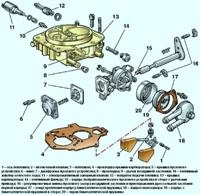

The intermediate shaft drives the oil pump

In addition, camshafts are driven through it

The intermediate shaft rotates in two sleeve bearings.

Remove:

Remove the upper and lower camshaft drive chains (How to replace the timing chains and gears ZMZ-405, ZMZ-406).

The lower chain does not need to be removed from the crankshaft gear.

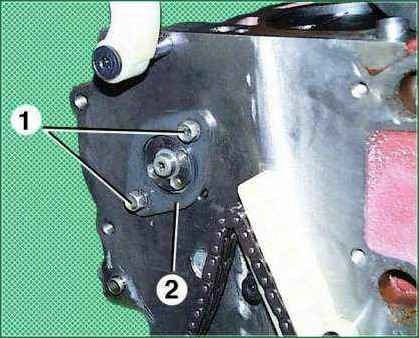

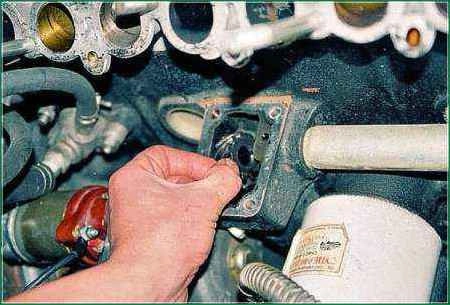

Remove screws 1 and remove intermediate shaft flange 2.

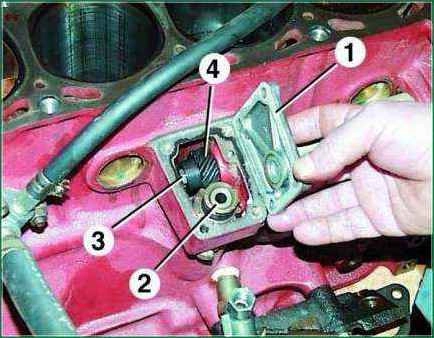

Remove the four bolts securing the cover 1 and remove the cover with the gasket.

Pull up oil pump drive 2 with driven gear.

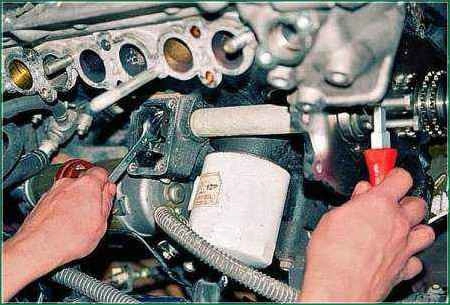

In order to unscrew the nut 3 and remove the drive gear 4 of the oil pump drive, it is necessary to block the intermediate shaft from turning.

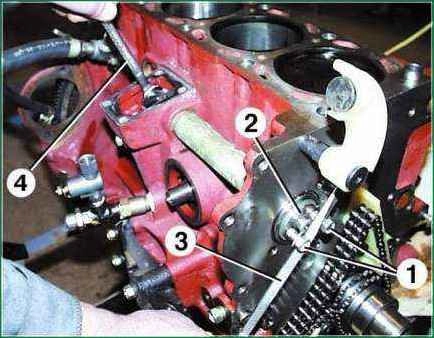

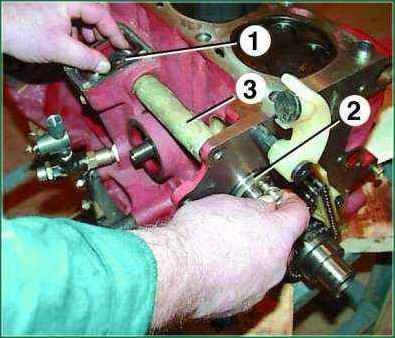

To do this, screw two bolts 1 into the threaded holes of the intermediate shaft 2.

Holding the shaft by the bolts 1 with a screwdriver 3, unscrew the pinion nut with a wrench 4.

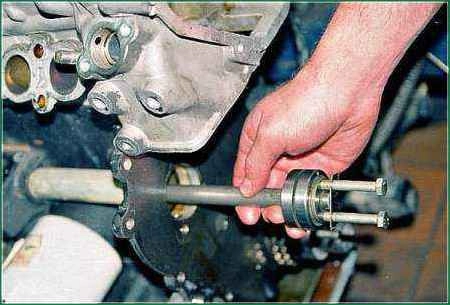

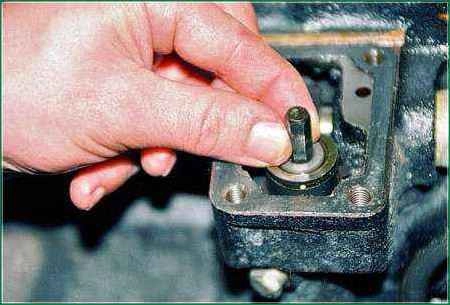

Holding the drive gear 1 with your hand, remove the intermediate shaft 2.

If it is necessary to replace the bushings of the intermediate shaft, you must first press out the pipe 3 of the intermediate shaft using a special tool.

Then press out the intermediate shaft bushing using a special tool.

Without removing the cylinder head:

If you do not remove the cylinder head, then remove the intake manifold (described in the article - Removing and installing the cylinder head ZMZ-406).

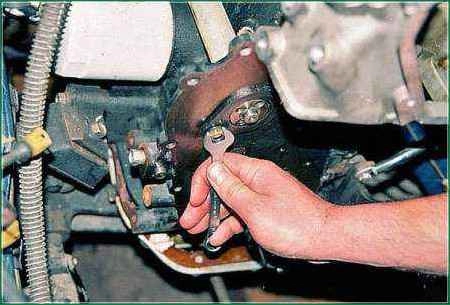

Using the “12” key, unscrew the two bolts securing the intermediate shaft flange and remove the flange.

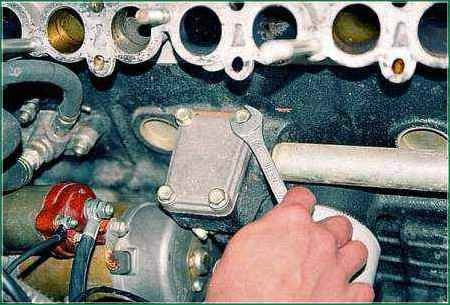

Using the “12” key, unscrew the four bolts securing the drive cover and remove it, being careful not to damage the gasket.

Remove the drive.

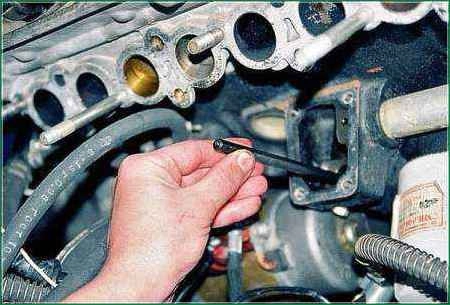

We wrap two bolts (M8) into the threaded holes of the end of the intermediate shaft.

Using the “12” key, unscrew the nut securing the intermediate shaft gear, rotating the shaft with a screwdriver inserted between the bolts.

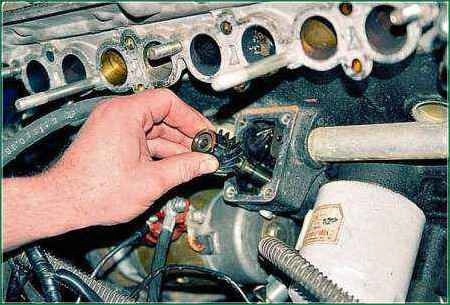

We take out the intermediate shaft gear and the hexagonal drive shaft from the block.

Inspection, Troubleshooting and Repair

After removing, rinse all parts in gasoline.

Inspect the gap weft shaft. If it has cracks, replace the shaft.

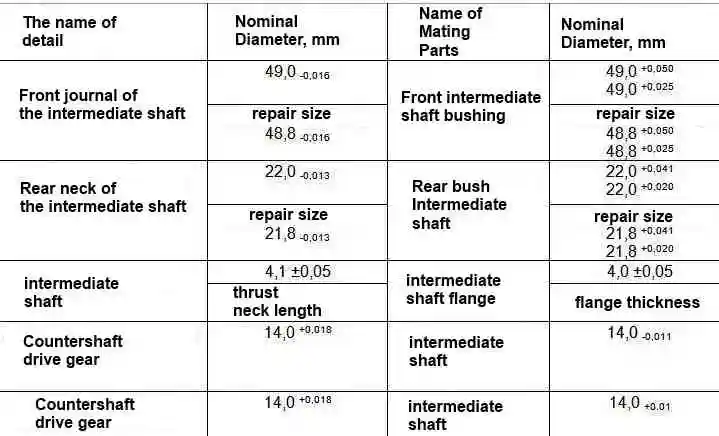

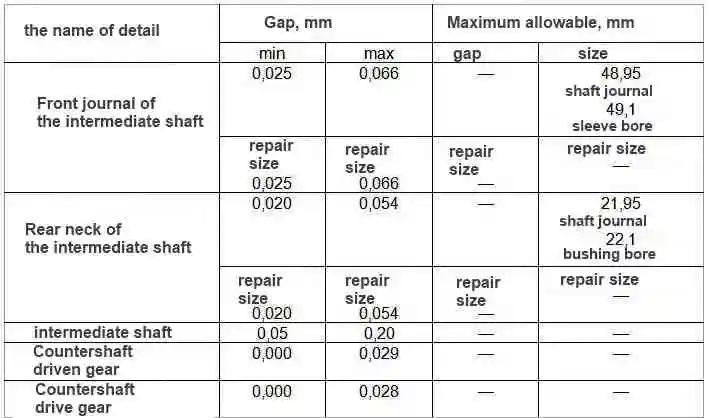

If there are marks, scratches, scuffs, etc. on the shaft journals, grind the shaft journals to the repair size.

If grinding to the repair size fails to completely remove scratches, scuffs, etc., replace the shaft.

Measure the intermediate shaft journals.

If the diameter of the front neck is less than 48.95 mm, and the rear neck is less than 21.95 mm, they must be ground to the repair size.

The intermediate shaft bushings cannot be repaired.

If they have scuffs, nicks, scratches, etc., they must be replaced.

Increased thickness bushings are available for spare parts.

After pressing new bushings into the cylinder block, they must be bored to the nominal or repair size.

Bore the bushings in one pass to maintain the alignment of the holes.

When pressing the bushings, set them so that the holes in the bushings coincide with the oil channels in the cylinder block.

We assemble the drive in reverse order.

In this case, we recommend installing the hexagonal drive shaft last

Install the shaft in the reverse order of removal.

Before installing, lubricate the shaft journals and gears with engine oil.

The dimensions of the journals and bushings of the intermediate shaft are shown in the table.

Nominal and maximum permissible dimensions and fit of mating parts of the intermediate shaft of the engine mod. 406:

Install the shaft in the reverse order of removal. Lubricate the shaft journals and gears with engine oil before installation.