Removal and inspection of the driveline was discussed in the article - “Inspection and removal of the cardan shaft of the Gazelle car”

Malfunctions of the cardan shaft are discussed in the article - “Design Features of the Cardan Drive of a Gazelle Car”

Gimbal disassembly

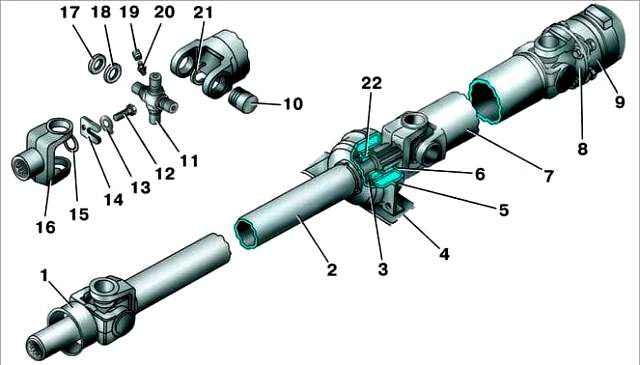

Gimbal transmission; 1 - sliding fork; 2 - intermediate cardan shaft; 3 - reflector; 4 - intermediate support bracket; 5 - intermediate support; 6 - reflector; 7 - cardan shaft of the rear axle; 8 - flange of the cardan shaft; 9 - flange of the drive gear of the main gear; 10 - needle bearing of the cross; 11 - cross; 12 - coupling bolt; 13 - lock washer; 14 - locking plate; 15 - sealing ring; 16 - slotted fork; 17 - sealing cuff; 18 - reflector; 19 - protective cap; 20 - grease fitting; 21 - retaining ring; 22 - intermediate support bearing

Since the driveline is balanced at the factory, each time it is disassembled and reassembled, it is necessary to maintain the original relative position of the shafts.

Otherwise, a noticeable vibration may occur when the vehicle is moving.

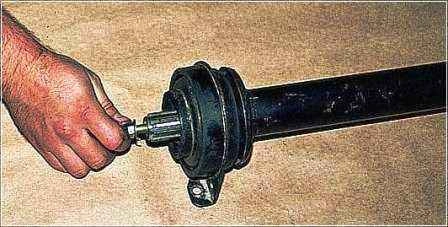

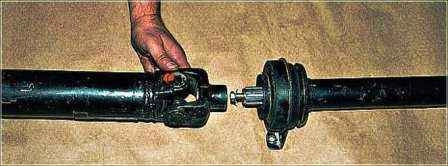

In order for the splines of the shank of the intermediate shaft and the splined fork to return to their previous position during assembly, we make marks with paint or a chisel on the pipe of the intermediate shaft

We make marks with paint or a chisel on the slotted fork of the middle hinge.

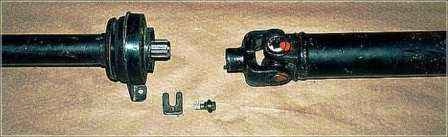

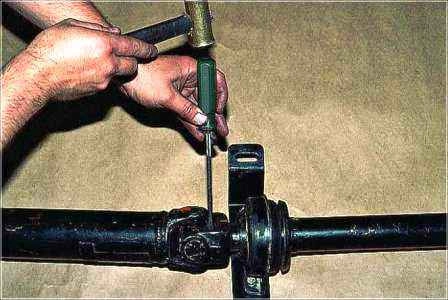

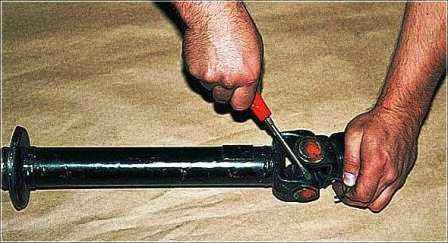

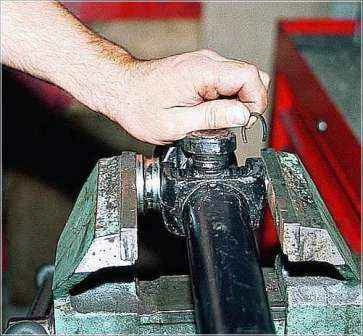

Use a screwdriver to bend the protrusion of the lock washer located inside the slotted fork

Having inserted a wrench or screwdriver into the fork, hold the hinge and unscrew the bolt three turns.

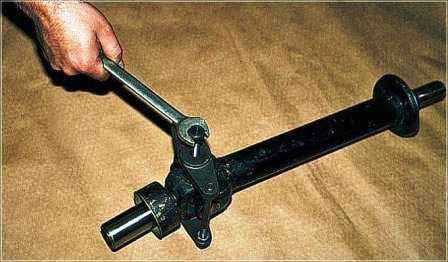

We take out the U-shaped plate with pliers

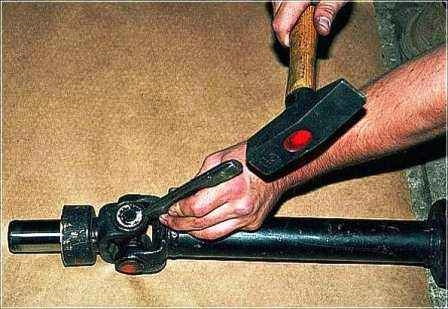

Using a copper hammer or through a spacer, we knock the fork off the splines of the intermediate shaft

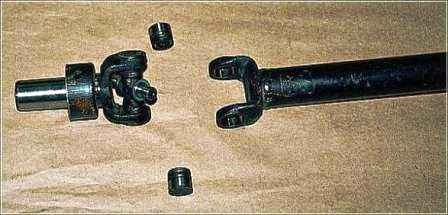

Unscrew the bolt with the lock washer.

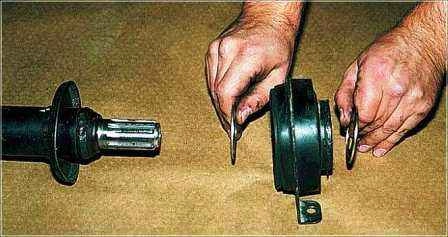

By hitting the splined shank of the intermediate shaft on the wooden lining, we knock down the intermediate support.

Remove the protective rings from the intermediate support.

Before assembling the driveline, put Litol-24 grease into the grooves of the protective ring on the side facing the driveshaft and insert the ring.

We cover the splines of the intermediate shaft with CV joint-4 grease.

Using a mandrel made of a pipe (with a diameter approximately equal to the diameter of the inner ring of the bearing of the intermediate support), we press the support onto the splines of the intermediate shaft until it stops.

We put grease on the other side of the bearing and put on the second protective ring.

Install the O-ring into the undercut of the rear driveshaft yoke.

We wrap the bolt with a lock washer put on it into the end of the shaft, having previously lubricated the threaded hole with a few drops of sealant.

After applying a sealant belt 10 mm wide to the lead-in of the splines of the front shaft, we put on the fork, aligning the previously applied marks.

Insert the U-shaped plate under the lock washer so that the protrusion on the plate fits into the cavity of the fork slot, and the tab on the lock washer into the cutout of the plate.

We wrap and tighten the bolt.

Stop the bolt by bending the protrusion of the lock washer onto its face

Gimbal Disassembly

Having washed the hinge parts with kerosene, we mark their relative position.

Prying off with a screwdriver, carefully remove the retaining rings of the bearings.

It is more convenient to disassemble the hinge with a special puller.

In its absence, we press out the bearing in a vice, for this we select a thrust ring and a mandrel from pipe sections or rings of old bearings.

We clamp the hinge in a vice so that the mandrel is located on the side of the oiler and press out the bearings

Removing the bearing assembly with cuffs from the cross, remove the fork

Similarly, we press out the second pair of bearings (the cuffs should remain in the bearing housings) and take out the cross.

In case of installing a new hinge, we wash its parts from conservation grease.

We wash each bearing separately so as not to mix the needles.

The ends of the cuffs should be chamfered, they can be made with a small needle file.

After drying the washed parts, we put the cuffs on the spikes of the cross so that the springs are facing the dirt deflectors.

Pour a little oil into the cups of the bearings and put them on the cross.

Now we remove three of them together with the cuffs, and leave the fourth (from the side of the oiler).

Further assembly of the hinge does not differ from the assembly of the hinge with parts that were in use.

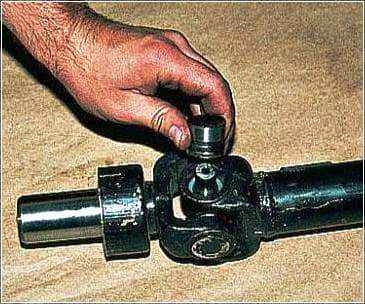

The free spike of the cross, opposite the oiler, is inserted into the eye of the fork, and then the opposite spike with a bearing and a retaining ring put on it - into the opposite eye.

We put the bearing on the free spike by inserting it into the hole of the fork eye.

After making sure that both bearings are directed into the holes of the fork, we clamp the hinge in a vise, placing a thrust ring between the jaw of the vise and the eye of the fork.

We press the bearing on the side of the oiler until the lock washer touches the fork eye.

We put the second locking ring on the opposite bearing.

We assemble both halves of the hinge in the same way, but do not forget to restore the relative position of the forks according to the marks made before disassembly.

When assembling the rest of the hinges, install the crosses so that the grease fittings of all the hinges are located in the same plane and on the same side of the hinge.

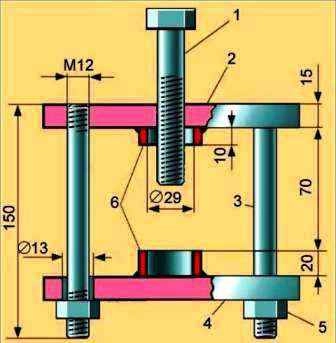

Device for dismantling universal joints

Disassembly of any cardan joints will be easier and more convenient if you use the tool shown in the figure.

Device for disassembling cardan joints: 1 - M14x70 bolt; 2 - upper support plate; 3 - coupler (2 pieces); 4 - bottom support plate; 5 - nut M12 (2 pcs.); 6 - pipe sections with an inner diameter of 29 mm

The distance between the base plates is selected depending on the dimensions of the hinge.