An external sign of wear on the valve stem seals is the short-term appearance of blue smoke from the exhaust pipe after starting the engine, as well as when braking the engine after a long drive under load

There is usually no constant smoke.

Indirect signs - increased oil consumption in the absence of external leaks and oily spark plug electrodes.

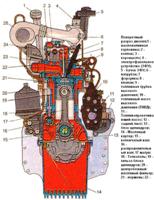

To replace the valve stem seals, the cylinder head must be removed from the engine.

You will need: the same tools as when replacing the head gasket, as well as pliers, a valve spring compressor, round-nose pliers or tweezers to remove valve cotters, a mandrel for pressing oil seals, a hammer.

Remove the cylinder head (see Removing and installing the ZMZ-406 cylinder head)

Remove the hydraulic pusher.

It is more convenient to remove the hydraulic pusher using a strong magnet or suction cup.

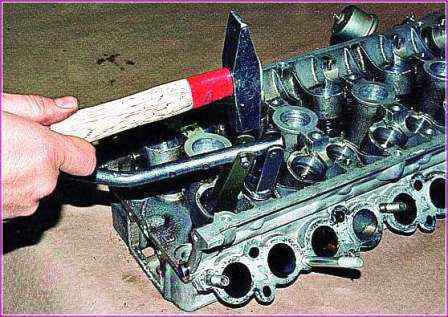

Compress the valve springs with a tool, placing a suitable stop under the valve plate on the back of the head, and remove the crackers from the spring plate.

In order for the plate of springs to come off easily from the crackers, we apply a light blow with a hammer.

Remove the tool and remove the spring plate

Remove the springs.

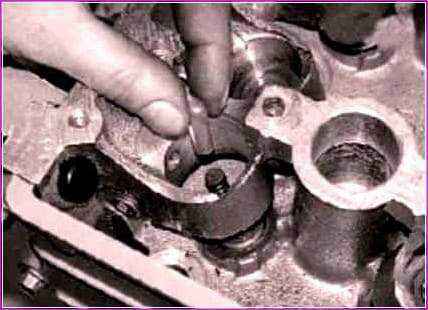

Use a puller to remove the oil seal.

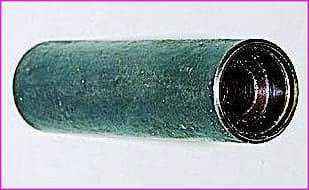

This is what an inertial oil seal remover looks like.

The puller shown has a mandrel on the other end to press on the caps.

Do not remove the cap by working with pliers or prying it from both sides with screwdrivers.

The guide sleeve, on which the cap is put on, is made of sintered metal, and its edge breaks off easily.

Put on the valve stem the mandrel from the set of valve stem seals, which protects the working edge of the cap from damage by the edges of the grooves on the valve stem for crackers.

If there is no mandrel, you can wind the tape.

Lubricate the inside of the new valve stem seal with engine oil and slide the cap over the valve stem to the guide sleeve.

Install the mandrel for pressing the cap. With light blows of the striker on the mandrel, press the cap all the way

Remove the safety mandrel, install the springs and valve cotters in the reverse order of removal.

After installing the cotters and removing the valve spring compressor, apply a few light blows with a hammer on the end of the valve stem to ensure the cotters fixed in the groove of the rod.

If the skewed crackers remain unfixed, when the engine is started, the “dry” valve will fall into the cylinder, which will lead to a serious engine failure.

Install the hydraulic pusher.

Before installing the hydraulic tappet, dip it into a container of engine oil and press the tappet sleeve several times until air bubbles stop escaping.

The hydraulic pusher should become rigid.

Replace the valve stem seals in the same way.

Reinstall the cylinder head and all removed components and parts on the engine.