The oil pump is removed for replacement when its supply decreases, causing a constant drop in oil pressure in the engine lubrication system.

The pump is also removed when oil leaks through the seal of the mating surfaces of the pump housing and cylinder block

We install the car on a lift or an inspection ditch and disconnect the negative battery terminal

Drain the oil from the engine oil sump, as indicated in the previous article

Set the piston of the first cylinder to the TDC position of the compression stroke, as described in the article "TDC setting"

Remove the timing chain

Remove the timing chain drive sprocket from the crankshaft

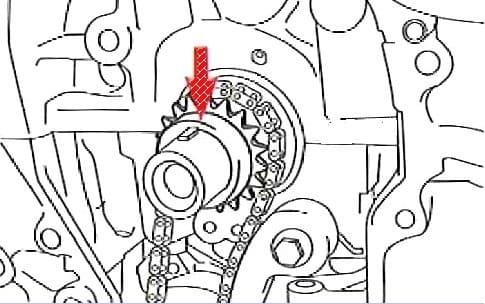

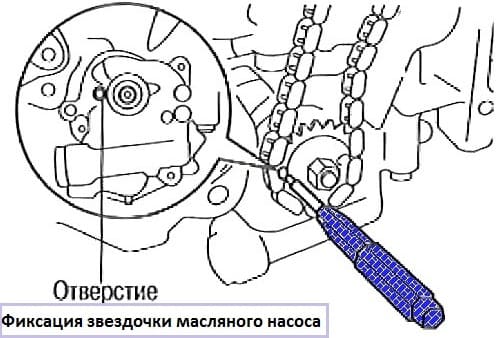

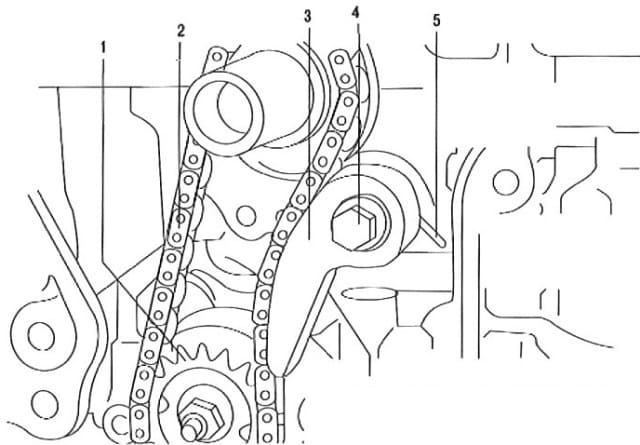

We turn the engine crankshaft counterclockwise by 90º approximately until the holes in the sprocket and the oil pump housing are aligned, after which we fix the sprocket from turning with a suitable rod with a diameter of 4 mm and unscrew its fastening nut

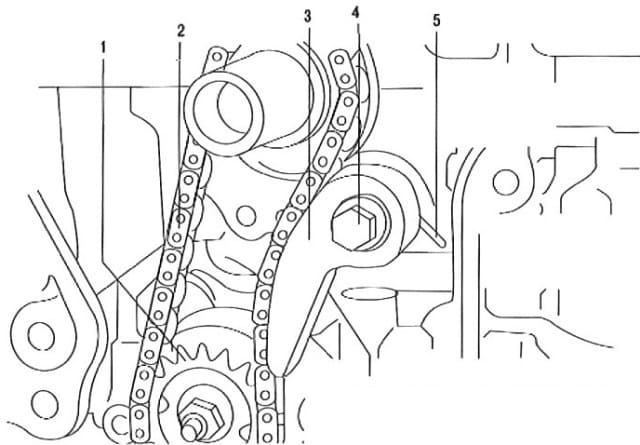

We unscrew the bolt 4 (Fig. 3) and remove the tensioner 3 of the oil pump drive chain with spring 5, the oil pump drive chain 2 and the oil pump sprocket 1

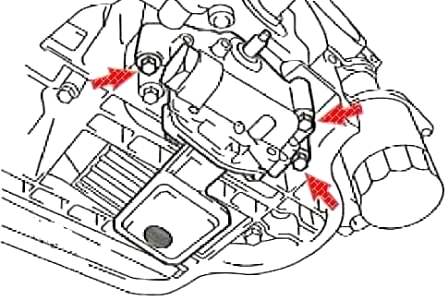

We unscrew the three bolts (shown by arrows) securing the oil pump to the cylinder block

We pry the pump with two screwdrivers and remove it from the mounting bushings in the cylinder block

Remove the sealing gasket installed under the flange of the oil pump housing

The body gasket must be installed new

Each time the oil pump is removed, flush the oil receiver screen with gasoline or kerosene

We install the pump with a seal and tighten the mounting bolts to a torque of 19 Nm

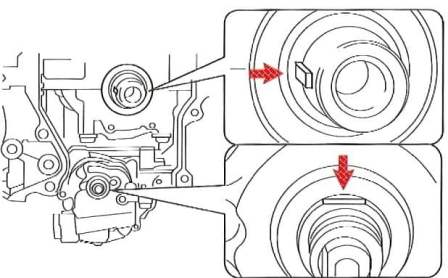

Install the crankshaft and oil pump shaft in the position shown in Figure 5

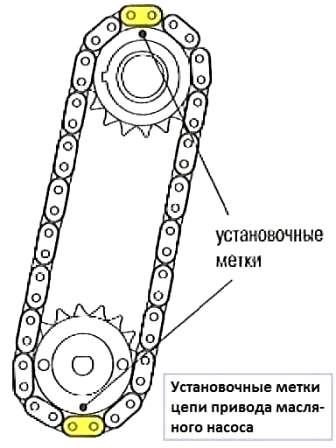

Install the oil pump drive chain with sprockets by aligning the alignment marks as shown in Figure 6

Tighten the oil pump sprocket nut by hand

Install chain tensioner 3 with spring 5.

Tighten bolt 4 with a torque of 12 Nm

Fixing oil pump sprocket in the manner described above, and tighten its fastening nut to a torque of 30 Nm

Turn the crankshaft clockwise approximately 90º so that the key at its end is in the upper position

We install all the removed parts in the reverse order and fill the engine with oil

When installing a new oil pump, it is recommended to change the oil filter