Usually, oil seals are changed due to oil leakage from under the seals or when repairing the engine

Replacing the front crankshaft oil seal

Remove the timing belt (see "Checking the condition and replacing the timing belt").

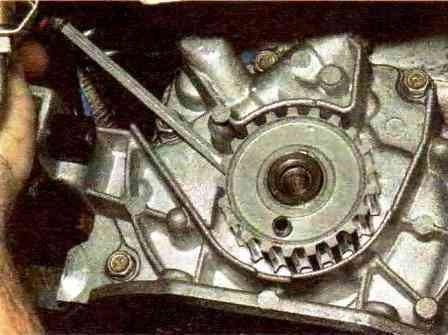

Pry off the crankshaft gear pulley with a screwdriver

Remove the pulley from the toe of the crankshaft

Remove the key from the groove of the crankshaft

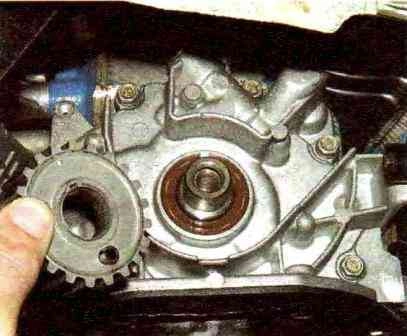

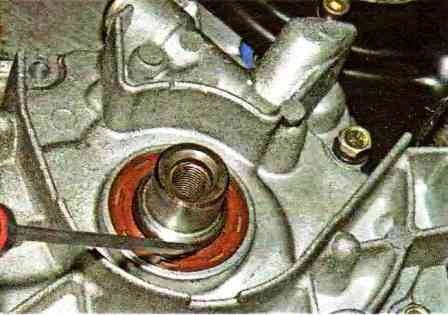

Pry off the oil seal with a screwdriver

Remove the oil seal from the oil pump body

We apply a layer of engine oil to the working edge of the new oil seal and press the oil seal with a 30 tool head or a piece of a suitable pipe

Further assembly is carried out in the reverse order.

Replacing the crankshaft rear oil seal

We perform work on a flyover or a viewing ditch.

We remove the gearbox (see "Removing and installing the gearbox"), the casing and the clutch disc.

Marker mark the position of the flywheel relative to the crankshaft.

We screw the M10X1.25 stud into the hole of the cylinder block (or the bolt of the clutch housing to the cylinder block) and stop the flywheel from turning with a screwdriver, placing it between the teeth of the flywheel and resting it on the stud.

With a 17 head, we unscrew the six flywheel mounting bolts

Remove the washer

Remove the flywheel

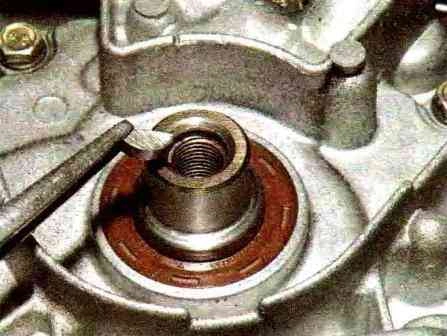

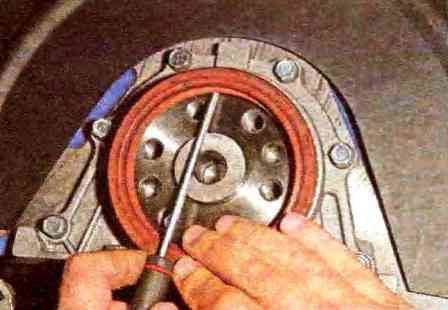

With a thin slotted screwdriver, carefully drive the working edge of the oil seal onto the crankshaft flange.

Pry off the oil seal with a screwdriver and remove it from the holder.

We apply a thin layer of engine oil to the working edge of the new oil seal

Using the old oil seal as a mandrel, we press in the new oil seal

We install the flywheel according to the marks made earlier.

Before tightening the flywheel mounting bolts apply sealant to their threaded part.

We wrap and evenly tighten the bolts with a torque of 75–85 Nm.

Further assembly is carried out in the reverse order.