An external sign of wear on the valve stem seals is the short-term appearance of blue smoke from the exhaust pipe after starting the engine, as well as when braking the engine after a long drive under load

In this case, constant smoking is usually not observed. Indirect signs are increased oil consumption in the absence of external leaks and oily spark plug electrodes.

It is possible to replace valve stem seals without removing the cylinder head from the engine.

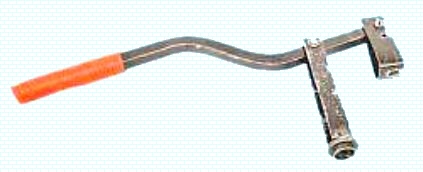

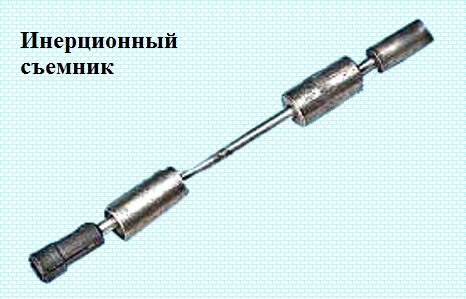

You will need: all the tools needed to remove the cylinder head cover (see "Replacing the Renault Logan valve cover gasket"), as well as a "12" wrench, tweezers (or a magnetized screwdriver) to remove crackers from the valve spring plates , a tool for compressing valve springs, a tong or inertial oil seal remover.

The puller shown has a mandrel on the other end to press on the caps.

In the absence of such a puller, you will need pliers to remove the caps and a mandrel of a suitable diameter to press them onto the valve guides.

Disconnect the wire from the negative terminal of the battery.

Remove all spark plugs.

Remove the cylinder head cover (see "Replacing the cylinder head cover gasket").

Set the piston of the 1st cylinder to the TDC position of the compression stroke.

In this position of the crankshaft, the pistons of the 1st and 4th cylinders are at TDC. This makes it possible to dry out the valves of these cylinders without the risk of dropping them into the cylinder.

To set the piston of the 1st cylinder to the TDC position of the compression stroke, the removal of the top cover of the timing belt is required (to gain access to the alignment marks on the camshaft pulley and on the head of the block), which entails laborious preliminary operations to remove the right suspension mounts of the power unit.

With an accuracy sufficient to set the pistons of the 1st and 4th cylinders to the TDC position when replacing the valve stem seals, the camshaft can be set) to the required position, controlling it visually.

When turning the crankshaft, the camshaft must be installed so that the heels of the rocker arms of the drive of both valves of the 1st or 4th cylinders rest on the back of the camshaft cams, and the rocker arms can be moved by "swaying" within the gap.

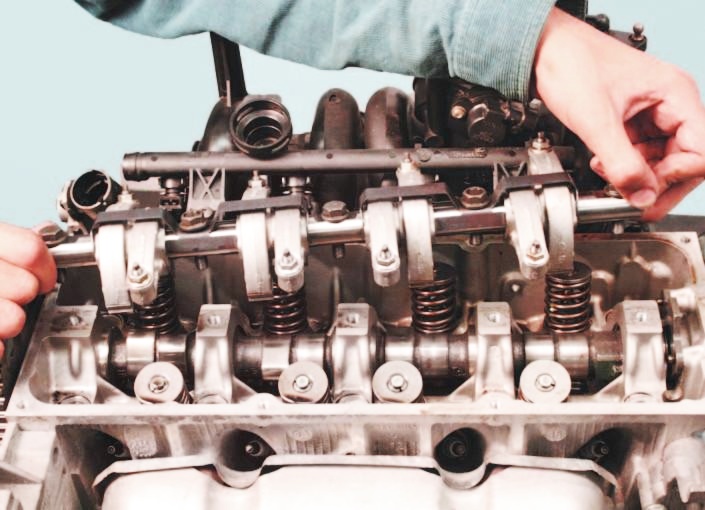

Evenly loosening the five bolts securing the valve rocker arm axle, remove the bolts from the holes in the block head and the axle

Note that the bolts have different head shapes.

Install the bots when reassembling in their original places.

Remove the axle assembly with rocker arms.

If you do not intend to replace the rocker arms, their axle and camshaft, do not remove the rocker arms from the axle in order to install them in their original places during assembly.

Install the valve spring compressor by screwing the valve rocker axle bolt into one of the holes in the head of the block and hooking the tool onto this bolt.

Compress the spring with the tool valve and remove two crackers from the spring plate with tweezers or a magnetized screwdriver.

Then remove the fixture.

Remove the spring cap and valve spring.

The valve spring support washer does not need to be removed, as it does not interfere with the replacement of the valve stem seal.

Press the valve stem seal off the valve guide.

To do this, install the collet of the inertial oil seal remover on the cap and sharply hit the collet sleeve with the striker.

Then, just as sharply hit the handle of the device with the striker, thereby pressing the cap off the sleeve

If an inertial cap remover is not available, remove the cap with a special tong-type remover or pliers, applying force straight up and without turning the cap so as not to damage the valve guide.

Do not remove the cap by prying it on both sides with screwdrivers.

The guide sleeve, on which the cap is put on, is made of sintered metal, and its edge breaks off easily.

Before installing new valve stem seals, we recommend that you remove the springs from them, otherwise the caps can be damaged when they pass through the grooves for crackers on the valves.

If a plastic mounting sleeve is included with the new caps, the springs do not have to be removed.

In this case, put the sleeve on the valve stem.

Lubricate the inner surface of the valve stem seal with engine oil and slide the cap over the valve stem to the guide sleeve

Install the mandrel for pressing the cap.

With light blows of the striker against the mandrel, press the cap in until it stops

In the absence of a special device, you can select a cylindrical mandrel of a suitable diameter and press the cap through it with light hammer blows on the mandrel.

You can use the long head from the toolbox as a mandrel.

Select a head with 12 faces and a chamfer inside the hole so that the contact of the head with the cap is in a solid circle.

Remove the valve guide from the valve stem or put a spring on the cap if it was removed.

Install the spring and valve disc in the reverse order of removal.

Install the cotters with the tool so that they fit into the grooves of the valve stem.

After installing the crackers, hit the end of the valve with a hammer through the metal rod so that the crackers sit in place

If the skewed crackers remain unfixed, when the engine is started, the “dry” valve will fall into the cylinder, which will lead to a serious engine failure.

Similarly, replace the valve stem seals of the second valve of the 1st cylinder and two valves of the 4th cylinder.

Turn the crankshaft half a turn so that the pistons of the 2nd and 3rd cylinders are at TDC, and replace the valve stem seals of the remaining valves

After installing the valve rocker shaft assembly with rocker arms on the engine, check and, if necessary, adjust the clearances in the valve drive (see "Adjusting clearances in the valve drive").

Install all removed parts in the reverse order of removal.