According to the engine maintenance regulations, it is necessary to check the engine for the absence of valve knock

Valve knock (heard in the upper part of the engine near the head cover).

Metal clatter against the background of a general muffled noise

It is well audible at low and medium speeds of the crankshaft from the side of the cylinder head above the valve locations.

If similar knocks are found, check the clearances in the valve drive

The gap between the end of the valve stem and the camshaft cam is designed to compensate for thermal expansion of the valve

With an increased gap, the valve will not open fully, and with a reduced gap, it will close completely

The clearance must be measured with a feeler gauge on a cold engine (at a temperature of +20º C) between the camshaft cam (the cam must be directed upwards from the tappet) and the valve tappet

The nominal gap for the intake valve is 0.19-0.29 mm, for the exhaust valve 0.38-0.48 mm.

The gaps are adjusted by selecting the thickness of the pushers

Spare parts are supplied with pusher sets with a thickness of 5.06 to 5.74 mm through 0.02 mm

The valves located on the left side of the engine (closer to the front of the car) are exhaust valves, on the right side are intake valves

To check and adjust the valves, remove the cylinder head cover, as described in the article "How to replace the cover and cylinder head gasket 2AZ-FE Toyota Camry"

Set the piston of the first cylinder to the TDC position of the compression stroke, as described in the article "How to set the TDC of the first cylinder of the 2AZ-FE engine"

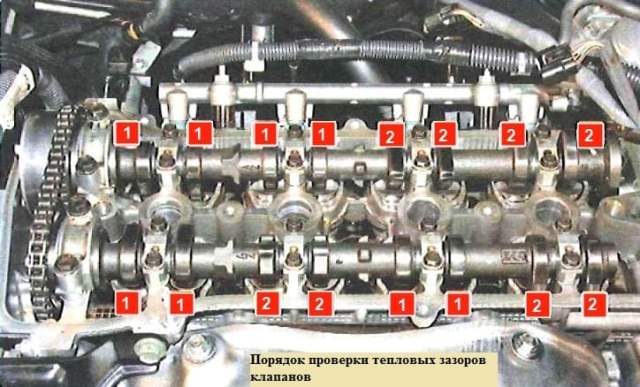

We measure with a feeler gauge the gaps between the camshaft cams and the valve lifters, marked with the number 1 in Figure 2

Measure and record measured gaps

After that, turn the crankshaft one revolution (360º), and measure the gaps marked with the number 2 in Figure 2

Write down the measured clearances

It is necessary to replace the tappets of those valves whose clearances differ from the nominal values

After measuring all the gaps, set the piston of the first cylinder to the TDC position of the compression stroke

Removing the camshafts (described in the article " How to replace the camshafts of the 2AZ-FE Toyota Camry engine”)

We remove the valve lifter from the cylinder head socket, which needs clearance adjustment, and record its thickness (it is indicated on its reverse side)

The number stamped on the valve lifter is the tappet thickness.

Only two digits after the decimal point are applied (for example, "44" means the thickness of the pusher is 5.44 mm)

We calculate the thickness of the new pusher using the formula (all values in mm):

H = B + A - C

- Where A is the measured gap;

- B is the thickness of the old pusher;

- С - nominal gap;

- Н is the thickness of the new pusher.

For example (for the intake valve): A = 0.31 mm, B = 5.42 mm, C = 0.24 mm, then H = 5.42 + 0.31 - 0.24 = 5.49 mm

Within the clearance tolerance (+0.05 mm), we select the pusher closest in thickness 5.50 mm

Install the new pusher in place

In the same way, we replace the tappets of all valves that require clearance adjustment

We install the camshafts, but we do not install the timing chain yet

Turning the camshafts by the hexagons made on them, we measure the resulting gaps with a feeler gauge.

If the gaps differ from the nominal values, repeat the adjustment

If all the gaps correspond to the nominal values, we turn the camshafts so that the cams of the valve drive of the first cylinder are directed upwards

Install the timing chain and all removed parts in reverse research