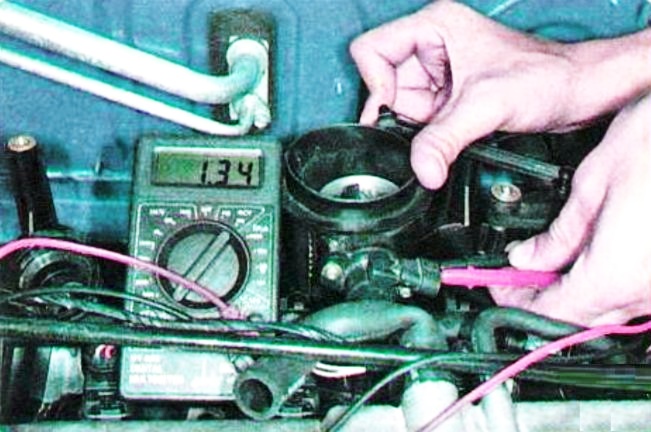

Connect the tester in resistance measurement mode to terminals "B" and "C" of the sensor.

Measure the resistance across the sensor leads with the throttle fully closed.

It should be 2.3-2.4 kOhm.

Turn the throttle by hand until it is fully open and measure the resistance again.

It should be 1.3-1.4 kOhm.

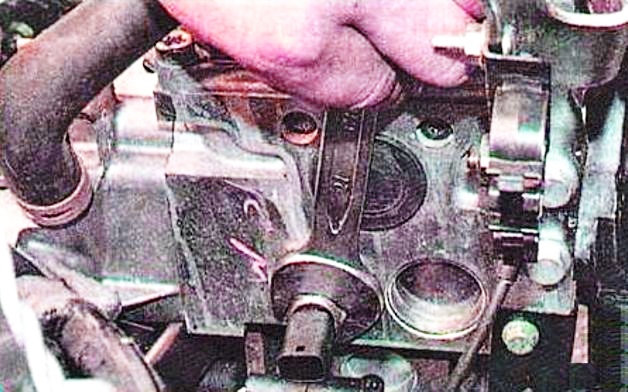

To replace the sensor, unscrew the two bolts of its fastening (for clarity, it is shown on the removed throttle assembly) and remove the throttle position sensor.

Install the parts in the reverse order of removal.

Replacing the absolute pressure sensor in the intake pipe

The absolute pressure (vacuum) sensor in the intake pipe is installed on the intake pipe.

The sensor detects the change in pressure (vacuum) in the intake pipe depending on the change in load and engine speed and converts them into an output signal voltage.

Depending on the sensor signal, the ECU calculates the amount of air entering the engine.

Disconnect the wire from the negative terminal of the battery.

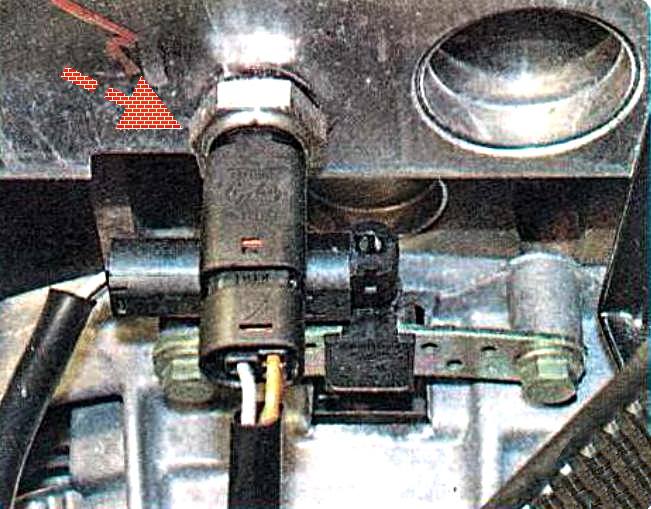

Press out the latch and disconnect the wiring harness block from the sensor.

Carefully remove the absolute pressure sensor, overcoming the resistance of the sealing rubber rings (the sensor fitting is installed with an interference fit in the intake pipe opening).

Install the sensor in the reverse order of removal

Replacing the air temperature sensor in the intake pipe

The air temperature sensor in the intake pipe is installed on the intake pipe next to the throttle assembly.

The sensor is an NTC thermistor: the electrical resistance of the sensor decreases with increasing temperature.

The electronic control unit regulates the amount of injected fuel based on the air temperature information from the sensor.

You will need a flat-blade screwdriver.

Disconnect the wire from the negative terminal of the battery.

Remove the air filter

Disconnect the wiring harness connector from the sensor by squeezing the spring clip with your fingers.

Pry off with a screwdriver and remove the sensor.

Install the sensor in the reverse order of removal.

Replacing the knock sensor

A knock sensor attached to the cylinder block between the 2nd and 3rd cylinders detects abnormalth vibrations (knocks) in the engine.

It is more convenient to replace the sensor on a car mounted on a lift, since access to the sensor from above is very difficult.

You will need a 24 key.

Disconnect the wire from the negative terminal of the battery.

Squeeze the latch and disconnect the wiring harness block from the sensor.

Unscrew the knock sensor and remove it

Install the parts in the reverse order of removal.

Oxygen sensor replacement

An oxygen concentration sensor (lambda probe) is installed on the exhaust manifold.

On some vehicles, the second sensor is installed behind the catalytic converter.

The sensor measures the oxygen content in the exhaust gases and converts the measured value into a signal voltage that is supplied to the electronic engine control unit.

Using the signals from the sensor, the ECU controls the fuel injection in such a way as to obtain the calculated composition of the air-fuel mixture.

If the oxygen concentration sensor is defective, the toxicity of exhaust gases may increase dramatically.

You will need: keys "for 10", "for 22".

Disconnect the wire from the negative terminal of the battery.

Press the latch and disconnect the wiring harness block.

Remove the pad from the bracket by sliding it forward.

Unscrew the three nuts and remove the heat shield.

Remove the wire from the holder.

Loosen and unscrew the sensor from the exhaust manifold.

Install the sensor in the reverse order of removal.

Replacing the vehicle speed sensor

The vehicle speed sensor is mounted on the gearbox and is a Hall effect sensor.

It sends a pulse signal to the electronic engine control unit proportional to the speed of the drive wheels.

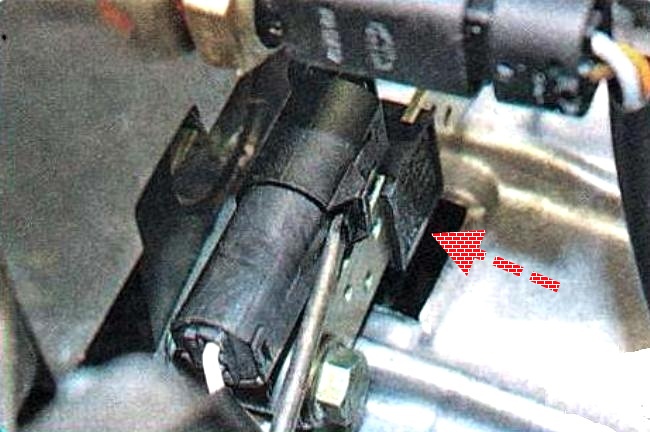

To replace the speed sensor, disconnect the wire from the negative terminal of the battery.

Press the latch and disconnect the wiring harness connector from the speed sensor.

Carefully pry off the speed sensor with a screwdriver, remove it from the gearbox housing.

Install the speed sensor in the reverse order of removal.