In the article, we will consider why engine interruptions occur and how to determine by the appearance of the candles how a particular cylinder works

When an interruption occurs, the engine idles erratically, consumes gasoline quickly and does not develop sufficient power

It is also possible for the exhaust gas converter to fail

Interruptions occur due to a malfunction of the injectors or a gasoline pump, a malfunction of the cylinder candles, air leakage into one of the cylinders

To determine how the engine is running, start the engine and let it idle

We approach the exhaust pipe and listen to the sound of the exhaust

You can put your hand near the cut of the exhaust pipe - this way interruptions feel better

The sound should be even, one tone

Popping from the exhaust pipe at regular intervals indicates that one cylinder is not working due to a faulty spark plug, no spark, injector failure, heavy air leakage into one cylinder, or low compression in the cylinder

Popping at irregular intervals can be caused by dirty injector nozzles or dirty spark plugs

In this case, all spark plugs can be replaced

If the pops are irregular, stop the engine and open the hood.

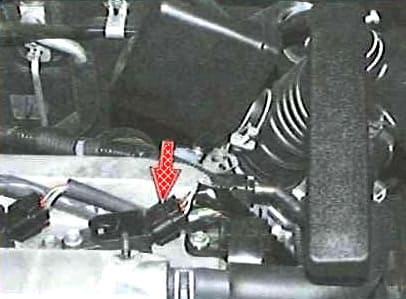

Checking the fastening of the wire blocks on the ignition coils

Unscrew all the spark plugs

If the candle is black and damp, it should be replaced

If all the candles look good, put them back in place and connect the high-voltage wires.

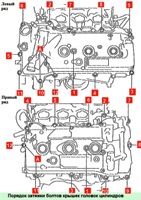

The order of operation of cylinders 1-3-4-2, the numbering of cylinders 1, 2, 3, 4, is carried out from the engine crankshaft pulley

We take a spare candle and fix it on the engine in any way (reliable contact of the candle body with the ground is required, otherwise the control unit or ignition coil will fail)

Connect the ignition coil of the first cylinder to the spare spark plug

Starting the engine

If engine interruptions do not increase, replace the spark plug in the first cylinder.

We put on the ignition coil and start the engine.

If the interruptions have intensified, we consistently repeat this procedure with all cylinders in order to detect a faulty candle

If, as a result of the measures taken, engine interruptions are not eliminated, you need to check the compression in the cylinders

Normal compression is more than 1.39 MPa (13.9 kgf/cm 2), the difference is more than 0.1 MPa (1 kgf/cm 2) in one cylinder indicates the need for engine repair

Determining the state of the engine by the type of candles

If a 2AZ-FE engine is installed, DENSO SK20R11 or NGK IFR6A11 iridium spark plugs

The 2GR-FE engine is equipped with spark plugs with iridium electrodes with a protruding spark gap brand DENSO FK20HR11

Greyish-yellow or brown color and slight wear on the electrodes.

Exact matching of spark plug heat value for engine and operating conditions

Dry soot deposits indicate a rich air-fuel mixture or late ignition

In this case, it causes misfiring, difficult starting and erratic engine operation.

It is necessary to check if the air filter is clogged, the serviceability of the coolant temperature and intake air temperature sensors

The reason is oil entering the combustion chamber through the valve guides or piston rings

In this case, difficult starting, misfiring of the cylinder and twitching of the running engine.

It is necessary to repair the cylinder head and the piston group of the engine.

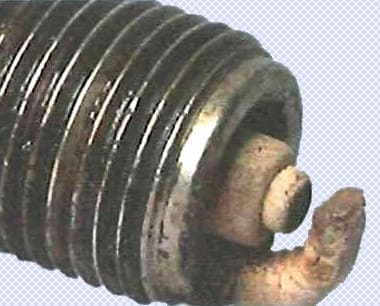

Deposits on the insulator skirt of brick-red iron oxides from anti-knock iron-containing additives (ferrocenes) to gasoline.

They are deposited in an even, dense layer.

When the engine is running under heavy load, under the influence of high temperature and pressure in the combustion chamber, the oxides are reduced into conductive paths of pure iron, which close the central electrode with the mass

This causes misfiring and, as a result, a drop in engine power and increased fuel consumption.

In addition, the catalytic converter of exhaust gases can be damaged, which overheats greatly when unburned gasoline in the engine cylinders enters it.

The plaque is practically not removed mechanically and does not fade during prolonged movement at high speed.

If this plaque appears on new candles after a short run, you need to change the place of refueling

If it is not possible to immediately replace the candles with new ones, try to remove this coating by immersing the candles in a rust converter for ten minutes.

After that, clean the plaque with a non-metal brush and rinse the candles first with water and then with gasoline

Early ignition.

The insulator is white, but may be dirty due to spark gaps and deposits from the combustion chamber.

May cause engine damage.

It is necessary to check the type of spark plug, the cleanliness of the injector nozzles and the fuel filter, the operation of the cooling and lubrication system

Light brown deposits encrusting the center and side electrodes.

Isolated from oil or gasoline additives.

A large number of them can lead to the insulation of the spark plug electrodes, causing gaps in sparking and interruptions during acceleration.

If excessive deposits form after a short time or low mileage, the valve guide valve stem seals must be replaced to prevent oil from entering the combustion chamber

If deposits form during a long run, the reason is the quality of gasoline

This is a sign of detonation and could damage the piston.

Make sure that the octane rating of gasoline is correct

Damage can be caused by foreign objects entering the combustion chamber, and if a spark plug that is too long is used, its electrodes may catch on the piston.

This will destroy the spark plug, disable the cylinder, and possibly damage the piston.

It is necessary to remove the foreign object from the cylinder and / or replace the spark plug