Checking and adjusting the wheel alignment is necessary to ensure good stability and controllability of the car, uniform tire wear during its operation

Checking and adjusting the wheel alignment angles is performed on special stands according to the instructions for their operation.

The discrepancy between the actual values measured on the car and the reference values indicated below is due to wear and deformation of suspension parts, deformation of the body.

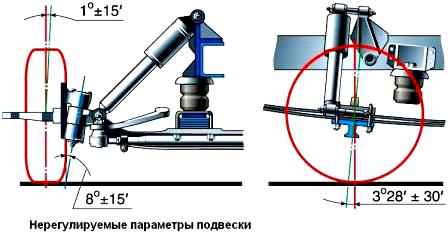

The angle of inclination of the pivots back is provided by the design of the front axle and is not adjustable.

When the load on the car increases, the angle of inclination of the pivots back increases due to the deflection of the springs.

For a loaded vehicle, this angle is 3°30'±30'.

The difference between the angles of inclination of the left and right pivots should not exceed 30'.

During the operation of the car, the angle of inclination of the pivots back may change due to deflection or twisting of the beam, breakage or significant settlement of the front springs, wear of the pivots, bushings, etc.

To restore normal kingpin back angle, replace warped or worn parts.

In rare cases where replacement of parts does not completely eliminate angle deviation, use a steel wedge inserted between the spring pad and the front axle beam platform.

If spacers are used, they must be securely attached to the beam.

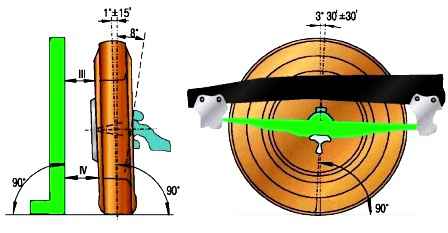

The camber is not regulated, it is provided by tilting the steering knuckle trunnion within 1°±15' to the road plane.

During the operation of the vehicle, the camber angle may change due to deflection of the front axle beam or steering knuckle.

Check the value of the camber angle with instruments.

If there are no necessary devices, then, using a square, measure the distance from the upper III and lower IV points of the rim to the vertical plane.

The difference between these dimensions at the correct camber angle should be within 4 -7 mm.

To restore the desired camber angle, find out the cause that caused the change in camber.

Often, such reasons are wear of the kingpins and their bushings, insufficient tightening of the front wheel hub bearings, deformation of the front axle beam.

The lateral inclination of the kingpins from the vertical is 8°. It is not regulated during operation.

Adjusting the toe of the front wheels

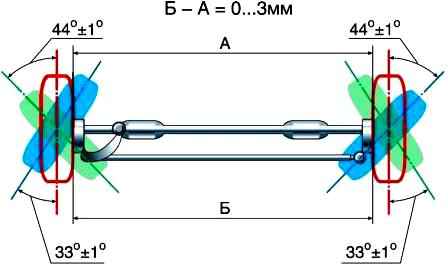

The amount of toe-in of the front wheels is determined by the difference in size between the inner side surfaces of the tires at the level of the wheel axle.

This difference should be between 0 and 3 mm.

The wheels must be in the direction of straight-line movement.

We install the car on a flat horizontal platform.

If there is no special ruler, you can measure the difference in distance between the wheels using a 1.5 m long rail and a caliper depth gauge.

- 1. We start the measurement from the front side of the wheel axle.

- 2. For greater accuracy, we mark with chalk on the tires the places between which the distance was measured.

We roll the car forward so that the wheels turn 180 ° and repeat the measurement between the points, but now behind the wheel axis.

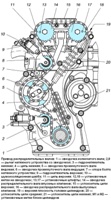

If the toe-in value differs from the norm, then with two “17” keys we loosen the tightening of both clamps of the tie rod.

By rotating the rod, we set the amount of convergence.

If the rod does not turn, we process the thread of the tips with a penetrating liquid

Check the amount of convergence and, if necessary, repeat the adjustment.

At the end of the work, tighten the bolts of the clamps.