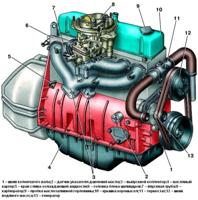

The car is equipped with two rectangular headlights with a AKG12-60+55-1 double-filament halogen lamp, 55/60 W (low/high beam) and a 4 W side light A12

On some cars, an electric headlight corrector is installed, which regulates the direction of the beams depending on the load of the car.

The electric corrector control knob is located on the instrument panel on the left side.

Side lights, instrument lighting and headlights are switched on by the central light switch, which has a resistor to adjust the brightness of the instrument lighting.

Headlights from dipped beam to high beam are switched by the left steering column switch.

Changing bulbs, removing headlights

To replace the bulbs in the headlight with the ignition off, turn the headlight cover counterclockwise and remove it.

To replace the headlight lamp, remove the connecting block from the terminals of the dipped beam - high beam lamp.

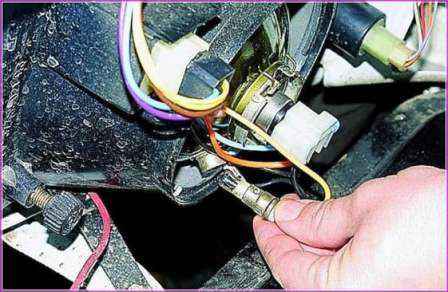

We remove the antennae of the spring retainer from the grooves

Removing the faulty lamp.

Install the new lamp in reverse order.

The halogen lamp must not be handled by the glass bulb, so as not to leave fingerprints.

If this happens, wipe the lamp with alcohol. Otherwise, the lamp bulb may darken when turned on.

To replace the side light bulb, remove the socket

Slightly pressing on the bulb of the lamp and turning it counterclockwise, we take out the lamp

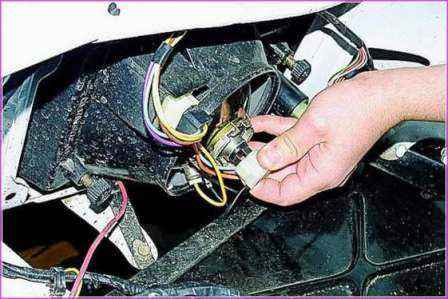

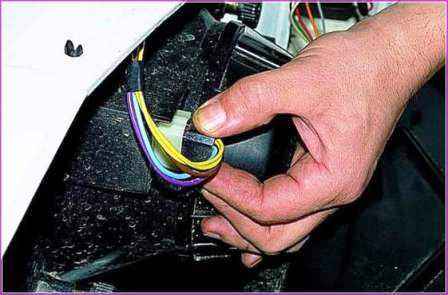

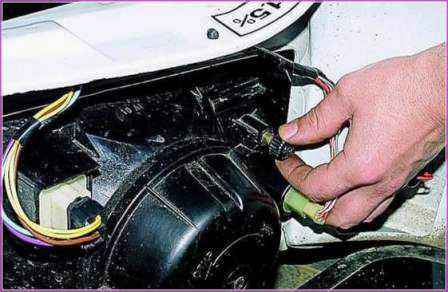

To remove the headlight assembly, disconnect the connecting block of the lamp power wires

Disconnect the headlight range control electric drive block.

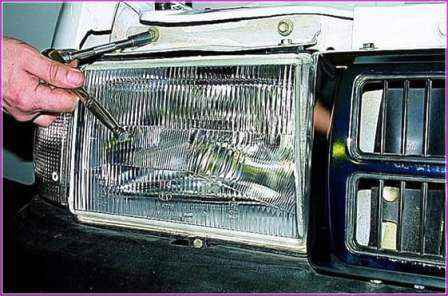

With a “10” head, we unscrew the headlight mounting bolt in the engine compartment.

Use the "10" key to unscrew the two bolts

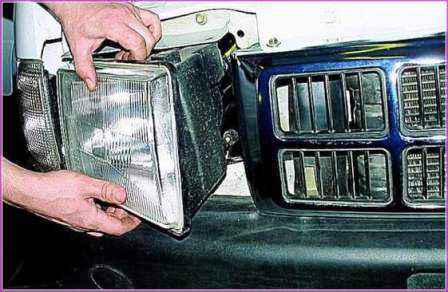

Remove headlight

If the bumper interferes with removing the headlight, first use the “10” head to loosen the two bolts securing the headlight bracket to the body

Install the headlight in reverse order.

Before by tightening the fastening bolts, we adjust the position of the headlight housing relative to the car parts mated with it.

After assembly, we check the adjustment.

Replacing the electric headlight corrector and control unit

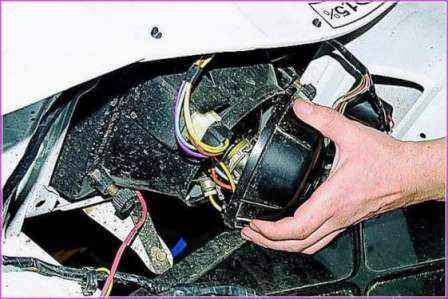

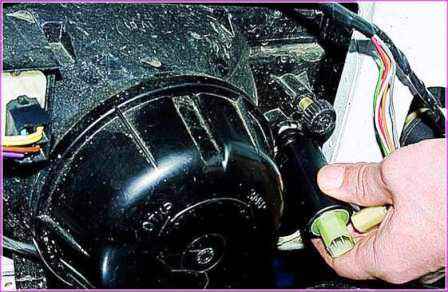

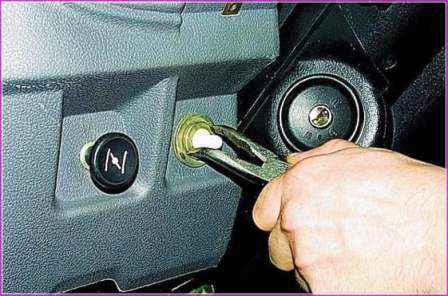

Disconnect the connecting block from the corrector pins.

Push your finger on the latch located on the drive housing (shown on the removed device)

Turn clockwise, remove the electric corrector.

After installing the electric corrector, we adjust the headlights (see Headlight adjustment).

To replace the control unit, we remove the instrument cluster (see Removing the instrument cluster).

Disconnect the connecting block from the block.

Pull it towards you and remove the control handle of the block.

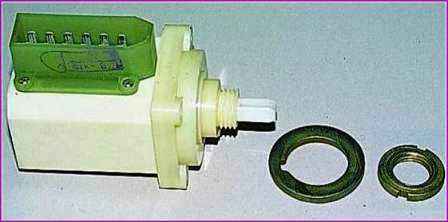

Unscrew the nut with round-nose pliers, remove the washer and block.

General view of the control unit with mounting details

Install the removed parts in reverse order

Headlight adjustment

We check the correctness of the headlight adjustment by the location of the light borders on the screen.

It is more convenient to adjust the headlights at night or in cloudy weather.

We check and adjust on a flat horizontal platform.

As a screen, you can use a sheet of plywood (approximately 1.0 m high and 1.7 ... 2.0 m long), a light-colored wall of a building, a gate, etc.

A fully refueled car, with a jack, a tool and a spare wheel fixed in regular places, we put it perpendicular to the screen at a distance of 5 meters between the headlights and the screen.

Check and, if necessary, adjust the tire pressure to normal.

For fine adjustment, you can put an assistant in the driver's seat and rock the car several times, pushing it from the side to self-adjust the suspension.

The body will then take the desired position relative to the wheels.

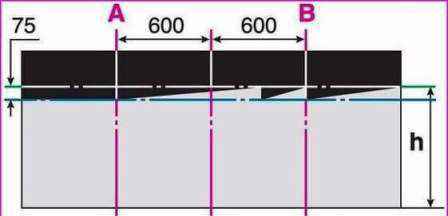

Let's mark the screen with chalk, as shown in the picture.

Dimension "h" should correspond to the distance from the surface of the platform to the center of the headlights.

If the car is equipped with an electric headlight corrector, turn its control knob clockwise until it stops.

We close one of the headlights with a piece of cardboard or cloth and turn on the low beam.

Turning the adjusting screw located on the rear wall of the headlight from the side of the radiator, we combine the break point of the light beam (the intersection of the horizontal and inclined boundaries) with the vertical line of the center of the headlight.

Turning the second adjustment screw located in the opposite upper corner of the headlight housing, we combine the horizontal border of the light beam with the bottom line on the screen

In the same way we adjust the second headlight.