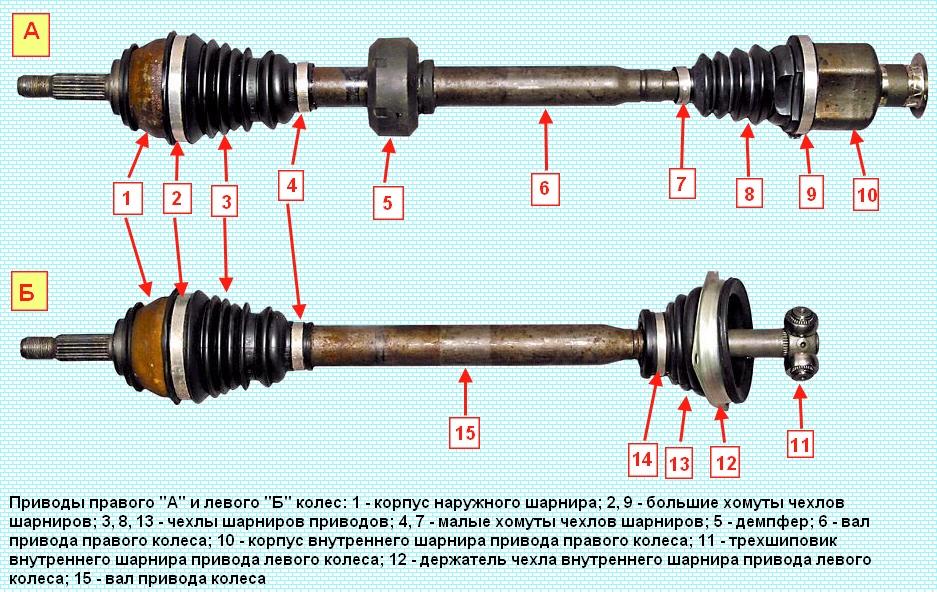

The front wheel drives consist of external and internal constant velocity joints (CV joints) connected by shafts

The external hinge allows only angular movements of the connected shafts

The internal hinge, in addition to the angular ones, also provides axial displacement of the shafts when the front wheels turn and the suspension works.

All hinges of both drives are of the "Tripod" type, and the outer hinges of both drives are the same in design, while the inner ones are ~ different.

Therefore, the right and left drives are not interchangeable.

To reduce vibration in the transmission, a dynamic damper is installed with an interference fit on the shaft of the right drive

On a Renault Logan car, external hinges of the GE 86 type and internal types of GL 69 (left) and RC 462 (right) are used

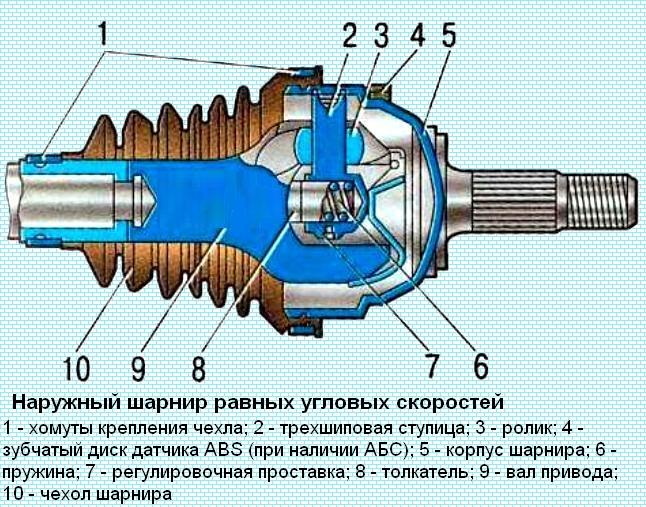

The outer hinge 2 consists of a body 5 (Fig. 2) and three rollers 3 put on the trunnions of a three-pin hub 2. The latter is made in one piece with the hinge body.

The rollers enter the grooves of the hinge cage, made in one piece with the drive shaft 9.

This design allows the hinge to rotate to the required angle.

The splined shank of the outer joint housing is secured to the front wheel hub with a nut.

The sealing of the hinge is provided by a cover 10, fixed with clamps 1 on the hinge body and on the drive shaft.

For the repair of the external hinge, only its cover and cover fastening clamps are supplied as spare parts.

In case of failure, the hinge must be replaced as an assembly with the drive shaft, since the hinge cage forms a non-separable unit with the shaft.

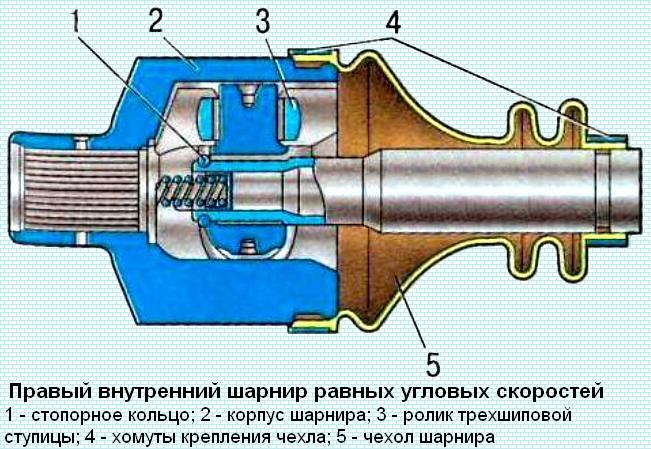

The right inner hinge consists of a body 2 (Fig. 3) and three rollers 3 on needle bearings, put on the trunnions of a three-spike hub.

Slots for rollers are made in the hinge body.

The three-spike hub is fixed on the drive shaft with a retaining ring 1, the rollers allow the hub to move in the grooves of the hinge body in the axial direction, so that the drive can lengthen or shorten to compensate for the mutual movements of the suspension and the power unit.

The tip of the internal joint housing with internal splines is put on the splined shank of the right side gear.

From axial movement on the pinion shank during suspension operation, the hinge body is fixed by an expanding spring 6 installed inside the hinge

The sealing of the hinge is provided by a cover 5, fixed with clamps 4 on the hinge body and on the drive shaft.

In the gearbox housing, the tip of the hinge housing is sealed with a toroidal rubber ring and a self-compressing oil seal.

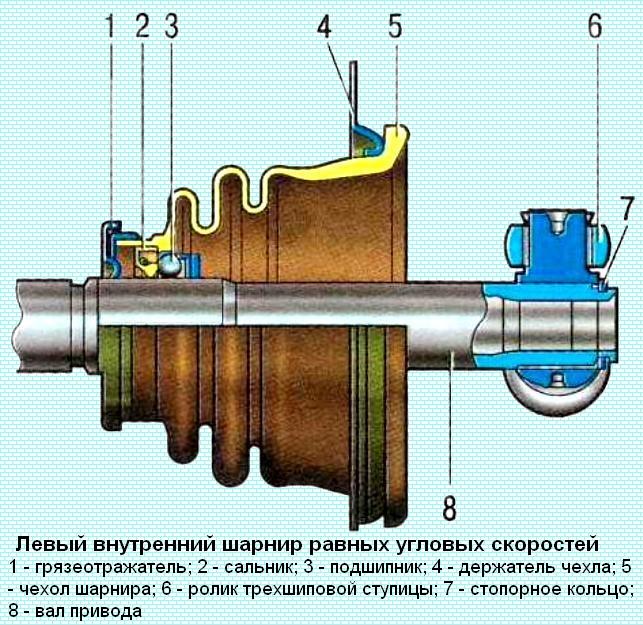

The left inner hinge consists of three rollers 6 (Fig. 4) on needle bearings, put on the trunnions of a three-spike hub.

The function of the hinge housing is performed by the left semi-axial gear of the gearbox of complex shape.

Its internal grooves for the rollers are made similar to the grooves of the body 2 (see Fig. 3) of the right inner hinge.

The three-spike hub is fixed on the shaft 8 (see Fig. 4) of the drive with a retaining ring 7.

The rollers allow the hub to move in the slots of the side gear in the axial direction, so that the drive can be extended or shortened to compensate for the mutual movements of the suspension and the power unit.

The sealing of the hinge is provided by a cover 5, which is fixedly fixed with the help of a holder 4 on the gearbox housing.

The drive shaft rotating inside the boot in bearing 3 is sealed with gland 2 installed under the boot in a removable unit common with the bearing.

To repair the right inner hinge, two repair kits are supplied as spare parts: a large one, which includes all the hinge parts, and a small one, similar to the outer hinge repair kit.

To repair the left inner joint, two repair kits are supplied as spare parts: a large one, which includes all parts of the joint, except for the side gear, and a small one, including the joint case and the bearing assembly with the oil seal.

To lubricate the outer hinges and the right inner hinge, a special lubricant with molybdenum disulfide "MOBIL CVJ 825 BLACK STAR" is used (supplied with a hinge repair kit, domestic analogue - SHRUS-4).

The splines of the inner joint shank are lubricated with "MOLYKOTE BR2" grease, and the left inner joint with gear oil for the gearbox.

The drive joints are very durable, their design life is almost equal to that of a car.

In operation, they are changed or repaired quite often due to the fact that they do not pay attention to the condition of the protective covers.

This kind of work is quite expensive and time-consuming. In order to save a lot of money, regularly check the condition of the protective covers of the hinges and replace them immediately in case of the slightest damage.

If water or dust gets into the hinge through a damaged cover, it will fail after several hundred kilometers.

Possible malfunctions of drives and solutions

Cause of malfunction - Remedy

Vibration while driving

Severe wear of the outer joint of the wheel drive - Replace the drive shaft assembly with the outer joint

Deformation of the wheel drive shaft - Also

Worn wheel drive inner joint rollers - Replace inner joint

Loose hub nut - Tighten or replace nut

Moving the car to the side

Worn or damaged inner joint race - Replace drive shaft with outer joint

Worn or damaged outer joint - Same

Damage or deformation of the wheel drive shaft - Replace the shaft

Loose hub nut - Tighten or replace nut

Grease leaking from hinges

Worn or torn outer or inner hinge protective boot - Inspect the hinge, replace if there is any play. Replace damaged cover and lubricant

Insufficient tightening of the clamps - Replace and securely tighten the clamps

Left inner joint shaft seal damaged - Replace left inner joint bearing assembly with seal

Noise, knock from the front wheel when the car is moving

Damage or deformation of the wheel drive shaft - Replace the drive shaft assembly with the outer joint

Beating of the front wheel drive shaft - Also

Loose hub nut - Replace or tighten nut

Knock when turning car

Severe wear of the outer joint of the wheel drive - Replace the drive shaft assembly with the outer joint