Cleaning the parts and inspecting the drive

The outer constant velocity joint should rotate with a slight effort without jerking and jamming, radial and axial play

If there are any, you need to replace the hinge

The inner hinge should move in the angular and axial directions with a slight effort, while jerking, jamming and radial play should not be felt.

Otherwise, you need to replace the hinge

Protective covers of the outer and inner hinges should not have cracks and breaks

The wheel drive shaft must not be deformed. Replace warped shaft

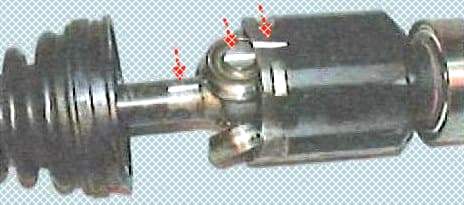

To replace the inner hinge or its cover, we disconnect the clamp of the protective cover with a screwdriver or pliers and remove the clamp

Clamps are disposable, we replace the clamps during assembly

We also remove the second clamp securing the cover

We move the protective cover from the hinge body, remove some of the lubricant from it and mark the position of the hinge relative to its body

Disconnect the inner hinge housing from the drive

Using a puller, we open the retaining ring of the hinge hub and remove the ring, removing it from the groove of the shaft

Remove the hub with rollers from the shaft splines

Remove the protective cover from the shaft

We wash all metal parts with kerosene until the old grease is completely removed

Before assembly, fill the cavity of the body and the cover of the inner hinge with grease in an amount of approximately 150 grams.

One hundred grams in a hinge and 50 grams in a case

In order not to damage the hinge cover during assembly, we wrap the splined part of the shaft with insulating tape

If there is no lubricant recommended by the factory, domestic SHRUS-4 lubricant can be used

We assemble and install the drive in reverse order