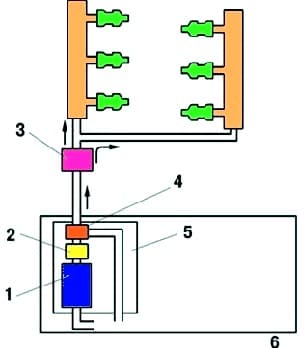

The fuel system without fuel return to the tank is used to reduce the emission of fuel vapors

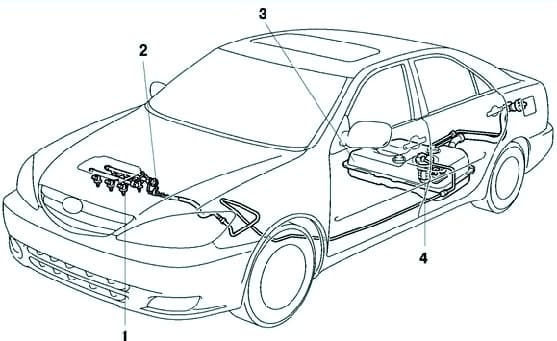

The vehicle uses a compact fuel pump (see fig. 1) in which the fuel filter and pressure regulator are combined in the fuel pump assembly.

The quick connector is used to connect the fuel line to the fuel supply hose to improve operational reliability.

Using a 12-hole compact fuel injector with a high degree of fuel atomization.

As a result, it became possible to abandon the auxiliary pneumatic system used on the previous Camry model.

The fuel filler cap has a flexible connection with the filler neck, which prevents the cap from being lost and helps prevent fuel or its vapors from leaking through the neck.

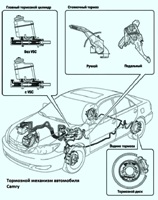

Fuel system without fuel return to the tank

This system is used to reduce fuel vapor emissions.

As shown (see fig. 2), the combination of the fuel filter, pressure regulator and fuel level sensor in the fuel pump assembly eliminated the need for fuel return from the engine and prevented fuel tank temperatures from rising.

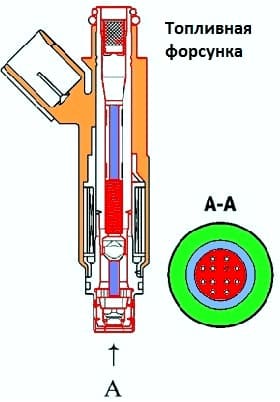

Fuel injector

The nozzle is designed for metered injection of fuel into the engine cylinder and is a high-precision electromechanical valve in which the shut-off valve needle is pressed against the seat by a spring.

When an electrical impulse is applied from the control unit to the electromagnet winding, the needle rises and opens access to the fuel to the nozzle holes - fuel is supplied to the engine intake channels.

The amount of fuel injected by the injector depends on the duration of the electric pulse.

In the holes of the cylinder head, the nozzles are sealed with rubber rings.

Using a 12-hole compact fuel injector with a high degree of fuel atomization.