Checking the voltage regulator relay

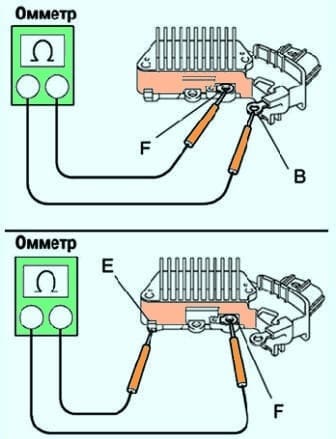

Using an ohmmeter, check the continuity between diodes F and B (fig. 1)

When the positive and negative poles between terminals F and B are connected in a single circuit, conduction should be in only one direction.

If there is continuity in both directions, one of the diodes may be broken.

In this case, replace the voltage regulator.

Using an ohmmeter, check the continuity between diodes F and E.

Checking the Rotor

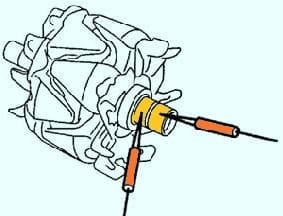

Check for an open circuit in the field winding.

Using an ohmmeter, measure the resistance between the slip rings (fig. 2).

Rated resistance (cold): 2.7-3.1 ohms.

If the resistance tends to infinity, i.e. circuit is open, replace the rotor.

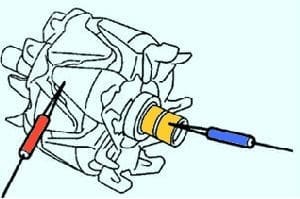

Check if the field winding is shorted to ground (Fig. 3).

Using an ohmmeter, measure the resistance between the rotor pole and the slip ring.

If the resistance is 0 (circuit is closed), then replace the rotor.

Checking slip rings

Check the running surfaces of the slip rings. They should not have burrs or chips.

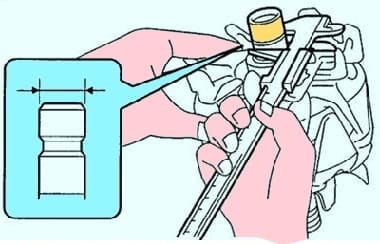

Measure the diameter of the slip rings with a caliper (Fig. 4).

Standard diameter: 14.2-14.4mm. Minimum allowable: 12.8 mm.

If the slip ring diameter is less than the minimum, the rotor must be replaced.

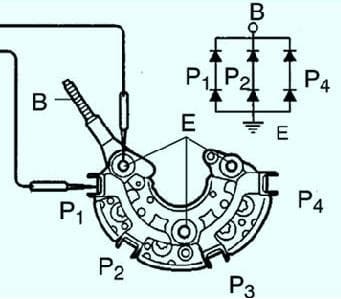

Checking the rectifier unit

Check the positive valve.

Connect the negative probe of the ohmmeter to the positive terminal of the rectifier unit, and connect the positive probe in series to each of the other three terminals.

Check for continuity (closed circuit) in all three dimensions (Figure 5).

Reverse the polarity of the tester probes and repeat the first procedure.

Make sure the circuit is open in all three dimensions (resistance tends to infinity).

Check the negative valve.

Connect the positive probe of the ohmmeter to the negative terminal of the rectifier unit, and connect the negative probe in series to each of the other three terminals.

Check for continuity (closed circuit) in all three dimensions.

Reverse the polarity of the tester probes and repeat the first procedure.

Make sure the circuit is open in all three dimensions (resistance tends to infinity). If the test conditions are not met, replace the rectifier unit.

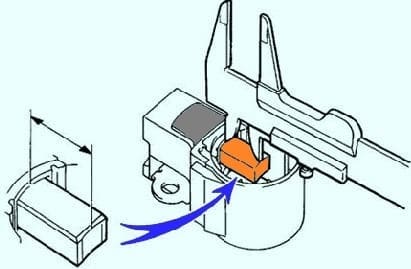

Checking the generator brushes

Measure the length of the protruding part of the brushes (fig. 6).

Standard length: 9.5 - 11.5 mm.

Minimum allowable: 1.5 mm.

If the length of the brushes is less than the minimum allowable, replace ite brushes and brush holder assembly.

Checking the alternator bearings

Check the front bearing.

Check that the front bearing runs smoothly without binding.

Replace the bearing if necessary.

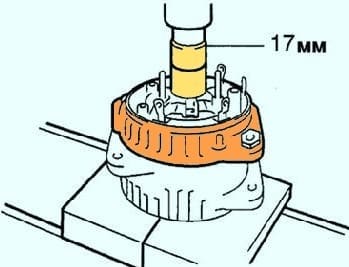

Remove the four screws and remove the bearing holder.

Using a press and socket (17 mm), press in the front bearing (fig. 7).

Using a special punch, press the new front bearing into the drive side alternator cover.

Install the bearing holder and tighten the four screws securing it. Tightening torque: 3 Nm.