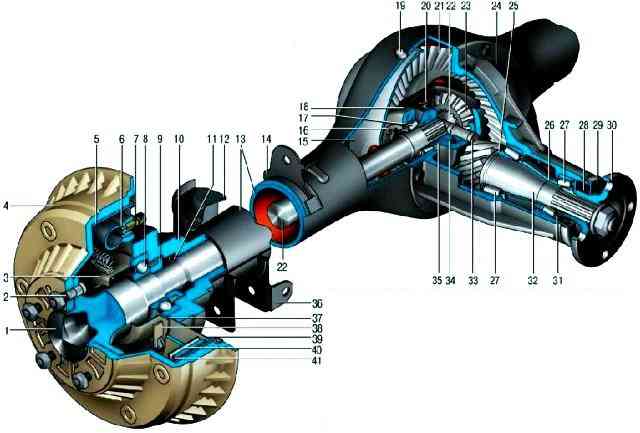

To the beam 13 (Fig. 1) of the rear axle is attached the gearbox housing 24, in which the main gear and differential are located

The drive 32 and driven 21 gears of the final drive are paired according to the contact patch and noise, so if one of them is damaged, both are replaced.

Between the inner rings of the bearings 27 of the drive gear there is a spacer sleeve 26, which, deforming when the drive gear nut is tightened, provides a preload in its bearings.

Adjusting ring 25 is installed between the end face of the drive gear and the inner bearing, which determines the correct position of the drive gear relative to the driven gear.

The driven gear of the final drive is attached to the flange of the differential box 35, which rotates on two bearings 17.

Fig. 1. Rear axle: 1 - decorative cap; 1 - stud fastening the brake drum and wheel; 3 - half shaft bearing oil deflector; 4 - brake drum; 5 - cast-iron drum ring; 6 - working cylinder of the rear brake; 7 - fitting for bleeding the brakes; 8 - half shaft bearing; 9 - locking ring of the bearing; 10 - rear axle beam flange; 11 - stuffing box; 12 - suspension spring cup; 13 - rear axle beam; 14 - mounting bracket for the upper longitudinal rod of the rear suspension; 15 - axle guide; 16 - differential bearing adjusting nut; 17 - differential box bearing; 19 - breather; 20 - satellite; 21 - driven gear of the main gear; 22 - axle shaft; 23 - axle gear; 24 - crankcase of the rear toast gearbox; 25 - adjusting ring; 26 - bearing spacer; 27 - drive gear bearings; 28 - drive gear oil seal; 29 - mud deflector; 30 - flange; 31 - oil deflector; 32 - main gear drive gear; 33 - axis of the satellites; 34 - support washer of the axle gear; 35 - differential box; 36 - bracket for fastening suspension parts; 37 - plate for mounting the axle shaft bearing; 38 - holder of bolts for fastening the plate; 39 - rear axle shield; 40 - rear brake pad; 41 - brake pad

The preload in these bearings, as well as the gap between the teeth of the drive and driven gears, is adjusted with nuts wrapped in split bearing beds.

Semi-axial gears 23 are installed in the cylindrical sockets of the differential box and rest on the box through support washers 34.

By selecting washers for thickness, a side clearance of 0–0.1 mm is set between the teeth of satellites and side gears.

The half shaft 22 with its inner end enters the spline hole of the side gear, and the outer end rests on the ball bearing 8, which is fixed on the half shaft with a locking ring 9.

The axle shaft bearing is sealed in the seat of the beam on the inside with a self-clamping gland 11, and on the outside with a rubber ring sandwiched between the brake shield 39 and the flange of the rear axle beam.

The bearing is fixed in the seat of the beam by plate 37, which, together with the oil deflector 3 and the shield, is bolted to the beam flange.

Checking the tightness of the rear axle seals

Check the tightness of the seals by visual inspection.

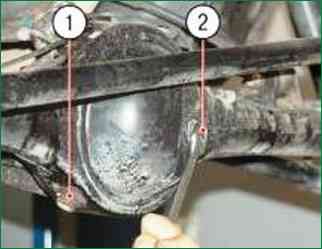

It is more convenient to check from the bottom of the car mounted on a lift or inspection ditch. Below are the places where oil leakage is possible.

Drain 1 and filler 2 plugs.

If oil leaks from under the hole plugs, tighten them.

Reducer flange connector.

Drive gear seal

If the half shaft oil seal fails, then it flows here.

Oil leaking from seals can cause a clogged breather

If traces of oil leakage are found, clean the breather from dirt, check the freedom of movement of the breather cover in all directions, carefully wipe the leaks and after a run of 20–30 km again they arelook.

If traces of leakage are found again, it is possible that the breather is clogged and in the rear axle housing, when it is heated during operation, pressure increases, squeezing oil out of the seals.

Remove the breather and clean it.

If, after cleaning, oil leakage from the seals is observed, replace the breather, as it may be defective (valve sticking).

If oil is still leaking from the seals even with a good breather, replace the seals.