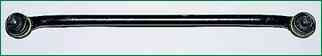

Bent steering rods must be replaced without fail, since editing this crucial steering element is unacceptable due to the fact that cracks may appear in the rod material

Removing the side bar

Hang out and remove the wheel.

To remove the right side link, turn the steering wheel all the way to the left.

Pliers take out the cotter pin

Using the “22” key, unscrew the nut securing the side link to the steering knuckle lever

Using a puller, we press the ball pin out of the lever.

A fork puller can be used.

In the absence of a puller, we do not unscrew the nut completely, insert the mounting blade into the gap between the side rod and the steering knuckle lever and strike the end of the lever with a hammer.

The ball pin can also be pressed out of the lever by inflicting a sharp blow from below with the back of the hammer on the steering knuckle lever near the hinge

Remove the ball pin from the eye of the steering knuckle lever.

Using a puller, we press the ball pin of the thrust out of the pendulum lever.

The finger can also be pressed out by applying a sharp blow from below with a hammer through a chisel with a blunt end on the pendulum arm.

Remove the right side link.

Similarly, remove the left side rod.

Install the side link so that a long tip is attached to the knuckle arm.

Having replaced the traction, we check the toe-in (see Checking and adjusting the angles of the front wheels of the VAZ-2123)

Removing the middle thrust

We carry out work on a viewing ditch or a lift.

Pliers take out the cotter pin

Using the “22” key, we unscrew the nut securing the medium thrust to the pendulum lever.

Using a fork puller, we press the medium-thrust ball pin out of the pendulum arm hole.

The finger can also be pressed out by applying a sharp blow from below (near the hinge) with a chisel with a blunt end to the pendulum lever.

Remove the ball pin from the eye of the pendulum arm.

Similarly, we press out the ball pin of the thrust from the bipod.

We take out the middle rod.

Install the middle thrust in reverse order.

The left hinge pin (inserted into the bipod hole), in addition to rotation, can swing (unlike the right one).

At the same time, when installing on a car, we orient the rod so that its longitudinal axis is in front of the hinge axes

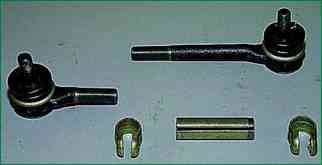

Replacing mud caps and tie rod ends

Dirt caps and tie rod ends can be replaced on the vehicle.

For clarity, these operations are performed on the removed rod.

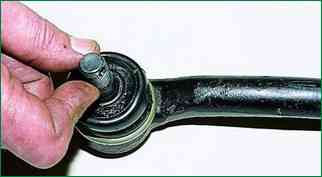

To replace the dirt cap, knock it down with a soft metal punch.

We clean the ball joint from old grease and dirt.

If traces of corrosion are found on the ball pin and the free movement of the finger in the housing is felt, we replace the ball joint with a thrust tip.

We press a new dirt-proof cap onto the hinge body with a suitable piece of pipe, relying on the metal ring of the cap.

Before replacing the rod end, we measure the distance between the hinge axes.

Using the “13” key, unscrew the nut of the coupling bolt of the clamp of the adjusting clutch, holding the bolt with a key of the same dimension.

Open the clamp with a slotted screwdriver.

Holding the adjusting sleeve with a pipe wrench, unscrew the tip (we use the pipe put on the ball pin as a lever).

Assemble the rod in reverse order.

We adjust the tips so that the rod is the same length (see photo 3).

After adjustment, tighten the clamps on the coupling. Replacing the tips, check the wheel alignment