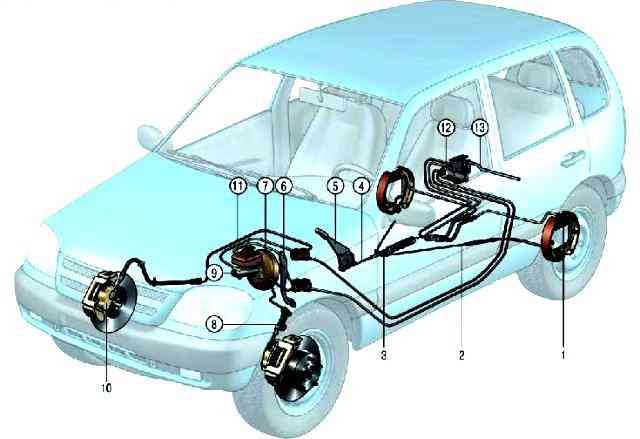

The car is equipped with two independent brake systems: working and parking (Fig. 1)

The first one provides braking when the car is moving and has a hydraulic drive, the second one slows down the car in the parking lot, has a mechanical drive.

The car has a working brake system with a diagonal separation of circuits, which significantly increases the safety of driving a car.

The first one provides braking when the car is moving and has a hydraulic drive, the second one slows down the car in the parking lot, has a mechanical drive.

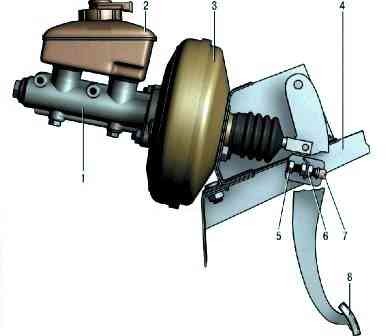

In fig. 2 shows the master cylinder 1 of the variant

One hydraulic circuit provides the right front and left rear brakes, the other - the left front and right rear.

If one of the circuits of the service brake system fails, the second circuit is used to stop the car with sufficient efficiency.

The hydraulic drive includes: master brake cylinder 9, vacuum booster 7, reservoir 11 of the master cylinder, rear brake pressure regulator 12, brake mechanisms of the front and rear wheels together with working cylinders and pipelines.

The parking system is driven by the brake mechanisms of the rear wheels.

Possible malfunctions of the brake system, their causes and remedies

- Cause of malfunction

Remedy

Increased brake pedal stroke

- Leakage of brake fluid from the brake cylinders

Replace broken brake cylinder parts, wash and dry pads, discs and drums

- Air in the brake system

Remove air by bleeding the system

- Damaged rubber sealing rings in the master brake cylinder

Replace the rings (if the cylinder is split) or replace the complete cylinder

- Damaged rubber hoses of hydraulic brakes

Replace hoses and bleed the system

- Increased runout of the brake disc (more than 0.15 mm)

Regrind or replace disc if less than 9.5mm thick

- Liquid leakage through the sealing rings of the pressure regulator pusher

Replace O-rings or regulator assembly

Insufficient braking performance

- Lubricating brake shoe linings

Rinse and dry the pads

- Jamming of pistons in brake cylinders

Remove the causes of jamming, replace damaged parts

- Complete wear of the brake pads

Replace brake pads

- Brake overheating

Stop immediately and let the brakes cool down

- Use of pads with inappropriate overlays

Use factory pads and recommended pads

- Loss of tightness of one of the circuits (accompanied by a failure of the brake pedal)

Replace damaged parts, bleed the system

Incomplete release of all wheels

- There is no free play of the brake pedal

Adjust pedal free play

- The protrusion of the adjusting bolt of the vacuum booster rod relative to the mounting plane of the main cylinder is broken

Adjust the protrusion of the adjusting bolt

- Swelling of the rubber seals of the main cylinder due to the ingress of gasoline, mineral oils, etc. into the liquid.

Flush and bleed the entire hydraulic drive system, replace rubber parts

- Jamming of the master cylinder piston

Check and if necessary replace the master cylinder

Braking one wheel when the pedal is released

- Kink or weakening of the return spring of the rear brake pads

Replace the spring

-Seizure of the piston in the working cylinder due to contamination or corrosion of the body

Replace slave cylinder

- Swelling of the sealing rings of the working cylinder due to foreign impurities entering the liquid

Replace the slave cylinder and bleed the hydraulic brake system

- Violation of the position of the caliper relative to the brake disc when the bolts of the guide pads to the steering knuckle are loosened

Tighten the mounting bolts, replace damaged parts if necessary

- Incorrect adjustment of the parking brake system

Adjust the parking brake

Sliding or pulling the car to the side when braking

- Jamming of the piston of the working cylinder

Check and fix the stuck piston in the cylinder

- Clogging of any steel pipe due to a dent or blockage

Replace or clean the tube

- Contamination or oiling of discs, drums and pads

Clean the brake parts

- Faulty pressure regulator

Repair or replace regulator

- Violated wheel alignment

Adjust wheel alignment

- Different tire pressure

Set the correct tire pressure

- One of the circuits of the brake system does not work (accompanied by a deterioration in braking efficiency)

Replace damaged parts and bleed the system

Increased effort on the brake pedal when braking

- Faulty vacuum booster

Replace amplifier

- The hose connecting the vacuum booster and the engine intake pipe is damaged or loose

Replace the hose or tighten the hose clamps

- Swelling of rubber cylinder seals due to the ingress of gasoline, mineral oils, etc. into the liquid.

Replace rubber parts, flush and bleed the system

Brake squeak or vibration

- Weakening of the return spring of the rear brake pads

Check and if necessary replace the return spring

- The appearance of ovality of the brake drums

Waste the drums

- Lubrication of friction linings

Scrape the overlays with a wire brush using warm water and detergent. Eliminate the causes of fluid or grease on the brake pads

- Wear of linings or inclusion of foreign bodies in them

Replace pads

- Excessive runout of the brake disc or its uneven wear (felt by the vibration of the brake pedal)

Regrind or replace disc if less than 9.5mm thick