Main main gear malfunctions:

- - The bearings of the rear axle gearbox are worn, their preload is broken, the landing is weakened (uniform noise from the rear axle)

- - The teeth of the gears of the main gear are worn out, the lateral clearance in the engagement is broken, the scuffing on the teeth is a howl from the side of the rear axle, which decreases or disappears when the load is reduced (the “gas” pedal is released)

Rear axle dismantling

It is more convenient to work on the inspection ditch together.

Drain the oil (see Changing the oil in the rear axle gearbox of a Gazelle car).

We disconnect the driveline from the rear axle (see Inspection and removal of the driveshaft of a Gazelle car).

We clean the main gear housing from dirt.

We take out the axle shafts on both sides of the car (see Removing the rear wheels and axle shafts of the Gazelle car).

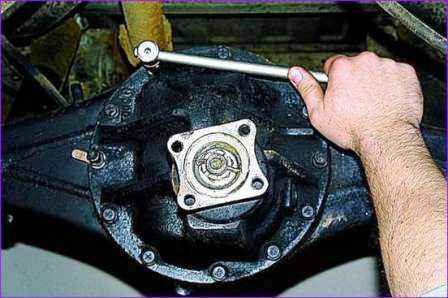

With a key or a “14” head, we unscrew ten bolts securing the gearbox to the rear axle beam.

We remove the gearbox from the beam, while trying not to damage the gasket.

For the convenience of work, we install the gearbox on the stand.

Remove the drive gear flange with the cuff.

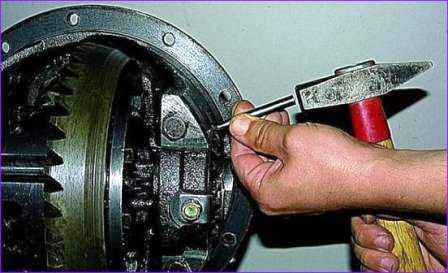

With a punch, we mark the relative position of the differential bearing caps and their nuts, as well as the caps themselves relative to the crankcase.

Remove the drive gear flange with the cuff.

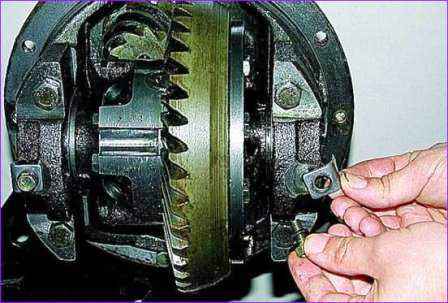

Use the “12” key to unscrew the bolts of the locking plates

Remove the locking plates

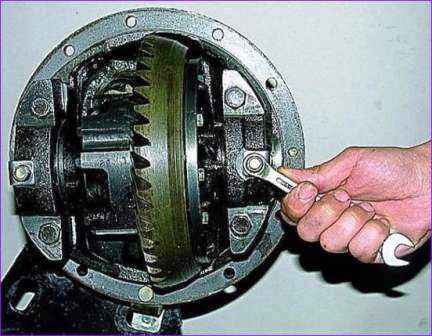

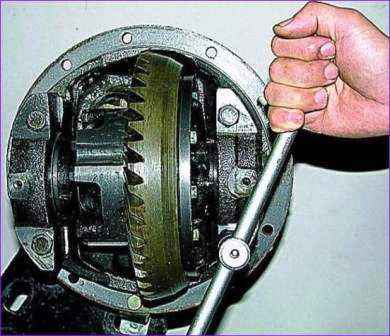

Using a key or a “17” head, unscrew the bearing cap bolts

Remove the cover.

Remove the second cover in the same way.

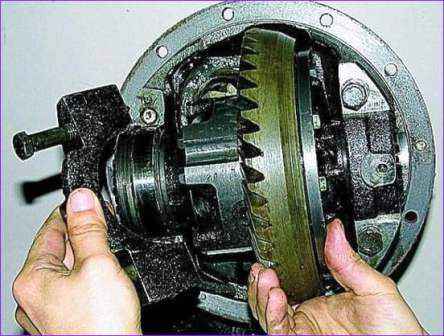

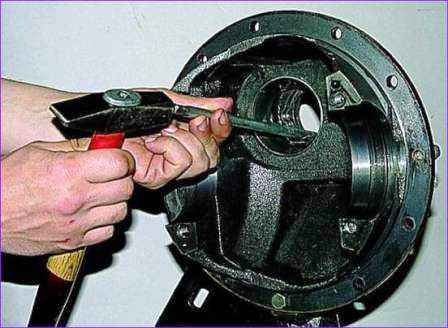

With a special wrench or a large screwdriver, unscrew the adjusting nuts of the bearings

remove adjusting nuts

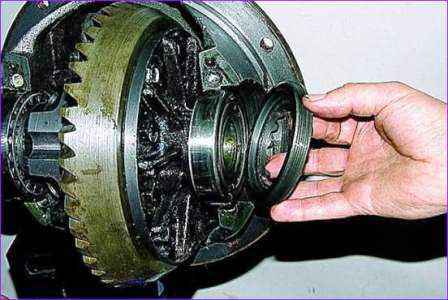

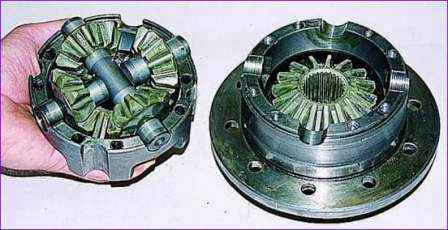

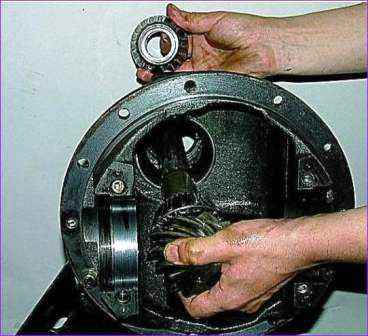

Remove the box of satellites with the driven gear.

EU If the bearings are not replaced, we mark their outer rings in order to install them in their original places during assembly.

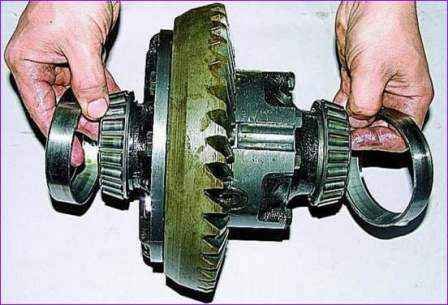

The driven gear is installed on the pinion box in only one position, therefore, to simplify assembly, we mark the relative position of the gear and the housing.

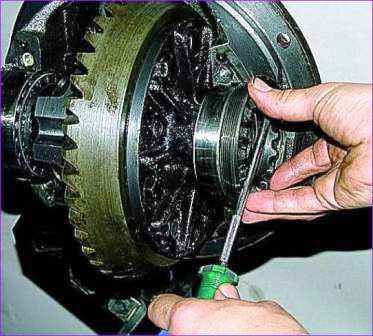

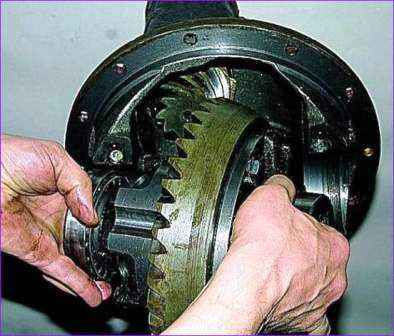

With a key or a “17” head, we unscrew 10 gear mounting bolts.

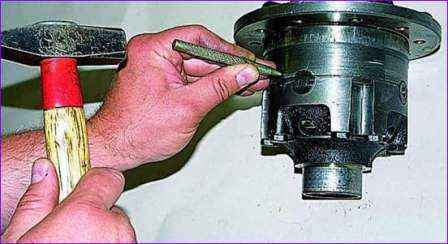

With light hammer blows through a soft metal drift, knock the gear off the satellite box and remove it.

Special recesses are provided for the puller legs on the satellite box.

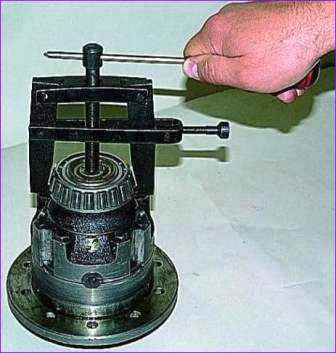

Installing a special puller

Remove the inner bearing rings with a puller.

Similarly, remove the second bearing.

In the absence of a puller, insert a chisel between the end of the inner ring of the bearing and the differential box.

By striking the chisel, we move the inner ring of the bearing.

Insert two powerful screwdrivers (or mounting blades) into the resulting gap

We press the inner ring of the bearing with the cage and rollers.

With a center punch we mark the relative position of the parts of the differential box and the axes of the satellites.

Using the “13” key, we unscrew the eight bolts connecting the parts of the differential box

Cautiously tapping with a hammer through a soft drift, we separate the box

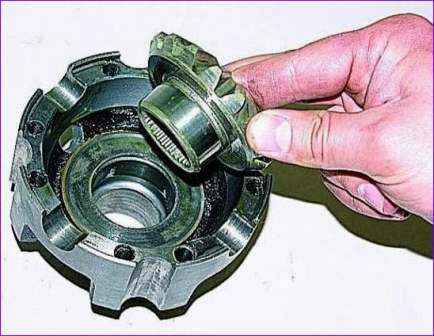

We take out the side gear from the removed half of the box

Remove the support washer.

We take out the axles together with the satellites and their washers.

Remove satellites and washers from axles

Remove the second side gear

Remove the support washer.

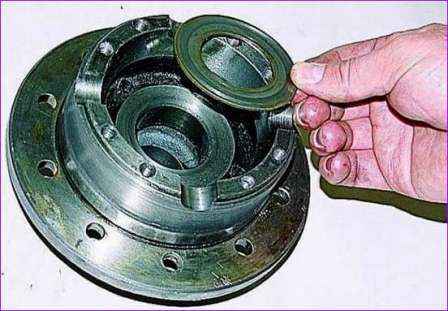

We remove the drive gear from the gearbox housing (it can be knocked out with hammer blows through a soft metal spacer on the end of the shaft) and the inner ring of the front bearing.

Remove the spacer ring.

Compress the inner ring of the rear bearing from the gear shank

Remove the drive gear adjusting ring

With a drift we knock out the outer ring of the front bearing

Take out the ring.

Similarly, we knock out the outer ring of the rear bearing

Before assembly, we wash all parts in kerosene or diesel fuel and inspect them

Any cracks are unacceptable on the parts.

Gear teeth should be free of scuffing, chipping and heavy wear.

The bearings should rotate easily without clicking or binding.

On rollers and rings, chipping, chips and heavy wear are unacceptable.

Bearing cages must not be torn or deformed.

We replace damaged and worn parts.

In any case, after a run of more than 100 thousand km, we recommend replacing the bearings, regardless of their condition.