VAZ-2123 steering with mechanical linkage and hydraulic booster

Sector ball screw steering gear with control valve.

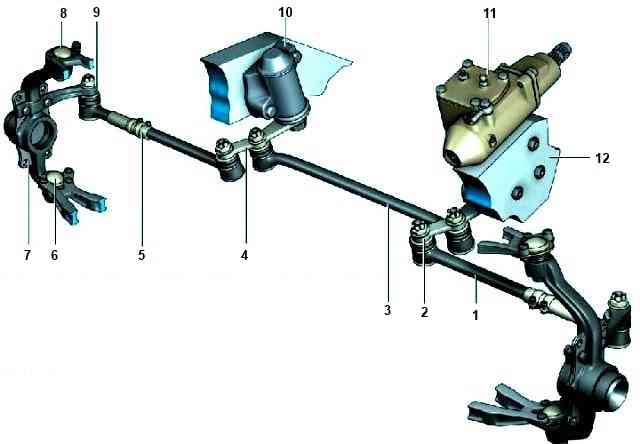

The steering trapezoid is formed by three steering rods (one middle and two lateral), a bipod, a pendulum lever and steering knuckle levers.

The side rods consist of two ends connected by a threaded split coupling.

The inner (short) tip has a right-hand thread, the outer one has a left-hand thread.

On the coupling, the threads are also of different directions, so when it is turned, the length of the lateral thrust increases or decreases, which is necessary to adjust the toe-in.

The coupling is fixed on the tips with clamps.

At the ends of the steering rods are ball joints.

Their pins are tapered into the pivot arms and secured with cotter pin nuts.

The swing arm bracket is attached to the right side member with two bolts and self-locking nuts.

Two bearings are installed in the bracket body, in which the axis of the pendulum arm rotates.

The hydraulic booster system includes: a vane pump, a reservoir for working fluid, a radiator for cooling the working fluid, hoses for supplying and discharging fluid and a steering mechanism.

The steering gear is attached with three bolts with self-locking nuts to the left side member.

The pump is mounted on a bracket on the left side of the engine.

The pump shaft is driven by a belt from the accessory drive pulley.

The hydraulic fluid from the reservoir is supplied by a high-pressure pump to a distributor located in the steering gear and mechanically connected to the steering column shaft.

When the steering wheel is turned, the distribution valve connects one of the cavities of the power cylinder to the pump discharge line, and the other cavity to the drain.

The power cylinder converts the pressure drop into an additional force acting through the piston nut on the bipod sector of the steering trapezium and then on the front wheels.

From the drain cavity, the liquid flows through the hose to the hydraulic booster radiator, where it is cooled.

Next, the hydraulic fluid enters the tank.

If the amplifier fails, the ability to drive the car is preserved, but the effort on the steering wheel is increased.

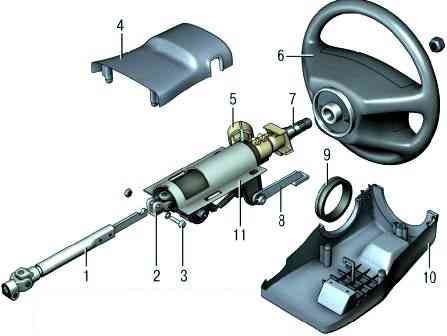

The steering shaft is two-link, consists of an upper steering shaft and an intermediate one.

The upper shaft rotates on two bearings mounted in the shaft bracket tube.

The steering wheel is fixed on the upper splined end of the shaft with a self-locking nut.

The intermediate shaft has cardan joints at the ends with split splined tips, tightened by bolts; the lower one is connected to the steering screw shaft, the upper one to the upper steering shaft.

The safety of steering is ensured by folding the steering shaft due to cardan joints and a special fastening of the steering shaft bracket.

Steering - safety with steering mechanism 11 (Fig. 1), which is a worm gear.

The steering mechanism is equipped with a hydraulic booster (Fig. 2), an electric booster can be installed on some cars

Alternatively, the car may not be equipped with power steering.

The steering drive includes three rods - the middle one 3 (see Fig. 1) and two side rods 1, as well as a bipod 2, a pendulum lever 4 with a bracket 10 fixed on the right side member, and rotary levers 9 of the steering knuckles 7.

The steering column shaft is composed of two parts - the intermediate shaft 1 with a hinge (Fig. 3) and the shaft 7 of the steering column.

At the upper end of the shaft 7, a steering wheel 6 is fixed on conical splines, and a cardan joint 2 is installed at the lower end.

Possible malfunctions of steering without hydraulic booster, their causes and remedies

- Cause of the malfunction

Remedy

Increased steering wheel play

- Incorrect adjustment of the side clearance of the steering mechanism

Adjust the backlash of the steering mechanism

- Wear of steering trapezoid ball joints

Replace ball joints

- Pendulum arm bearing wear

Replace pendulum arm

- Loosening the bipod mounting nut

Tighten the nut

- Loosening the steering wheel nut

Tighten the nut

Steering mechanism sticking

- Incorrect adjustment of the side clearance of the steering mechanism

Adjust the backlash of the steering mechanism

- Roller or worm wear

Replace worn parts

Oil leaking from the steering box

- Wear or damage to the working edge of the oil seals

Replace defective oil seals

- Increased oil level

Restore the correct oil level

- Damage to the gaskets or loosening of the crankcase cover bolts

Replace gaskets or tighten cap bolts

Noise (knocking) in the steering

- Lack of oil in the steering housing

Remove the cause of the oil leak and refill the crankcase with new oil

- Destruction of the working surfaces of the worm and roller

Replace damaged parts

- Increased clearance in the pendulum arm bearings

Replace bearings or swing arm/bracket assembly

- Increased clearance in the ball joints of the steering rods

Replace ends or tie rods

- Loosening the nuts of the ball pins of the steering rods

Check and tighten nuts

- Loosening of the bolts of the steering gear or swing arm bracket

Check and tighten bolt nuts

- Loosening the swing arm nuts

Tighten the nuts

- Loosening of the steering shaft mounting bolts

Tighten the bolt nuts

- Increased clearance in the front wheel bearings

Adjust the gap

Vibration and shocks felt on the steering wheel (with serviceable wheels and normal tire pressure)

- Steering mechanism not adjusted

Adjust the steering mechanism

- Loosening the nuts of the coupling bolts of the universal joints

Tighten the mounting nuts

- Backlash in the ball joints of the steering trapezoid

Replace ball joints

- Loosening the fasteners of the steering parts

Check and tighten loose steering parts

Moving the car away from a straight line in any direction

- Unequal tire pressure

Check and set normal pressure

- The angles of the front wheels are violated

Check and adjust wheel alignment

- Different settling of the front suspension springs

Replace bad springs

- Deformed steering knuckles or suspension arms

Check knuckles and levers, replace defective parts

- Incomplete release of one or more wheels

Check the condition of the brake system

Wear of the tires of the front wheels in the form of spots

- Low pressure in the tires of the front wheels

Set your tires to the correct pressure

- Steering mechanism not adjusted

Adjust the steering mechanism

Possible power steering malfunctions, their causes and solutions

- Cause of malfunction

Remedy

Pump noise in all operating modes

- Worn pump shaft bearings

Replace pump

Increased power steering noise when turning the steering wheel

- The power steering pump drive belt slips

Tighten or change the belt

- Insufficient fluid level in the tank, as a result of which air has entered the system

Fix fluid leaks from the system, add fluid and bleed the system

- Faulty steering mechanism

Replace steering gear

The booster does not work (increased effort on the steering wheel)

- The filter element in the tank is clogged

Replace the tank assembly

- Power steering belt slips

Tighten or change the belt

- Clogged pump valves

Rinse the valves

- Liquid of low viscosity is filled in

Replace the fluid with the recommended one

Uneven effort when turning the steering wheel to the right and left

- Clogged hydraulic system

Flush the hydraulic system and steering gear. Change fluid

- The steering gear is faulty (valves are leaky or parts are damaged)

Replace steering gear

Liquid leak from the system

- Worn seals spruce cuffs

Replace cuffs

- The hoses are damaged, the clamps of their fastening are loose

Tighten clamps, replace hoses

- The gaskets and rubber seals of the pump and steering gear covers are damaged

Replace gaskets and seals

- The plugs of the technological openings of the pump are leaking or lost

Reveal plugs to restore tightness, press in new ones to replace lost ones, or replace the pump

- Increased pressure in the system caused by the pump flow valve stuck in the closed position

Remove jammed valve

(work is recommended to be carried out at a service station or replace the pump)

- Elevated fluid level in the tank

Pull out excess liquid from the reservoir