Toyota Camry is equipped with two independent braking systems: working and parking

The first, equipped with a hydraulic drive, provides braking when the car is moving, the second slows down the car in the parking lot.

The working system is two-circuit, with a diagonal connection of the brake mechanisms of the front and rear wheels.

One hydraulic circuit ensures the operation of the right and front and left rear brakes, the other - the left front and right rear.

If one of the circuits of the service brake system fails, the second circuit is used to stop the car with sufficient efficiency.

A vacuum booster is included in the hydraulic drive (on parts of the production of cars - with a mechanical emergency braking system).

In addition, the car is equipped with electronic active safety systems: anti-lock braking system (ABS), brake force distribution system, and, on special order, traction control (TRC) and Vehicle Stability Control (VSC).

For vehicles equipped with a vacuum brake booster without a mechanical emergency braking system, an electronic emergency braking system (BA) is installed.

The parking brake system has a cable drive to the rear wheel brakes.

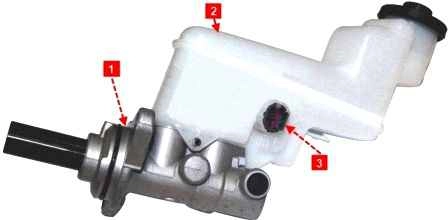

The tandem hydraulic brake master cylinder 1 consists of two separate chambers connected to independent hydraulic circuits.

The first chamber is connected to the right front and left rear brakes, the second to the left front and right rear.

A tank 2 is installed on the main cylinder through rubber connecting bushings, the internal cavity of which is divided by partitions into two compartments.

Each compartment feeds one of the brake master cylinder chambers.

On vehicles with a manual transmission, there is also a compartment in the reservoir for powering the clutch release master cylinder.

When you press the brake pedal, the pistons of the main brake cylinder begin to move, the working edges of the cuffs block the compensation holes, the chambers and the reservoir are separated, and the displacement of the brake fluid begins.

A 3rd brake fluid level sensor is installed in the upper half of the reservoir body.

If the fluid level falls below the permissible level, the warning light for a malfunctioning brake system lights up in the instrument cluster.

A vacuum booster installed between the pedal mechanism and the main brake cylinder, when braking due to rarefaction into the engine intake pipeline through the rod and piston of the first chamber of the main cylinder, creates an additional force proportional to the force from the pedal.

A non-return valve is installed in the hose connecting the vacuum booster to the intake pipe.

It holds the vacuum in the booster as it drops down the intake pipe and prevents the air-fuel mixture from entering the vacuum booster.

On some of the produced cars, the mechanical emergency braking system "BA" is included in the vacuum booster.

In emergency situations, drivers, especially inexperienced ones, often panic and do not press the brake pedal hard enough.

The "BA" system perceives a sharp press on the brake pedal as an emergency braking signal, and applies the maximum possible force to the master cylinder rod.

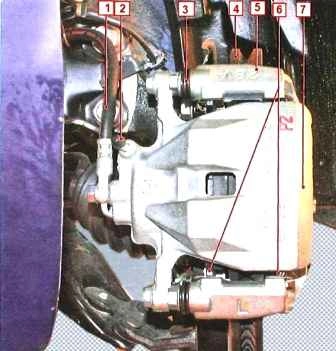

The brake mechanism of the front wheel is disc, ventilated, with automatic adjustment of the gap between pads 6 and disc 4, with a floating caliper.

The movable bracket is formed by a caliper 7 with a single-piston working cylinder.

The 5 shoe guide is bolted to the steering knuckle.

The movable bracket is attached with guide pins 3 screwed into the threaded holes of the shoe guide.

The guide pins are grease lubricated and protected by plastic bushings.

A piston with a sealing ring is installed in the cavity of the working cylinder.

Due to the elasticity of this ring, the optimal clearance between the pads and the fan is maintained disc.

When braking, the piston, under the influence of fluid pressure, presses the inner pad against the disc, under the influence of the reaction force, the caliper moves on the fingers and the outer pad is also pressed against the disc, while the force pressing the pads is the same.

When releasing the piston, due to the elasticity of the sealing ring, it is removed from the pad, as a result, a small gap forms between the pads and the disc.

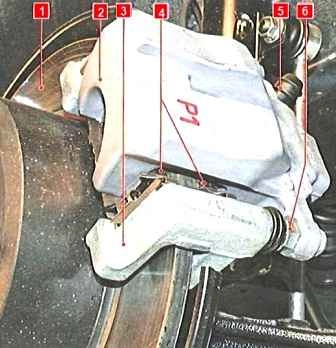

Brake rear wheel disc, with automatic clearance adjustment

The 4 brake pads are actuated by a single hydraulic working cylinder.

The optimal clearance between the drum and the pads is maintained according to the same principle as for the front wheel brakes.

The rear wheel disc service brake is combined with the parking brake drum mechanism

The inner cavity of the brake disc also serves as the parking brake drum.

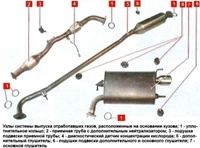

The mechanically actuated parking brake consists of a pedal (on vehicles with a manual transmission - a lever), a front cable with an adjusting device, two rear cables and mechanisms on the rear wheels.

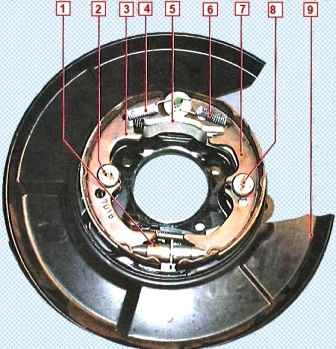

On the shield 9 of the parking brake mechanism, brake pads 3 and 7, tightened by springs, are installed

The rear ends of the rear cables are connected to the expansion levers mounted on the rear shoes of the 7 parking brakes.

When moving the expanding levers, they move the front brake shoe 3 through the spacer bar until it stops in the brake drum, made in one piece with the disc, and then, having received a hard stop, press the rear shoe against the drum.

The optimal clearance between the shoes and the drum when assembling the brake mechanism is set manually using the adjusting device 1.

The parking brake is low maintenance.

During the current repair, check the degree of wear of the sector teeth and pawls. Replace excessively worn parts.

Sheaths or wires of cables should be replaced with new ones if they are broken.

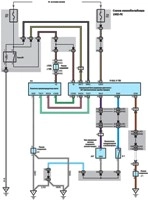

The anti-lock braking system consists of wheel speed sensors, a brake light switch, a hydro-electronic control module and a signal lamp in the instrument cluster.

In addition, the anti-lock braking system is equipped with a self-diagnostic system that detects component malfunctions.

ABS is used to regulate the pressure in the brake mechanisms of all wheels when braking in difficult road conditions, which prevents the wheels from blocking.

The ABS system provides the following benefits:

- - obstacle avoidance with a higher degree of safety, including during emergency braking;

- - reduction of the braking distance during emergency braking while maintaining roadholding and controllability of the car, including when turning.

In the event of a system failure, diagnostics and maintenance functions are provided in case of system failures.

The hydroelectronic control module receives information about vehicle speed, direction of travel and road conditions from wheel speed sensors.

After the ignition is turned on, the ABS module supplies voltage to the sensors.

Sensors use the Hall effect and generate an output signal in the form of rectangular pulses.

The signal changes in proportion to the rotational speed of the pulse ring of the sensor built into the front hub bearing seal and directly into the rear hub

Based on this information, the module determines the optimal wheel braking mode.

The following modes of operation of the anti-lock braking system are distinguished:

- - normal braking mode.

During normal braking, the solenoid valve is de-energized, the inlet valve is open, the outlet valve is closed.

When you press the brake pedal, brake fluid under pressure is supplied to the working cylinder through an electromagnetic valve and actuates the wheel brakes.

When the brake pedal is released, the brake fluid returns to the brake master cylinder through the inlet and check valves;

- - emergency braking mode.

If the wheel locks up during emergency braking, the module will issue a command to the solenoid valve to reduce the supply of brake fluid, then voltage is applied to each solenoid valve

The inlet valve closes and the brake fluid supply from the master cylinder is shut off; the outlet valve opens, and the brake fluid flows from the working cylinder to the master cylinder, and then to the reservoir, which causes a decrease in pressure;

- - pressure maintenance mode.

When the pressure in the working cylinder decreases to the maximum, the module issues a command to the solenoid valve to maintain brake fluid pressure, voltage is applied to the inlet valve and not to the outlet valve.

At the same time, the inlet and outlet valves are closed, and the brake fluid does not leave the working cylinder;

- - pressurization mode.

If the module determines that the wheel is not locked, it de-energizes the solenoid valve. Voltage is not applied to the solenoid valves, the brake fluid through the inlet valve enters the working cylinder, in which the pressure increases.

The ABS hydroelectronic module and wheel speed sensors are also used in other active safety systems.

So, in the brake force distribution (EBD) system, the module evaluates the change in the load on each wheel according to the signals from the wheel speed sensors and accordingly changes the pressure in the brake pipelines.

In the traction control system (TRC) ET01, the same module, using speed sensors, monitors wheel slip and, if necessary, slows down the slipping wheel, raising the pressure in its brake pipeline.

In addition, in this case, the hydro-electronic module sends a signal to the engine control unit to reduce torque. When the "TRC" is triggered, the "SUP" warning lamp flashes in the instrument cluster.

In the electronic emergency braking system (BA), a pressure sensor installed in the hydroelectronic module detects a sharp pressing of the brake pedal.

In this case, the module creates the maximum possible braking force in the brake mechanisms (emergency braking mode).

In the Vehicle Stability Control (VSC), the hydro-electronic module analyzes the signals from the wheel speed sensors, as well as the steering angle sensor and the yaw rate and lateral acceleration sensor.

According to the signals of the sensors, the hydroelectronic module determines the occurrence of a drift of the front axle or a skid of the rear axle of the car.

In the event of a front axle drift, the module corrects the vehicle's trajectory by braking both wheels on the inside of the turn and sends a signal to the engine control unit to reduce torque.

When the rear axle skids, the trajectory is corrected by braking the front wheel from the outside of the turn, and, if necessary, both rear wheels.

When the VSC system is activated, a buzzer will sound and the "SUP" indicator lamp will flash in the instrument cluster.

The VSC steering angle sensor is installed in the steering column, and the yaw rate and lateral acceleration sensor is located under the floor tunnel lining.

Special equipment and accessories are required for diagnostics and repair of electronic active safety systems.

Therefore, in case of failure, contact a specialized service station.

The hydraulic brake system is integrated into a single unit with metal pipes and hoses.

The system is filled with a special brake fluid of at least DOT-3 class, which must be replaced periodically.

Some drivers, in an effort to reduce wear on the parking brake cables, try to use it less often.

Such "economy" leads to the opposite result: the cable, rarely moving in the shell, gradually loses its mobility, it jams, as a result, the cable breaks. Therefore, use the parking brake whenever necessary.

The free travel of the brake pedal with the engine off should be approximately 1-6 mm.

Too little free play indicates an incorrect initial setting of the brake pedal or seizure of the working cylinder, causes increased fuel consumption and accelerated wear of the brake pads.

Too much free play is a sign of excessive clearances in the pedal mechanism or a leak in the hydraulic drive of the brake system.

If the free play decreases when you repeatedly press the pedal, i.e. it becomes "harder" - there is air in the system. If full hod pedal starts to increase, the system is leaky.

If the brake pedal starts to vibrate when braking, the brake discs are most likely warped. Unfortunately, in such a situation, they only need to be changed, and both at once.

Periodically appearing and disappearing vibration of the pedal during sudden braking of the car accompanies the operation of the anti-lock brake system and is not a sign of a malfunction.

If the car starts to pull to the side when braking, check the slave cylinders: they may need to be replaced.

If there is a knock in the suspension that disappears when braking, check the tightness of the caliper mounting bolts.

After replacing the brake pads, be sure to press the brake pedal several times before starting to move - the pistons in the working cylinders must fall into place.

Possible malfunctions of the brake system and methods of elimination

Increased brake pedal travel:

Leakage of brake fluid from working brake cylinders - replace failed brake cylinders, wash and dry pads, discs and drums;

Air in the hydraulic drive of the brakes - remove the air by pumping the hydraulic drive;

The rubber sealing rings in the main brake cylinder are damaged - replace the cylinder;

The rubber hoses of the hydraulic brake drive are damaged - replace the brake hoses and bleed the system;

Increased brake disc runout (greater than 0.05 mm) - grind or replace the disc if the thickness of the brake discs of the front wheels is less than 25.0 mm and the rear wheels are less than 8.5 mm

Insufficient braking performance:

Oiling the lining of the brake pads - wash and dry the pads;

Jamming of pistons in working cylinders - eliminate the causes of jamming, replace damaged parts;

Complete wear of the brake pads - replace the brake pads;

Brake overheating - stop immediately and let the brakes cool down;

Use of poor quality pads - use original pads;

Violation of the brake pedal adjustment (the distance from the pedal pad to the floor is less than normal) - adjust the position of the brake pedal, determine the cause of the increase in full travel and replace the damaged parts;

Violation of the tightness of one of the circuits (accompanied by pedal failure) - replace damaged parts, bleed the system;

The protrusion of the vacuum brake booster rod has been reduced - adjust the position of the rod;

ABS malfunction - ABS needs to be checked

Incomplete release of all wheels:

- - there is no free play of the brake pedal - adjust the position of the pedal;

- - the protrusion of the brake booster rod is increased - adjust the vacuum booster rod;

- - swelling of the rubber seals of the main cylinder due to the ingress of gasoline, mineral oils, etc. into the liquid - flush and bleed the entire hydraulic drive, replace the rubber parts;

- - jamming of the master cylinder pistons - check and, if necessary, replace the cylinder

Braking one wheel with the pedal released:

- - kink or weakening of the coupling springs of the parking brake pads - replace the springs;

- - jamming of the piston in the working cylinder due to contamination or corrosion of the housing - replace the working cylinder and bleed the system;

- - swelling of the sealing rings of the working cylinder due to the ingress of impurities into the liquid - replace the working cylinder and bleed the hydraulic brakes;

- - violation of the position of the caliper relative to the brake disc when the mounting bolts are loosened - tighten the mounting bolts, if necessary, replace the damaged parts;

- - incorrect adjustment of the parking brake system - adjust the parking brake system;

- - ABS malfunction - you need to check the ABS

Sliding or pulling the car to the side when braking:

- - jamming of the piston of the working cylinder - replace the working cylinder;

- - clogging of a tube due to a dent or blockage - replace or clean the tube;

- - contamination or oiling of discs, drums and pads - clean the brake parts;

- - the wheel alignment angles are violated - adjust the wheel alignment angles;

- - different tire pressure of the wheels - set normal tire pressure;

- - one of the circuits of the brake system does not work - replace damaged parts, pump the system. If it does not lead to the desired result, check the ABS;

Increased brake pedal force when braking:

- - the vacuum amplifier is faulty - replace the amplifier;

- - the hose connecting the vacuum booster and the engine intake pipe is damaged, or its fastening is loose - replace the hose;

- - swelling of the rubber seals of the cylinders due to the ingress of gasoline, mineral into the working fluid oils - replace cylinders, flush and bleed the system

Squeak or vibration of the brakes:

- - oiling friction linings - clean the linings with a wire brush using warm water and detergent. Eliminate causes of liquid or grease ingress

- - wear of the pads or foreign inclusions in them - replace the pads