Replacing the cylinder head cover gasket

To complete the task, you will need tools: wrenches for 14, 13, socket heads for 10, 14, 19 and screwdrivers

We prepare the car for the task and remove the negative terminal from the battery

Remove the decorative engine cover

Disconnect the hoses of the crankcase ventilation system from the branch pipes of the head cover

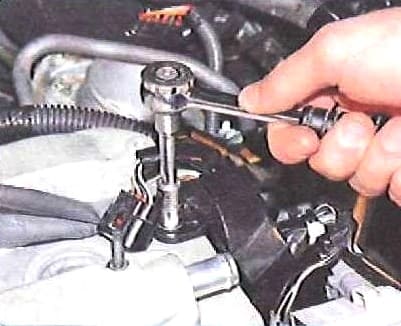

Remove ignition coils

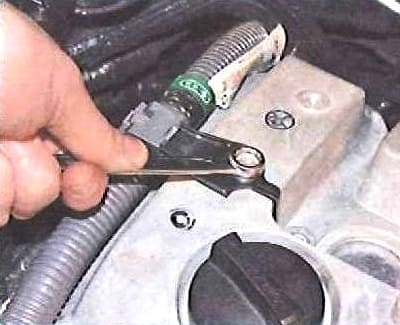

We unscrew the bolt securing the wire holder of the engine management system, and take the wiring harness to the side

We also unscrew the bolt securing the engine compartment wiring harness holder, and move the harness to the side

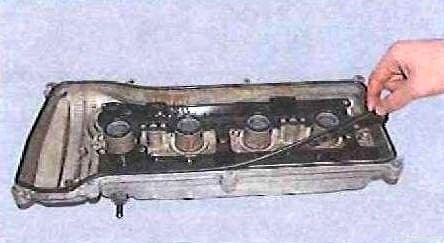

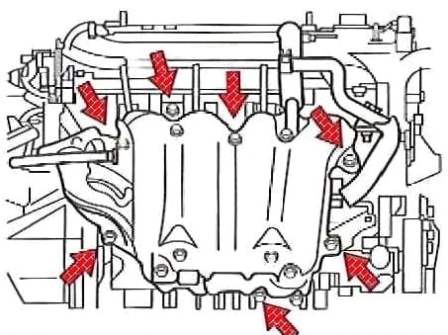

We unscrew the eight bolts securing the cylinder head cover and remove the cover

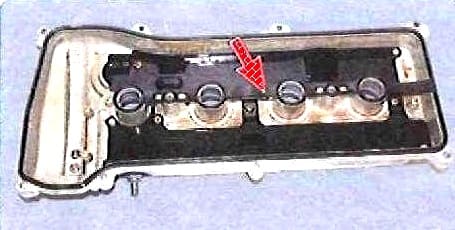

We take out the gasket and the sealing rubber gasket of the candle holes from the grooves in the cover

We clean the groove of the cover and the mating surface of the cylinder head from oil residues

Install new cylinder head cover gaskets and parts in reverse order

Replacing the cylinder head gasket

Reducing the pressure in the power system

Remove the negative wire from the battery

Remove the decorative engine cover

Disconnect the hoses of the crankcase ventilation system from the branch pipes of the head cover

Remove the front right wheel liner

Remove the engine mudguard

Drain the engine oil from the crankcase

Draining the coolant

Remove the hood

Remove the two clips and remove the windshield wiper trim

Remove the battery

Unscrew the bolts and remove the battery shelf

Remove the air filter

Remove the throttle body

Remove the fuel rail

Disconnect the vacuum brake booster hose from the intake manifold pipe

Disconnect the wire block from the hydraulic valve for changing the phases of the gas distribution mechanism

We unscrew the five bolts and two nuts securing the intake manifold, and remove it

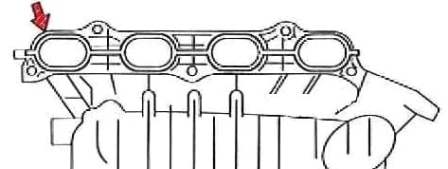

Remove the intake manifold gasket

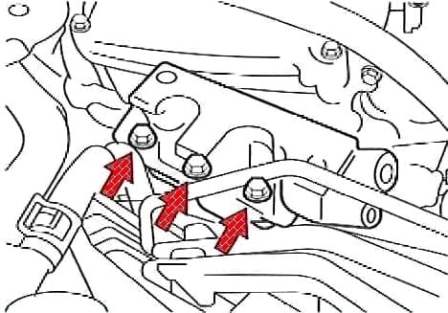

We unscrew the two mounting bolts bracket to cylinder head and support bracket

Remove the thrust of the longitudinal movement of the power unit

We install the jack through a wooden spacer under the gearbox housing and raise the power unit, thereby unloading its support

We unscrew the three screws and remove the bracket for fastening the right support of the power unit

Remove the accessory drive belt

Remove the generator

Remove the O-ring from the dipstick tube

Remove the collector

Remove the timing chain

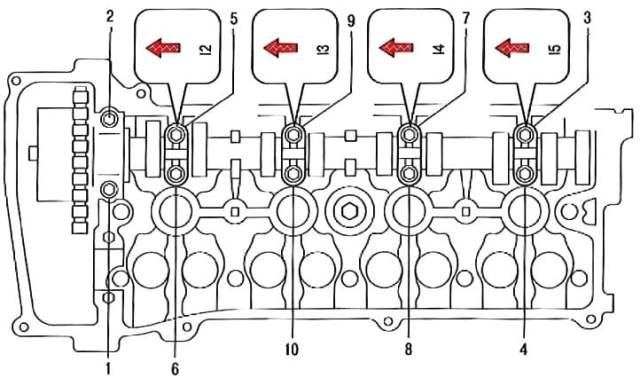

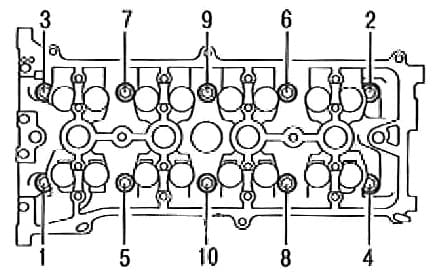

We unscrew the bolts of the intake camshaft bearing caps from the cylinder head, in the sequence shown in the figure

Remove the bearing caps and take out the camshaft

Disconnect the block of wires from the hydraulic phase change valve

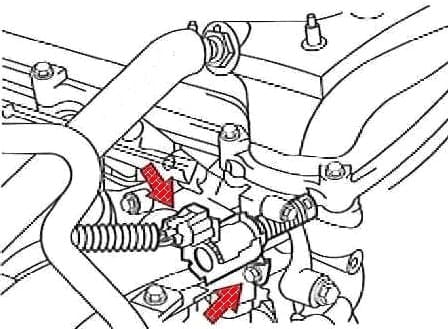

We unscrew the bolt and remove the hydraulic valve of the phase regulator

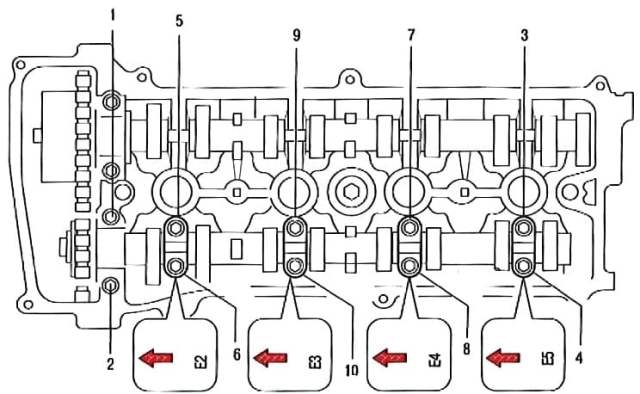

We unscrew from the cylinder head, in the sequence indicated in the figure, the bolts securing the bearing caps of the exhaust camshaft

Remove the bearing caps and take out the camshaft

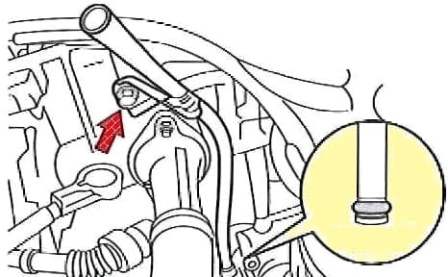

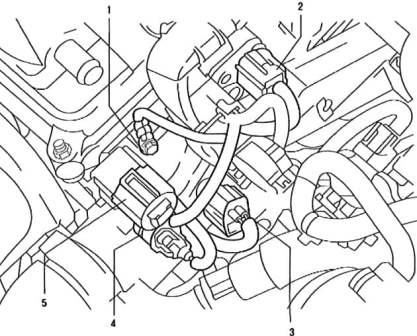

Unscrew the bolt and disconnect the tip of the wire "-" 1

Disconnect the wire blocks from the camshaft position sensor 2, coolant temperature sensor 5, oil pressure sensor 4 and from the radio tuning capacitor 3

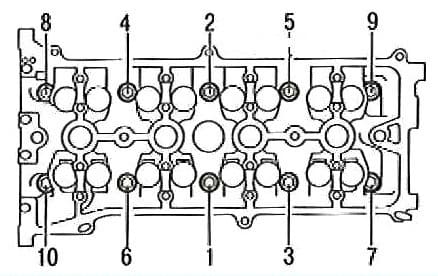

We unscrew the cylinder head bolts in the sequence shown in the figure, remove them together with the spring washers and remove the cylinder head

Remove the cylinder head gasket

It is advisable to remove the head with two people, the head is quite heavy

We clean the mating surfaces of the cylinder head, remove oil from the threaded holes in the block for the head bolts

Checking the block head for warping

To do this, we put the ruler with an edge on the surface of the head, first in the middle along, across, and then along the diagonals and with a probe we measure the gap between the plane of the head and the ruler

Replace the cylinder head if the gap exceeds 0.1 mm

Install the cylinder head in reverse order, taking into account the following:

- - remove from the threaded holes of the fastening bolts oil or coolant that got there when the head was removed;

- - install a new block head gasket, gasket reuse is not allowed

- - lubricate the bolts with engine oil

- - we tighten the bolts on a cold engine in the order shown in the figure, in two stages:

- - stage 1 - tighten the bolts with a torque of 70 Nm;

- - stage 2 - tighten the bolts at an angle of 90º

- - install camshafts

Install parts in reverse order

After installing the camshafts and the timing chain, we check and, if necessary, adjust the clearances in the valve drive