In the article, we will consider the replacement of sensors and switches

We discussed the replacement of engine control system sensors in the article - Removing and installing elements of the Toyota Camry engine control system

Oil pressure drop sensor replacement

The oil pressure warning light sensor is screwed into the cylinder block wall at the rear (next to the coolant temperature sensor)

Remove the decorative engine cover

Disconnect the negative battery terminal

Remove the air filter with the air intake

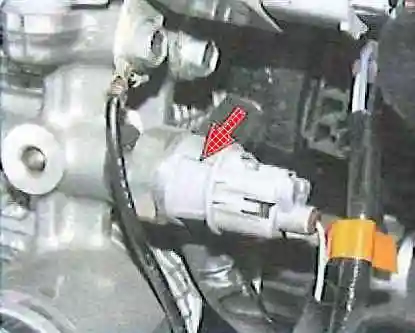

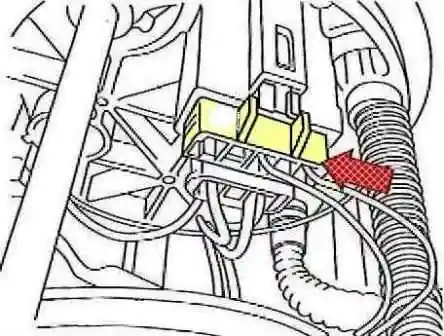

Squeeze the latches and disconnect the wire block from the sensor

Unscrew the sensor from the cylinder block

Install the oil pressure drop sensor in reverse order

Checking and replacing the fuel gauge sensor

Fuel gauge sensor installed in the fuel module

We reduce the fuel pressure, as indicated in the article - Checking and reducing the fuel pressure of the 2AZ-FE engine of a Toyota Camry car

Disconnect the negative battery cable

We remove the fuel module, as described in the article - Removing and disassembling the fuel module of a Toyota Camry car

Disconnect the fuel gauge sensor wire block from the fuel module flange

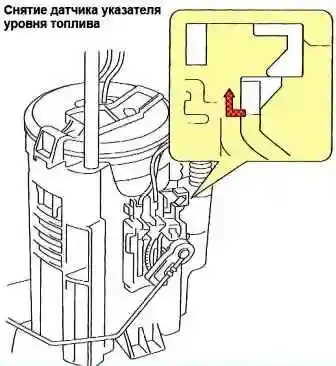

Unfasten the latch and remove the sensor from the fuel module body

To check the sensor, we connect the tester in ohmmeter mode to the terminals "2" ("S") and "3" ("FE") of the sensor

We measure the resistance of the sensor at the lower position of the lever with the float. The resistance should be 405.5-414.5 ohms

Raise the lever with the float to its highest position - the resistance should decrease to 13.5-16.5 Ohm

If the resistance of the sensor differs from the given values, then the sensor is defective and needs to be replaced

Install parts in reverse order

Checking and replacing the automatic transmission shaft speed sensors

Torque converter turbine wheel speed sensors and gearbox output shaft speed sensors are installed in the upper part of the gearbox housing

Remove the battery and air filter with air intake

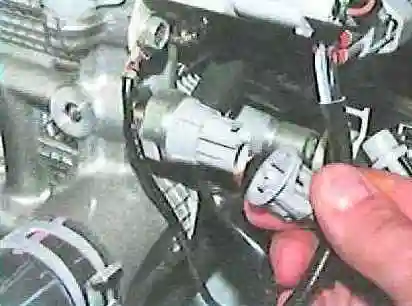

Squeeze the latches and disconnect the wire block (B) from the sensor to be replaced

We unscrew the bolt (A) and remove the sensor from the hole in the gearbox housing

To check the sensor, we measure the resistance between the contacts.

At +20º C, the resistance should be 560-680 ohms. If the resistance is different, then the sensor is defective

If the sealing ring of the sensor is damaged, then we replace it

Install the sensor in reverse order

Replacing the automatic transmission selector position sensor

The sensor is installed in the lower part of the gearbox housing (in front of the vehicle)

We prepare the car and disconnect the negative battery terminal

Remove the air filter with the air intake

If we install the same sensor, then before removing it, you need to mark the position of the sensor relative to the gearbox housing

Unscrew the nut 1 and disconnect the cable from the gear lever 2

Unscrew the nut 3 and remove the gearshift lever 2 from the shaft

We bend the antennae of the lock washer 5 and unscrew the lock nut 6. Remove the lock washer from the shaft

Squeeze the latches and disconnect from the position sensor of the automatic transmission selector block 7 of the wiring harness

Remove the sensor from the gearbox by unscrewing its fastening bolts 4 and 8

Installation

We install the selector position sensor on the gearbox without finally tightening the bolts 4 and 8

Connect the block of wires 7 to the sensor

Install a new lock washer 5 and tighten the locknut 6 to 6.9 Nm

Install the lever 2, tighten the nut 3 to a torque of 13 Nm and bend the tab of the lock washer.

Raise the lever up to the stop, and then lower it down two clicks

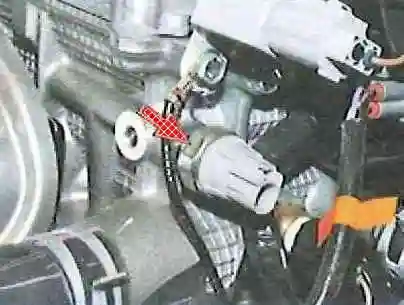

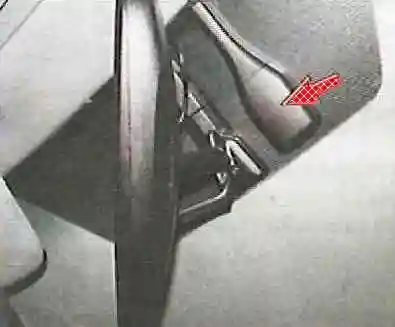

Without changing the position of the lever, turn the sensor body so that the tab of the lock washer (shown by the arrow) is directed along the neutral line applied to the sensor body (highlighted in red in the photo).

In this position, tighten the sensor mounting bolts

Install all removed parts in reverse order

Make sure the engine starts only in the "N" and "P" positions of the selector, and the reverse light turns on in the "R" position and does not turn on in other positions

If malfunctions are found, we repeat the adjustment of the position of the automatic transmission selector position sensor

Replacing the brake light switch

The brake light switch is mounted on the brake pedal bracket

Disconnect the negative battery terminal

Remove the lower decorative shield

Disconnect the wiring harness from the brake light switch and unscrew the switch from the brake pedal bracket

Installation

We screw the brake light switch into the bracket until the end of the working part of its body stops against the brake pedal buffer, and then unscrew it a quarter of a turn

If the brake light switch is installed correctly, with the brake pedal released, there should be a gap of 1.5-2.5 mm between the end of the threaded part of the switch and the brake pedal buffer

Install all removed parts in reverse order

Replacing the automatic wiper control sensor

An automatic wiper control sensor (rain sensor) is installed on the inside of the windshield next to the rearview mirror

Disconnect the negative battery terminal

Remove the sensor cover

We pull out the stopper of the sensor housing and disconnect the sensor from the mounting bracket

Remove the wiper automatic control sensor by disconnecting the wire block from it

Install parts in reverse order

Replacing doorway light switches

The doorway light switches are installed in the holes in the door pillars of the body

Disconnect the negative battery terminal

We unscrew the fastening screw and remove the doorway illumination switch from the hole in the pillar

Disconnect the wiring harness and remove the switch

Install the switch in reverse order

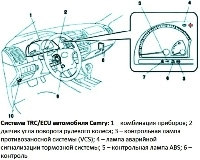

Immobilizer

The immobilizer consists of an electronic control unit, an antenna unit in the ignition lock (transponder ring), keys and a signal lamp in the display unit

The immobilizer control unit is installed on the left under the instrument panel and connected to the electronic engine control unit

When the ignition is turned on, the immobilizer control unit receives a password code from the antenna unit, which is compared with the information stored in the computer memory

Based on the result of the code analysis, the immobilizer control unit decides on the possibility of starting the engine and transmits the appropriate command to the engine controller

If the immobilizer electronic unit is replaced, it is necessary to perform the ignition key learning procedure, otherwise it will not be possible to start the engine

Replacing the mirror control unit, the headlight electrocorrector control and the headlight washer switch

Remove the decorative lower shield and instrument panel trim to the left of the steering column

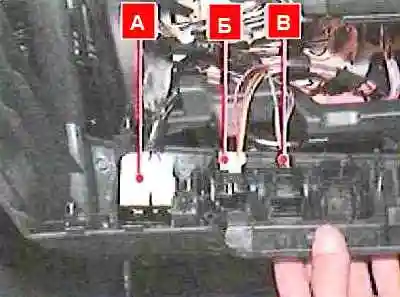

To replace the rear-view mirror control unit, the headlight electrocorrector control or the headlight washer switch, disconnect the wire blocks A, B and C from them, respectively, by squeezing the clamps

Squeeze the latches and remove the element to be replaced from the hole in the instrument panel lining

Hazard switch replacement

Disconnect the negative battery terminal

Using a puller, we release the seven latches and remove the central air duct panel with deflectors from the instrument panel

Disconnect the wire block from the alarm switch and remove the switch, releasing the four latches

Install parts in reverse order