The engines installed on Toyota Camry vehicles are equipped with an electronic engine management system with multiport fuel injection.

This system ensures that the latest emissions and fumes regulations are met while maintaining high driving performance and low fuel consumption.

The control device in the system is the electronic control unit (ECU).

Based on the information received from the sensors, the ECU calculates the parameters for fuel injection control and ignition timing control.

The ECU also controls the operation of the electric motors of the engine cooling fan and the electromagnetic clutch for turning on the air conditioning compressor.

The electronic unit performs the function of self-diagnosis of the system elements and notifies the driver of any malfunctions

If individual sensors and actuators fail, the ECU turns on emergency modes that ensure engine performance.

The amount of fuel supplied by the injectors is determined by the duration of the electrical signal from the ECU.

The electronic unit monitors data on the state of the engine, calculates the need for fuel and determines the required duration of fuel supply by the injectors (signal duration).

To increase the amount of fuel supplied, the duration of the signal increases, and to decrease the amount of fuel, it decreases

The engine management system, along with the electronic control unit, includes sensors, actuators, connectors and fuses.

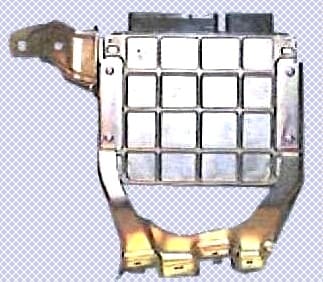

Electronic engine control unit

The electronic control unit (controller) is connected by electrical wires to all sensors of the system.

Receiving information from them, the block performs calculations in accordance with the parameters and control algorithm stored in the memory of the programmable read-only memory (PROM), and controls the system's executive devices.

The program version recorded in the PROM memory is indicated by the number assigned to this ECU modification

The control unit detects a fault, identifies and remembers its code, even if the fault is unstable and disappears (for example, due to poor contact).

The engine management system malfunction indicator lamp in the instrument cluster goes out after three ignition on-off cycles after the failed unit is restored.

After repair, the fault code stored in the memory of the control unit must be erased.

To do this, turn off the power to the unit for 1 minute (remove the fuse for the power supply circuit of the electronic control unit or disconnect the wire from the “-” terminal of the battery).

A DC voltage of 5 and 12 V is supplied through the controller to various sensors and switches of the control system.

Because the electrical resistance of the power circuits is high, the test lamp connected to the system outputs does not light up.

To determine the supply voltage at the computer terminals, use a voltmeter with an internal resistance of at least 10 MΩ.

The computer is not repaired, in case of failure it must be replaced.

Crankshaft position sensor

The inductive type crankshaft position sensor is designed to synchronize the operation of the electronic control unit with the TDC of the pistons of the 1st and 4th cylinders and the angular position of the crankshaft

The sensor is installed in front of the engine opposite the setting disk on the engine crankshaft.

The driving disk is a toothed wheel with cavities.

Two teeth are sheared to create a synchronization pulse ("reference" pulse), which is necessary to coordinate the operation of the control unit with the TDC of pistons in the 1st and 4th cylinders.

As the crankshaft rotates, the teeth change the magnetic field of the sensor, inducing AC voltage pulses.

The control unit determines the crankshaft speed using the sensor signals and sends pulses to the injectors.

If the sensor fails, the engine cannot be started.

Camshaft position sensor

An inductive type camshaft position sensor is installed at the rear of the cylinder head

When the intake camshaft rotates, the protrusion of its master disk changes the magnetic field of the sensor, inducing voltage pulses with alternating current.

Sensor signals are used by the controller to organize phased fuel injection in accordance with the order of operation of the cylinders, as well as to control the change in valve timing depending on the engine operating mode.

If a malfunction occurs in the camshaft position sensor circuit, the controller stores its code in its memory and turns on the signal lamp.

Coolant temperature sensor

The coolant temperature sensor is installed in the engine cooling system

The sensing element of the sensor is a thermistor, the electrical resistance of which changes inversely with temperature.

At a low coolant temperature (-20ºС), the thermistor resistance is 15-30 kOhm, when the temperature rises to +80ºС, it decreases to 320 Ohm.

The electronic unit supplies the temperature sensor circuit with a constant reference voltage.

The voltage of the sensor signal is maximum on a cold engine and decreases as it warms up.

The electronic unit determines the engine temperature from the voltage value and takes it into account when calculating the injection and ignition control parameters.

If the sensor fails or there is a violation in its connection circuit, the ECU sets the fault code and remembers it.

In addition, the sensor indirectly serves as a peak of the coolant temperature indicator in the instrument cluster.

Based on information from this sensor, the electronic engine control unit changes the readings of the pointer.

To fix the problem, check the reliability of the contact connections in the wiring to the sensor or replace the sensor.

Combined mass air flow and air temperature sensor

The combined mass flow and intake air temperature sensor is adopted in the air sleeve between the air filter and the throttle assembly

The principle of operation of the mass air flow sensor is based on maintaining a constant temperature of the resistors (the higher the air flow rate, the more current is required to maintain the temperature of the resistor).

The principle of operation of the intake air temperature sensor is similar to that of the coolant temperature sensor.

Depending on the readings of these sensors, the ECU adjusts the amount of fuel injected into the cylinder to obtain the optimal working mixture.

Throttle position sensor

The throttle position sensor is integral with the throttle cover

The principle of operation of the sensor is based on the Hall effect.

When the throttle valve is turned (from the action on the control pedal), the voltage at the output of the sensor changes.

It is below 2.5 volts when throttle is closed.

When the damper opens, the voltage at the output of the sensor rises, when the damper is fully open, it should be more than 4 V.

By monitoring the output voltage of the sensor, the controller adjusts the fuel supply depending on the throttle opening angle (i.e. at the request of the driver).

The throttle position sensor does not require adjustment, since the control unit perceives idling (that is, full throttle closing) as a zero mark

Oxygen concentration sensors

Oxygen concentration sensors (lambda probes) are screwed into the threaded holes of the collector and the exhaust pipe of the exhaust system

The sensor at the inlet to the collector is used to control the composition of the air-fuel mixture, and the sensor at the outlet is used to evaluate the efficiency of the converter.

In the metal flasks of the sensors there is a galvanic cell washed by the exhaust gas flow.

Depending on the oxygen content in the exhaust gases, as a result of the combustion of the air-fuel mixture, the voltage of the sensor signals changes.

Information from each sensor is sent to the control unit in the form of low and high level signals.

At a high level signal (about 4.2 V) from the sensor at the collector inlet, the control unit receives information about the high oxygen content.

A low level signal (about 2.2 V) from this sensor indicates a low oxygen content in the exhaust gases.

The sensor at the outlet of the collector has different output characteristics: a high oxygen content corresponds to a low level signal (about 0.1 V), and a low oxygen content corresponds to a high level signal (about 0.9 V).

Constantly monitoring the voltage of the sensor signal, the control unit adjusts the amount of fuel injected by the injectors.

At a high signal level of the sensor at the inlet to the collector (lean air-fuel mixture), the amount of fuel supplied increases, and at a low signal level (rich mixture), it decreases.

If the level of the sensor signal at the output of the converter does not correspond to the values allowed for this mode of operation, the control unit identifies a malfunction of the collector.

The knock sensor is attached to the top of the cylinder block on the right side and detects abnormal vibrations (knock) in the engine.

The sensing element of the knock sensor is a piezoelectric plate.

During detonation, voltage pulses are generated at the output of the sensor, which increase with increasing intensity of detonation impacts.

The controller, based on the sensor signal, regulates the ignition timing to eliminate detonation fuel flashes.

During operation, the electronic engine control unit also uses the vehicle speed data received from the ABS control unit.

Warnings

Before removing any components of the fuel injection control system, disconnect the wire from the "-" terminal of the battery.

Do not start the engine if the cable lugs on the battery are loose.

Never disconnect the battery from the vehicle's electrical system while the engine is running.

When charging the battery, disconnect it from the car's on-board network.

Do not expose the ECU to temperatures above 65º C in working condition and above 80º C in non-working condition (for example, in a drying chamber).

It is necessary to remove the ECU from the car if this temperature is exceeded.

Do not disconnect or connect wires to the computer while the ignition is on.

Before carrying out electric welding work on the car, disconnect the wires from the battery and the wiring harness pads from the computer.

Perform all voltage measurements with a digital voltmeter with an internal resistance of at least 10 MΩ.

Electronic components used in the fuel injection system are designed for very low voltage, so they can be easily damaged by electrostatic discharge.

To prevent damage to the computer, do not touch its terminals with your hands.